Novel 3D printing process achieves development of bio-based composite components

Modeling nature’s material processing techniques, research at DITF and Arburg has enabled the printing of cellulose continuous fibers reinforced with a cellulose matrix at ambient temperatures.

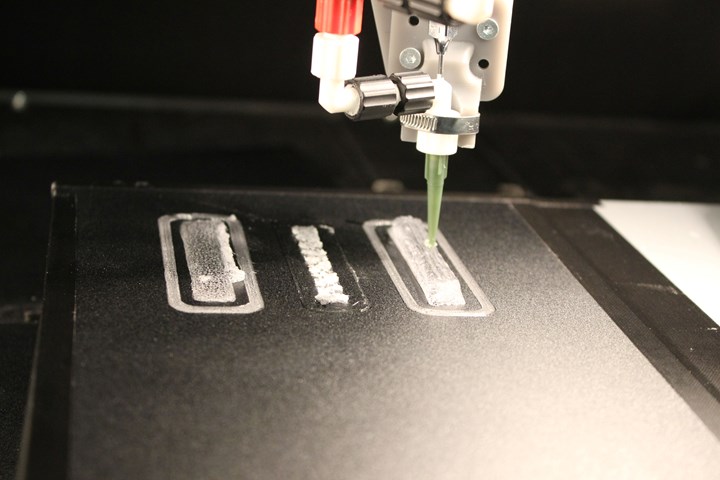

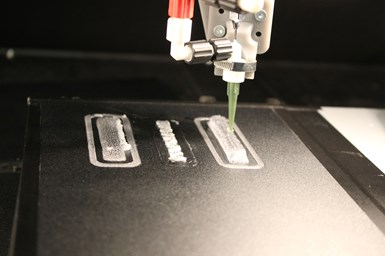

Newly developed print head for 3D printing of continuous cellulose fiber-reinforced components. Photo Credit, all images: DITF

The German Institutes of Textile and Fiber Research (DITF, Denkendorf), together with Arburg GmbH + Co KG (Loßburg, Germany), are developing an energy- and material-efficient 3D printing process for the manufacture of sustainable, bio-based fiber-reinforced composites.

In fiber composites, which occur naturally, reinforcing fibers such as collagen or cellulose fibrils are embedded in a matrix of lignin, hemicellulose or collagen. The fiber strands align with the stress patterns. Tissues are formed mostly via solution-based physio-chemical processes that take place at ambient temperature. Similar to nature, new 3D printing processes with continuous fiber reinforcement also enable the deposition of fiber strands in the right place (topology optimization) and in the appropriate direction in accordance to the load (see “Drawing design cues from nature: Designing for biomimetic composites, Part 2”). However, natural fibers such as cellulose fibers are sensitive to higher temperatures. Therefore, they cannot be processed in the commonly employed thermoplastic 3D printing process.

The result of DIFT and Arburg’s research work are 3D-printed fiber composite components consisting of cellulose continuous fibers embedded in a cellulose-based matrix. A novel 3D printing process is said to enable the manufacture of composites at ambient temperature — meaning that, like in nature, the material and component can be produced simultaneously in a single operation at ambient temperature.

The cellulose fiber strand is first stabilized with a binder for processing in the printer. The specially designed print head transforms the binder into a matrix with which the cellulose continuous fibers are encased. Since the cellulose fibers and the matrix have similar chemical structures, the composite component is said to be particularly stable. The mechanical properties, such as breaking strength, are exceptionally good.

The solution-based and energy-efficient manufacturing method developed by the research team can also be used in other composite materials manufacturing processes. It is particularly suitable for processing temperature-sensitive materials that are in high demand, such as natural or cellulose fibers.

The “CellLoes-3D-Druck” research project is funded by the German Federal Ministry of Education and Research as part of the “Biologisierung der Technik” ideas competition.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

.jpg;maxWidth=300;quality=90)