Share

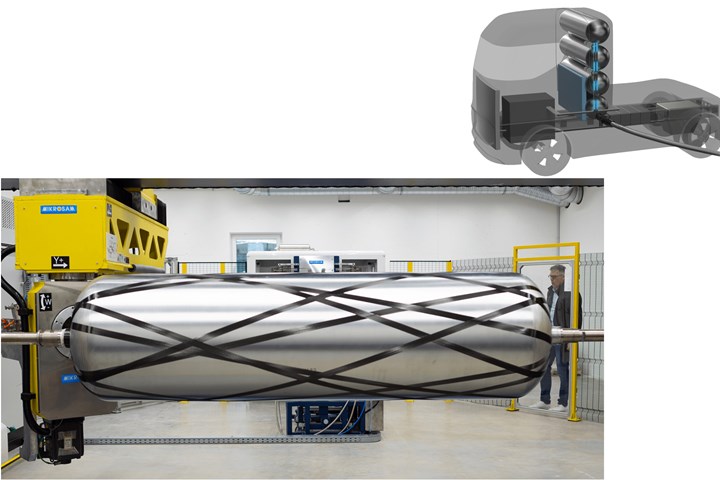

Cryomotive is commercializing cryo-compressed hydrogen (CcH2) storage tanks and refueling stations (HRS) for trucks and commercial vehicles. Photo Credit: Cryomotive

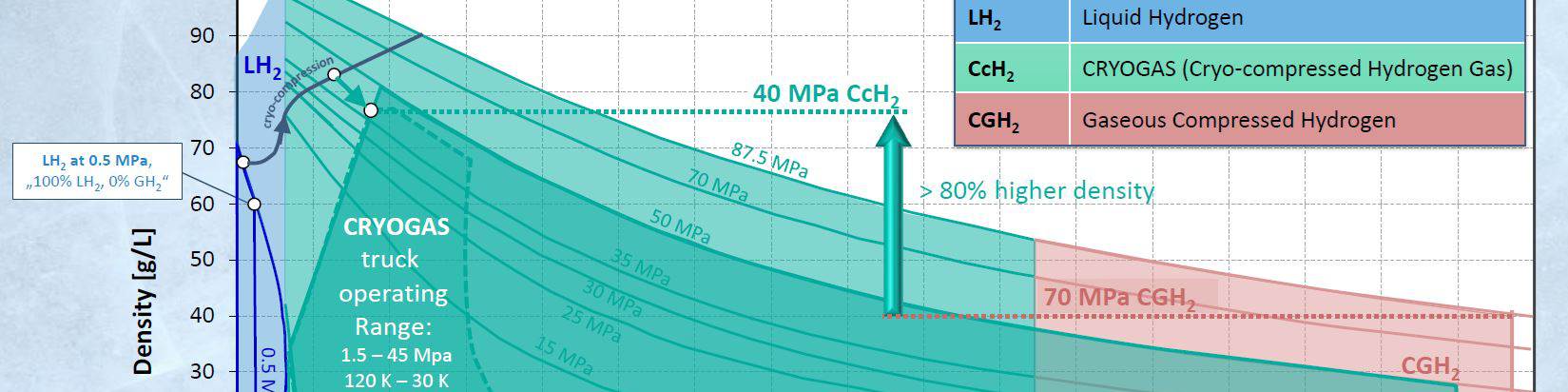

Image above title: CcH2 offers higher storage density for longer range. Photo Credit: Cryomotive

Hydrogen is recognized as a key part of the energy transition required to reduce CO2 emissions and address the growing climate crisis. In the September 2022 report “Hydrogen Insights 2022,” the Hydrogen Council highlighted 680 global large-scale projects that are investing $240 billion in hydrogen up to 2030 — an increase of 50% since November 2021. The report also quoted Tom Linebarger, executive chairman at engine manufacturer Cummins (Columbus, Ind., U.S.): “To move to a zero emissions future, we must have multiple solutions available for our customers who require vastly different applications around the world and hydrogen will play a critically important role.”

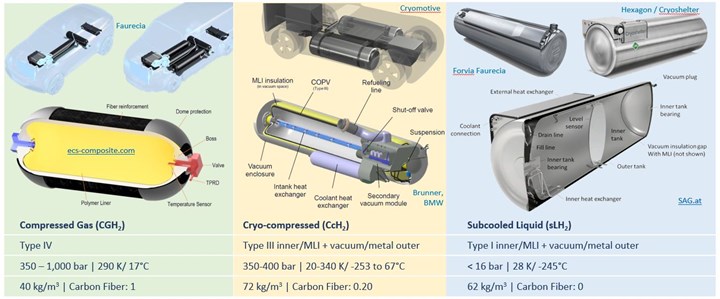

Multiple solutions will be also required within the hydrogen market, to meet the different requirements for storing and refueling passenger cars versus heavy trucks, for example, and larger versus smaller aircraft. I have written about Type IV compressed hydrogen gas (CGH2) tanks via feature articles in 2020 and 2021, while more recent articles discuss liquid hydrogen (LH2) tanks for heavy trucks and aviation (see “Demonstrating composite LH2 tanks for commercial aircraft” and “ZeroAvia advances … with LH2 in 2027”). Cryo-compressed hydrogen (CcH2) offers a third option for onboard storage tanks in transport/mobility applications.

Hydrogen storage tank types. Photo Credit: Slide 61, “Carbon Fiber Composites and the Hydrogen Economy: Opportunities and Challenges,” by Mike Favaloro, Ginger Gardiner and Jeff Sloan, Carbon Fiber 2022 conference.

CcH2 tanks at BMW

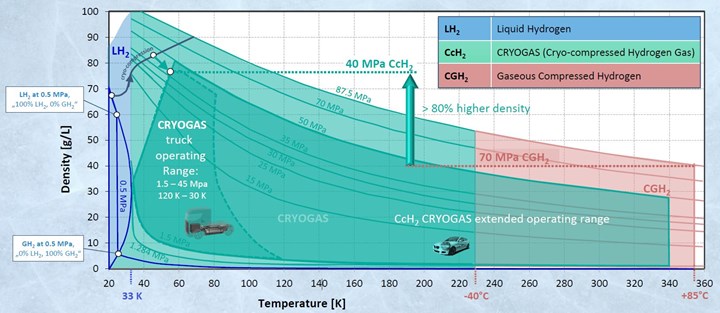

BMW CcH2 storage, cryogenic gas denser than LH2. Photo Credit: Slide 8, “Cryo-compressed Hydrogen Storage,” BMW Group presentation by Klaas Kunze and Oliver Kircher, Cryogenic Cluster Day, Oxford, U.K. Sep. 28, 2012.

BMW CcH2 storage tank. Photo Credit: Slide 9, “Cryo-compressed Hydrogen Storage,” BMW Group presentation by Tobias Brunner, Hydrogen Storage Workshop, Washington, D.C., U.S. Feb. 15, 2011.

As shown in the graphic above, CcH2 tanks offer a hybrid solution between LH2 and CGH2 storage. By using cold temperatures (e.g., 40-80K/-233°C to -193°C) and medium pressure (e.g., 350 bar), BMW eliminated LH2’s boil-off issues — LH2 boils above -253°C — and achieved storage densities much higher than CGH2 and LH2.

In presentations from 2010-2013, BMW described a prototype CcH2 system for a car that enabled <5-minute refueling and >500-kilometer range. The system used a 235-liter composite overwrapped pressure vessel (COPV) as an inner tank and cryoinsulation between this inner tank and a metal outer tank/jacket. This CcH2 tank reportedly stored 7.1 kilograms of hydrogen at 350 bar — versus 2.5 and 4.6 kilograms of hydrogen in standard 350-bar and 700-bar CGH2 tanks, respectively — with a gravimetric density of 5.4 weight% and a boil-off rate of <1% per year. The tank was elongated to fit along the car’s central tunnel.

One of the key researchers involved in that work was Dr. Tobias Brunner. In 2015 Brunner left the company. He co-founded Cryomotive (Grasbrunn, Germany) in 2020, having acquired key BMW patents to adapt its CcH2 technology for trucks, commercial vehicles and aircraft.

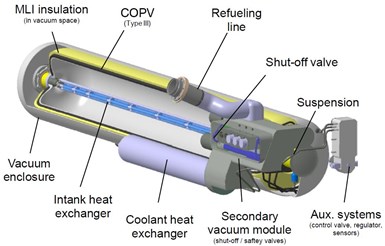

Cryomotive has already built full-scale demonstrator tanks for trucks. Once commercialized, these tanks will range from 600 to 700 millimeters in diameter and 2,350 to 2,650 millimeters in length to hold 75 to 115 kilograms of CcH2 gas in two- to four-tank system configurations. They will feature a Type III (aluminum liner overwrapped with carbon fiber/epoxy composite) inner pressure vessel encased in and separated from an aluminum outer jacket by multi-layer insulation (MLI) in a vacuum. MLI comprises multiple layers of aluminum foil and glass fiber fleece to prevent heat transfer by radiation. Nonconductive composite suspension/supports maintain the inner tank position within the outer tank.

In September 2022, Cryomotive announced it had commissioned an automated winding machine from Mikrosam (Prilep, Macedonia). “We’ve built up manufacturing capabilities because no one in the world had that available for this size of overwrapped tanks for trucks,” says Brunner. “We’ve also developed a new HRS concept with new pumps and a new nozzle that we developed with a partner. It's the highest capacity nozzle in the world at 15 kilograms/minute and yet quite compact. ”

Cryomotive is targeting first commercial applications in heavy trucks by 2025, scaling to produce hundreds of CcH2 tanks by 2026 and thousands of tanks by 2027. “The technology could also be a perfect solution for smaller aircraft and small ships,” notes Brunner.

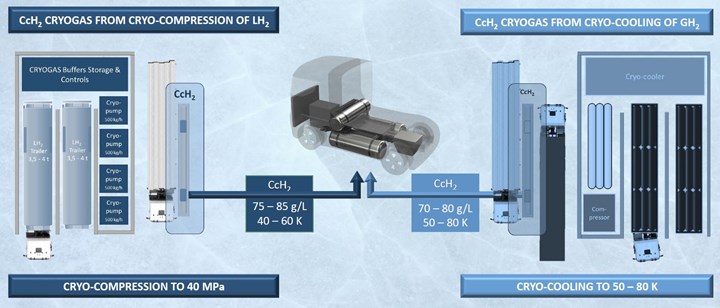

CRYOGAS can be used to fill an onboard CcH2 storage tank by either cryo-compressing liquid hydrogen (LH2) or cryo-cooling gaseous hydrogen (GH2). Photo Credit: Cryomotive.

CRYOGAS: Between the two extremes

Brunner explains that a cryo-compressed hydrogen storage system “is an insulated pressure vessel that you overfill with cold H2 gas — what we call CRYOGAS — that has 80% higher density than ambient temperature H2 gas at 700 bar, up to 80 grams/liter.” Higher density enables storing more H2 fuel in the tank for longer range.

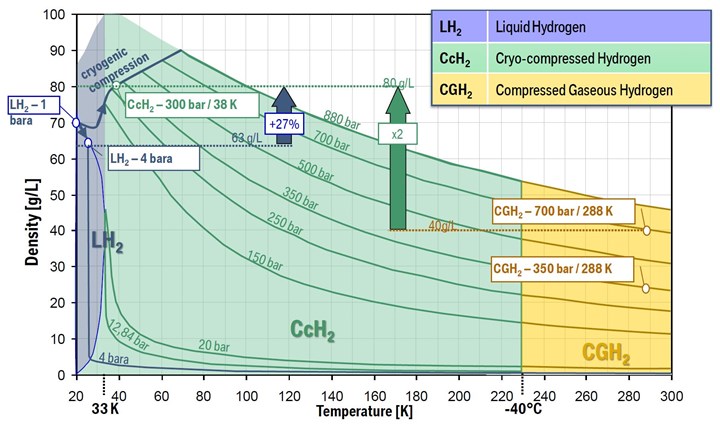

Brunner says CcH2 provides a solution between the two extremes of CGH2 at ambient temperature and high pressure (700 bar) and LH2 below its boiling point of -253°C/20 K at ambient pressure (see “BMW CcH2 storage, cryogenic gas denser than LH2” graph above).

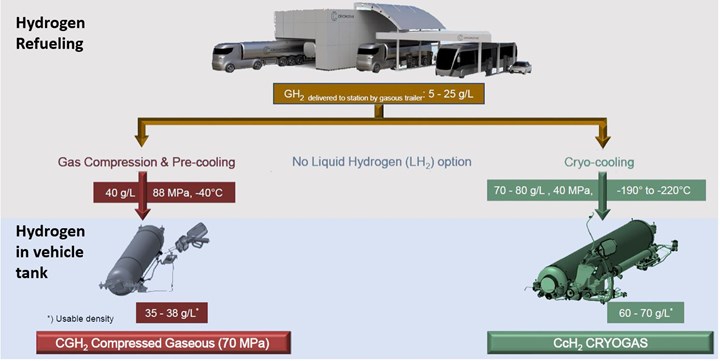

Highest density, less effort for hydrogen refueling stations (HRS). Cryomotive asserts that CcH2 not only offers the highest density for H2 in the vehicle storage tank but also requires less conditioning effort and corresponding equipment for refueling, regardless of whether the HRS is starting with compressed gas H2 (top) or liquid H2 (bottom) as a fuel. Photo Credit: Cryomotive and BMW

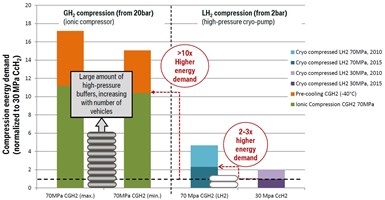

High-pressure gas, says Brunner, “demands compressed gas in the vehicle tank. To refuel, this requires a series of compressors plus a lot of high-pressure buffer tanks, as well as pre-cooling down to -40°C.” [See top image at right]. Pre-cooling is necessary because Type IV storage tanks must not exceed 85°C to prevent degradation of the plastic tank liner and sealings. Fast refueling increases the temperature of both the hydrogen and the liner. Thus, regulations demand CGH2 must be cooled to -40°C before it is dispensed into 700-bar tanks and to -20°C before refueling 350-bar tanks.

To give an example of the cost this entails, Brunner describes a hydrogen refueling station (HRS) concept proposed but quickly abandoned by H2 fuel cell truck manufacturer Nikola (Phoenix, Ariz., U.S.). “They proposed a solar-powered station with a refueling capacity of 8 tons of H2 gas per day,” he says. “This would have required 4,000 kilograms of high-pressure buffer tanks at a cost of $1,500/kilogram and multiple compressors at $1 million each — because no single compressor can provide direct feed at the required 5 to 8 kilograms per minute for fast refueling of heavy trucks. It also needed chillers to pre-cool the H2 gas. That CAPEX and the massive amount of energy required was a showstopper.”

Brunner adds that CGH2 at 700 bar also demands a lot of carbon fiber to contain that pressure in the vehicle tanks. This is a huge issue because not enough carbon fiber is being produced currently with the high strength required — e.g., 4.9 gigapascals, the standard established by Toray’s (Tokyo, Japan) T700 carbon fiber. “Toray fibers are literally not available these days,” he says, “and the cost has exploded. For example, for a single 700-bar tank for trucks, cost can reach $20,000 to $35,000 just for the carbon fiber.”

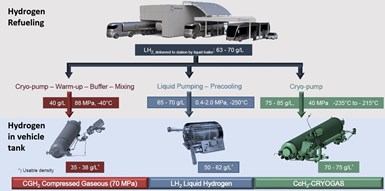

Cryogenic LH2, on the other hand, does lower HRS cost, says Brunner, “because you can store LH2 in large metal tanks and pump directly into the vehicle, but you need to cool down all the lines or you will have losses along the way and also in the vehicle tank.” The losses come from venting required to relieve pressure built as the LH2 boils into vapor.

Onboard the vehicle, LH2 is also stored in stainless steel or aluminum tanks which must be kept at cryotemperatures. Although they don’t require active cooling (e.g., powered chillers) or carbon fiber, they are not cheap. Brunner notes their heat leak must be 5 watts per hour or less. This mandates a dewar construction of inner and outer tanks — both typically metal — separated by MLI in a high-quality vacuum with pressure below 10-4 pascals. This vacuum generation requires up to two weeks of heating, says Brunner, to achieve the necessary vacuum inside, as well as multiple pipes and systems to control the flow and pressure balance of liquid to gas. Such LH2 tanks are also heavy, with past construction requiring an inner vessel wall of 3- to 4-millimeter-thick stainless steel or aluminum.

Note that Daimler Truck, hydrogen supplier Linde and Salzburger Aluminium Group (SAG, Lend, Austria) are developing LH2 tanks which they claim are thinner and more economical using subcooled LH2 (sLH2). “This is a concept,” explains Brunner, “where they fuel at a supercritical pressure up to 16 bar.” Supercritical means the pressure is above the critical point, the highest temperature along the pressure-temperature curve for liquid-to-gas phase change (see the purple region in the chart below). “Thus, they compress LH2 up to almost the cryo-compressed regime — but not to the high pressures that we use — and go into the supercritical region in order to avoid evaporation of sLH2 on the way to the vehicle. They let the pressure be reduced in the tank to 5-6 bars in a two-phase state — i.e., containing both liquid and gas — during operation.”

CRYOGAS offers a solution between LH2 (far left) and CGH2 (far right). Subcooled LH2 is shown at left in purple. Photo Credit: Cryomotive

Brunner adds he does not favor this approach, since evaporation losses at the station and onboard the vehicle can only be avoided in an optimal case of pre-conditioned tanks and station. “I developed LH2 tanks for years,” he explains. “That was my first job at BMW. And we gave it up after 35 years of research because refueling cannot be done without losses. You not only have to cool down all of the lines, but you normally need to depressurize the tank before it can take fresh LH2. Within the fleet that BMW operated, there was a significant amount of LH2 used just to cool down the system before it could be refueled.”

Why CRYOGAS is a solution

After his work on LH2 tanks, Brunner worked on developing CcH2 at BMW for more than five years. “We found that if you compress LH2 into a cryogenic gas at 30 or 40 megapascals [300 or 400 bar], you can basically increase its density,” he explains. “That was the first hypothesis that no one believed, but we built a pump with Linde and showed we could produce a high-pressure CRYOGAS at 30 megapascals with a density of 80 grams/liter compared to between 65 and 70 grams/liter for LH2.”

The graph above reflects even further development by Cryomotive for trucks. Its CcH2 system still offers higher density than LH2 while maintaining the benefits of a gas. “We don’t have a liquid that can evaporate, but instead a gas, which is inherently thermally robust,” says Brunner. “For example, when you put CRYOGAS into a warm line or tank, it just loses density and expands a little, but there is no large density change. Thus, we eliminate boil-off issues and can fuel the tank regardless of whether it is warm or cold. That concept is revolutionary and was proven to work at BMW.”

Brunner explains further, “You can basically pump fresh LH2 into the CRYOGAS and you will never lose any hydrogen. Alternatively, you can overfill it with very cold H2 gas. And when you run the vehicle, and say you empty the tank down from the triple overfill to the density of a 700-bar CGH2 tank, then you are in the gaseous region again. So, we are a gas tank all the time — just an overfilled gas tank, if you like, with very cold gas which converges to a warm gas when the tank is emptied down.”

Thus, a CRYOGAS tank is filled with CcH2 at up to 400 bar pressure, which then lowers as the vehicle drives and CcH2 is discharged. CRYOGAS tanks will deliver cold GH2 as fuel in a well-defined temperature range with an adjustable pressure up to 3 MPa (30 bar) to supply a fuel cell or H2 combustion engine, says Brunner. Similar to LH2 tanks, CcH2 tanks have an internal heat exchanger. “We can freely control the pressure level in our tanks by the internal heat exchanger,” he adds, “but decided to not go higher than 30 bar, since that would result in a warmer tank and lower average density (capacity) after refueling.”

Cryomotive refueling development

Brunner reiterates that CcH2 enables reduced HRS cost, which is a significant benefit. “The key point is our technology requires no buffers, no heat exchangers, no pre-cooling and no communication — but instead direct fueling using a reciprocating piston pump at very low cost.”

To reiterate, refueling using LH2 requires only a lower-cost pump and dispenser. However, Cryomotive also wants to offer refueling of CcH2 tanks without LH2 being available, which means using CGH2. This option does require using a CRYOGAS compressor and expander — this will likely be a single, connected device at the station — but will still not require pre-cooling, heat exchangers nor communication.

No communication? “The onboard CGH2 tank needs to have communication with the HRS to avoid overheating,” Brunner explains. “A pressure stroke at the beginning of gaseous refueling identifies the tank pressure. The system must also know the temperature outside and in the tank. A lookup table then provides the right pressure ramp and that defines the speed of refueling.” As he explained above, refueling too quickly can result in exceeding 85°C in the tank, which is not allowed. “Because that tank can be warm or cold and the ambient temperature outside can be warm or cold, communication between the station and the vehicle tank is needed to tell the station how quickly it is allowed to fill.”

“That’s not necessary for CRYOGAS because we cannot overheat,” says Brunner. “We can never end with 85°C in the tank because we operate at cryogenic temperatures, where heating due to compression is negligible due to the thermodynamic properties of hydrogen [see chart above].”

Energy consumption for compression at the HRS. Photo Credit: Slide 21, “Cryo-compressed Hydrogen Storage,” BMW Group presentation by Klaas Kunze and Oliver Kircher, Cryogenic Cluster Day, Oxford, U.K. Sep. 28, 2012.

“We can even pump at 1,000 kilograms/hour,” he continues. “We are developing such a pump with a simple design jointly with a partner. We can forecast with confidence that it can pump 500 kilograms/hour — 8 kilograms/minute — and it’s enormously cost effective — below $250,000.”

Cryomotive’s CRYOGAS refueling stations will use Fives Cryomec Hy-Filling reciprocating pump to enable unlimited back-to-back refueling of trucks, buses and other heavy-duty vehicles with 80 kilograms of CcH2 for a 1,000-kilometer driving range. Photo Credit: Cryomotive, Fives Cryomec

Cryomotive is working with Fives Cryomec (Allschwil, Switzerland) to develop and validate its Cryomec Hy-Filling reciprocating pump for CRYOGAS refueling stations. “As a worldwide leader in cryogenics, Fives has been at the forefront of hydrogen

for decades,” says Xavier Nicolas, CEO of Fives Cryomec. “We have manufactured more than 8,000 pumps ... and are looking forward to developing this new model with Cryomotive to boost green mobility for trucks and heady-duty vehicles.”

“You need only one such pump in each CRYOGAS refueling station,” he adds, “plus one liquid bulk storage and the dispenser. You can build a CRYOGAS station for less than $1 million and it can fill one truck after the other, endless back-to-back refueling. That’s why we think the technology is so vital. It has a lot of advantages onboard the vehicle, but even more advantages for the HRS.”

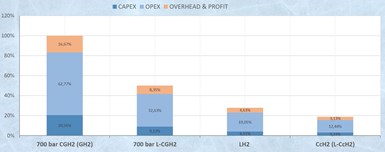

Cost for a 4 ton H2/day HRS for heavy-duty trucks. Cryomotive asserts that CcH2 refueling station costs are 1/5 that of 700 bar CGH2 stations. Photo Credit: Cryomotive

“We’ve done the cost analysis — including total cost of ownership (TCO) — CAPEX, OPEX and overhead and profit,” says Brunner. “We have 1/5 the cost versus 700-bar CGH2 delivery. So, if we need a million euros, they need five million to achieve the same capacity of 4 tons H2 per day. Even compared to LH2, which is very economical, we are still less expensive, but we don’t have their issue of H2 losses.”

FAQs

Why did BMW give it up? “Hydrogen was seen as a niche market compared to batteries for electric passenger cars,” says Brunner. “And 700-bar gas tanks were seen as sufficient. No one at that time was asking for a higher capacity storage like they are now in trucks. For BMW, the amount of carbon fiber needed for a passenger car tank was not so high because you only need to store a few kilograms of H2 gas. You still have the effort required for refueling, but compared to a truck, you only need a few buffers, a smaller compressor and a smaller pre-cooler. So, 700-bar CGH2 tanks became the mainstream.”

Isn’t the CcH2 system complex and expensive? “It is a pressure vessel with super insulation,” concedes Brunner, “but that insulation is much simpler than required for an LH2 tank. The vacuum is an order of magnitude lower so you don’t need two weeks to heat it in an oven to attain the necessary quality, and the MLI can be prefabricated and does not need to be wound around the vessel in a clean environment. We wind the composite over the liner for the inner tank, install the pre-fabricated MLI, weld the outer jacket closed and then apply the heat to attain the vacuum, which we can do fairly quickly. It’s also a more robust system. Our tanks can afford some convection and a few pieces in contact. LH2 tanks cannot. In fact, we can allow up to 10 times more heat leak than LH2 tanks.”

Is active cooling required? “No,” says Brunner. “The insulation we use is enough to keep the system cold. When you drive the truck, you discharge cold gas from the insulated tank which cools down the tank by itself — this is simply thermodynamics. And even if you make a warm filling, you drive again, and it is cooled down again and gets back into the high-density regions of the operating range. So, we never need to actively cool, but instead the system cools itself by being used and by discharging hydrogen.”

What happens if the truck sits idle? “First, the CcH2 system can absorb much more heat than a LH2 system, and a CcH2 tank can actually stand idle much longer if it is half-empty. For example, at half-full it can spend two weeks idle before venting is needed. Anyway, commercial vehicles are operated constantly, and they need a lot of energy, so that’s the perfect application for our technology.”

Are there issues in maintaining the vacuum in the tank insulation, and does it need to be rechecked? “We do need to guarantee that the vacuum is not degrading too much, but the tanks can hold the required vacuum quality long enough. Once you would have a normal service check, where you connect the tank to a vacuum gauge or pump, read the vacuum level and reapply vacuum pressure if necessary. It is also easy to monitor the pressure in situ using very simple pressure transducers. If the pressure increases, meaning the vacuum quality is getting worse, then you re-apply vacuum pressure.” Why is this shorter than during tank manufacture? “The first vacuum drawing must withdraw moisture and other contamination; with this done, redrawing vacuum will be quicker.”

Commercialization timeline

Cryomotive is working with heavy truck manufacturer MAN (Munich, Germany) as well as Clean Logistics (Winsen, Germany). “MAN also owns Navistar,” notes Brunner, “while Clean Logistics announced an order of 5,000 trucks from GP Joule in Germany, but they have also bought a truck manufacturer from the Netherlands, GINAF Nederland, to have their own platform and they are retrofitting/converting trucks as well. For both of them, we are building the same system — one tank on the left and right of the frame. This fits into any truck, because that's where you have the LNG [liquid natural gas] or diesel tanks today in the European and Asian trucks.”

Cryomotive’s target, says Brunner, “is to have these first trucks with our systems running in early 2025. And we’re working to be fully validated by then. We have done lots of cycle testing and other work toward certification. And we have also built the first stations jointly with our partner and seed investor Chart Industries [Ball Ground, Ga., U.S.] for the same timeline.”

Chart is well-established in the H2 refueling and HRS market and will offer both LH2 and CcH2 refueling and storage. “We decided that our strategy had to include both trucks and stations,” says Brunner, “because if we just build the truck’s onboard storage tanks, and no one builds stations that work with these tanks, then we lose. So, this is why we’ve had to develop very good concepts for the refueling pump and nozzle. And now we're moving to build our first station.”

Carbon fiber/epoxy overwrapped aluminum liner. Cryomotive CcH2 tanks feature a Type III inner pressure vessel and outer aluminum jacket (not shown). Here, an aluminum liner (top) is wrapped with carbon fiber/epoxy using a Mikrosam system. Photo Credit: Cryomotive

After demonstration of the first CRYOGAS station and trucks with CcH2 tanks, Brunner anticipates small series production — hundreds of systems — from mid-2025 towards 2026. “And thousands of tanks in 2027-2028,” he adds. “That’s when Daimler Trucks and all the big truck manufacturers aim to sell large numbers of H2/fuel cell trucks. Our timeline fits that pretty well. And we have the production capabilities ourselves. We know how to do it and we’re establishing how to add lines and scale up. It’s a huge investment to do all of the core component manufacturing in-house, but we don’t want to be dependent on anyone in the value chain that can slow us down.”

CRYOGAS for aviation

As stated earlier, Cryomotive’s targets include not only trucks and commercial vehicles, but also aviation. Currently, however, almost all tank development in that industry centers around LH2. Why? “Because it's lighter,” says Brunner. “We can get to 8-10 weight % [wt% = kg H2/kg tank, or storage efficiency], which is much better than the typical 5-7 wt% for a 70 MPa CGH2 tank. But really large LH2 tanks can get to 30 or 40 weight%.” That’s a big advantage for aviation where weight reduction commands a premium.

Why such high efficiency for larger tanks? Because LH2 tanks at ambient pressure increase their volume-to-surface area (V/SA) ratio with increased size. For example, as spherical tank diameter increases from 1 to 6 meters, the V/SA increases from 0.7 to 2. Scaling cylindrical tanks from 1 × 2 meters (dia. x height) to 2 × 8 meters increases V/SA from 6 to 100. Thus, more H2 can be stored versus the material needed to encapsulate it. Maximizing V/SA also minimizes heat transfer which causes boil-off.

Brunner continues, “For smaller aircraft, the tank size is smaller — holding 20 to 40 kilograms — and then CcH2 and LH2 both have 7-10 weight%. But if we talk about hundreds or thousands of kilograms, then LH2 is unbeaten in terms of storage efficiency. However, they still have all the problems onboard and during refueling in terms of boil-off and losses.”

Another disadvantage is that sLH2 tanks are best-suited for supplying into low-pressure H2 power devices, such as fuel cells at 4 to 5 bar. In order to supply into supercharged H2 combustion engines or gas turbines at 8 to 100 bar, additional compression equipment is required. “If there is only 5 bar of pressure in the tank,” he explains, “then you will need all these cryopumps onboard to increase the pressure for the engine, and they need to be redundant because there can be no failure. Our tanks, however, can provide sufficient pressure just from the tank. We don’t need a pump or active cooling. We have no losses during refueling but we are a little too heavy for large-scale aviation.”

For small aircraft, Brunner believes that CcH2 could be a perfect solution. “We can fill very quickly; we are as safe as a LH2 system and we also have the compactness because we offer higher density in the tank. We are a good fit for aviation and we have that plan.”

Cryomotive is interested in discussions with small aircraft companies, but in the meantime, it remains very focused on its timeline to commercialize its CRYOGAS tanks and stations for trucks and other commercial vehicles.

Related Content

Paris Air Show 2023 highlights

The Paris Air Show, one of the largest aerospace trade shows in the world, returned for the first time since 2019 and proved that the global aviation industry industry is very much alive and kicking.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MorePartners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

Read MoreBioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More