NIAR-WSU, Victrex begin NCAMP materials and process qualification for AFP

In-depth investigation into AFP machine variability on composite allowables begins on carbon fiber-reinforced thermoplastic (CFRTP) test panels to achieve certification framework.

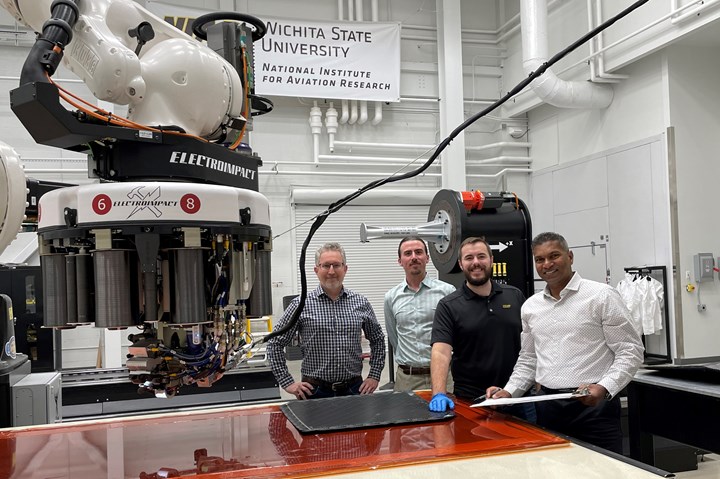

(Left to right): David Mollenhauer, AFRL; Kevin Rogers, Victrex; Isaac Schmitz and Waruna Seneviratne, WSU-NIAR. Photo Credit: WSU-NIAR

After several months of joint effort, Victrex (Lancashire, U.K. and Conshohocken, Pa., U.S.) and the National Institute for Aviation Research (NIAR) at Wichita State University (WSU, Kan., U.S.) have developed material and process specifications for automated fiber placement (AFP) systems according to NCAMP protocol.

NCAMP, the university’s National Center for Advanced Materials Performance, works with the Federal Aviation Administration (FAA) and industry partners to qualify material systems and populate a shared materials database that can be viewed publicly.

NIAR’s Advanced Technologies Laboratory for Aerospace Systems (ATLAS) has begun manufacturing test panels using Victrex AE250 polyaryletherketone (PAEK), a thermoplastic material system reinforced with IM7 carbon fibers. This is a part of the Modeling for Affordable Sustainable Composites (MASC) program, sponsored by the Air Force Research Laboratory (Wright-Patterson Air Force Base, Ohio, U.S.). MASC focuses on developing a certification framework for enabling novel materials and advanced structural concepts used for automated manufacturing technologies.

According to NIAR-WSU, this is the first time a program has conducted an in-depth investigation into the variability of multiple AFP machines on the composite allowables generated using industry-standard statistical procedures outlined in Composite Materials Handbook 17.

The project includes qualification of several thermoset, thermoplastic and dry-fiber AFP material systems from Hexcel (Stamford, Conn., U.S.), Solvay (Alpharetta, Ga., U.S.), Toray (Morgan Hill, Calif., U.S.) and Victrex. All of the data and associated documents will be included in the NCAMP shared material database.

In order to mitigate risks due to machine variability, a series of pre-qualification manufacturing trials were conducted to develop machine programming protocols to manufacture equivalent panels across various AFP machines. These machine agnostic allowables can then be used by a wide variety of certification programs regardless of the type of AFP machines used for production. The AFP panel manufacturing kickoff was witnessed by NCAMP airworthiness representatives and personnel from the Air Force Research Laboratory and Victrex.

Related Content

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.