MoviTHERM opens in-house NDT lab

New inspection techniques, excitation sources and infrared cameras enhance feasibility study capabilities for customers in the composites industry.

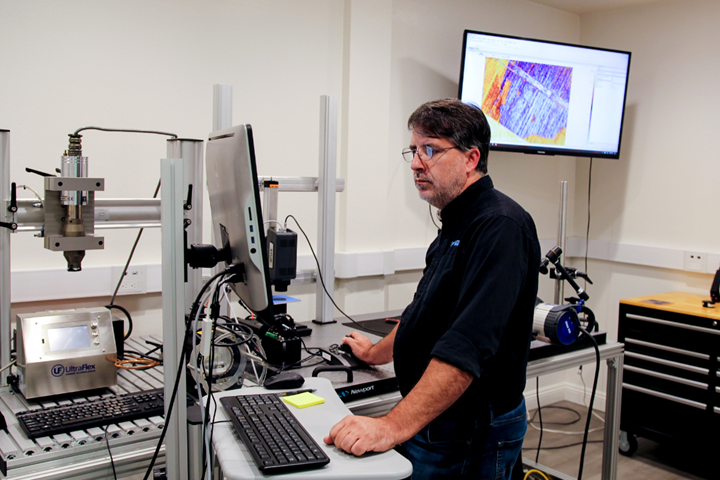

John Cabrer, senior systems engineer, conducting a feasibility study in the MoviTHERM NDT lab. Photo Credit: MoviTHERM

MoviTHERM (Irvine, Calif., U.S.) offers feasibility studies to evaluate applications under real-world conditions. The company’s recent opening of an in-house nondestructive testing (NDT) lab now enables it to support various active thermography NDT techniques. Currently working with composites manufacturers, MoviTHERM says it is hoping to continue building relationships in this space.

“Usually, customers are working with a tight time constraint. And so, we’re not just trying to figure out how we’re going to detect their defects, but how we are going to detect them quickly,” Nathan Aday, engineer at MoviTHERM, says.

With in-house studies, the company can better guide customers on what NDT method will work best for their application. “We can easily switch out the source in the same table and in the same setup do an entirely different experiment and compare the results,” Aday adds.

NDT techniques available in the lab include lock-in, pulse, transient and vibro thermography. In addition to having access to different testing techniques, the company possesses a collection of FLIR infrared cameras to compare different results. Cameras are usually the component that drives up the cost of an NDT system, MoviTHERM says. Acquiring a report with contrasting results is beneficial when deciding what NDT system to purchase.

“Because we have such a diverse set of inspection techniques, excitation sources and infrared cameras, we can try everything before we definitively say if something’s feasible or not,” Aday adds.

MoviTHERM offers feasibility testing as a low-cost and low-risk option to validate inspection applications before committing to the purchase of a complete infrared NDT system. The feasibility fee credit towards the system purchase is an added benefit of the feasibility study.

Learn more about MoviTHERM's feasibility studies.

Related Content

-

Infrared NDT well-suited to demanding in-service, manufacturing and research applications

CAMX 2023: High-precision, cost-effective thermographic NDT technologies offered by Thermal Wave Imaging addresses real-world inspection challenges.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Portable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

.jpg;maxWidth=300;quality=90)