Nikola introduces hydrogen energy brand HYLA

HYLA brand highlights integrated H2 solutions, 60 hydrogen stations installed by 2026 and access to 300 metric tons of H2 per day.

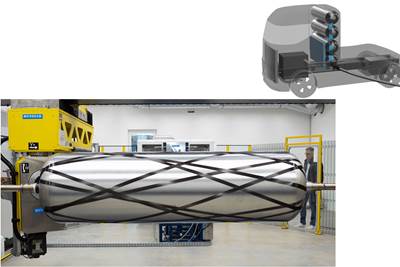

The HYLA flexible mobile fueler solution cools and compresses hydrogen to rapidly fill 700-bar FCEV heavy-duty trucks. Photo Credit, all images: Nikola Corp.

Nikola Corp. (Phoenix, Ariz., U.S.) a heavy-duty commercial battery-electric vehicles (BEVs), fuel cell electric vehicles (FCEVs) and energy solutions manufacturer, has created a new global brand, HYLA, to encompass the company’s energy products for producing, distributing and dispensing hydrogen to fuel its zero-emissions trucks.

“The HYLA brand represents Nikola’s hydrogen-focused energy business by supporting our fuel cell electric vehicles and those of other OEMs,” Carey Mendes, president, Nikola Energy, says. “Hydrogen energy is the catalyst for the HYLA brand and serves as a forward-looking solution for our customers to help them achieve their sustainability goals and dramatically reduce the overall carbon emissions in the transportation sector.”

According to Nikola CEO and President Michael Lohscheller, the company is successfully integrating the hydrogen fuel cell truck and the full hydrogen energy infrastructure supply chain under one roof. This is emphasized through the unveiling of Nikola’s Tres fuel cell truck and flexible mobile fueling trailer.

Under the HYLA brand, Nikola is developing access of up to 300 metric tons per day (TPD) of hydrogen. This supply is expected to be supported by the previously announced projects referenced below, which are being developed with Nikola partners:

- City of Buckeye, AZ Production Hub: Phased development of up to 150 metric TPD;

- Terre Haute, Indiana Wabash Valley Resources: 50 metric TPD;

- Crossfield, Alberta TC Energy: 60 metric TPD;

- Clinton County, Pennsylvania KeyState: 100 metric TPD.

-

Plug Power: Multi-region offtake agreement of up to 125 metric TPD;

Located in Buckeye, Ariz., U.S., the Phoenix Hydrogen Hub (PHH) is expected to be built in phases to scale with the demand created from Nikola’s zero-emission trucks in the Southwest region, starting with 30 metric tons in the first phase, and up to 150 metric TPD of hydrogen in future phases. Construction of the first phase is anticipated to be completed in the second half of 2024, once final investment decisions and customary regulatory approvals are finalized.

With the intent to have 60 hydrogen stations in place by 2026, the first three announced HYLA hydrogen stations will be in California in Colton, Ontario, and a location servicing the Port of Long Beach.

HYLA hydrogen stations, mobile fueler

With the intent to have 60 hydrogen stations in place by 2026 under HYLA, the first announced hydrogen stations will be in California in Colton, Ontario, and a location servicing the Port of Long Beach. California is a launch market for Nikola and these stations intend to support key customers to help advance the state’s efforts to decarbonize the transport sector.

Moreover, HYLA will highlight a flexible mobile fueler solution, an integral part of Nikola’s flexible customer service in its early years by distributing hydrogen to its FCEV customers at locations which meet their needs. The mobile fueler cools and compresses hydrogen to rapidly fill 700-bar FCEV heavy-duty trucks. Coupled with a hydrogen tube trailer with a capacity of 960 kilograms, the mobile fueler can reportedly refuel customer trucks back to back.

The mobile fueler program includes its own mobile fuelers as well as a number of third party mobile fuelers, which will provide Nikola customers with a variety of flexible fueling options.

The first mobile fueler has completed commissioning and testing and has been released for market operation. Nikola has additional hydrogen mobile fuelers being commissioned in Q1 2023.

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRead Next

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)