On the radar: Advancing the application, adoption of graphene-reinforced composites

Graphene, a broad 2D material family with high potential, comes to the forefront, as standardization and application efforts in the composites industry seek to break down the barrier to its commercial adoption.

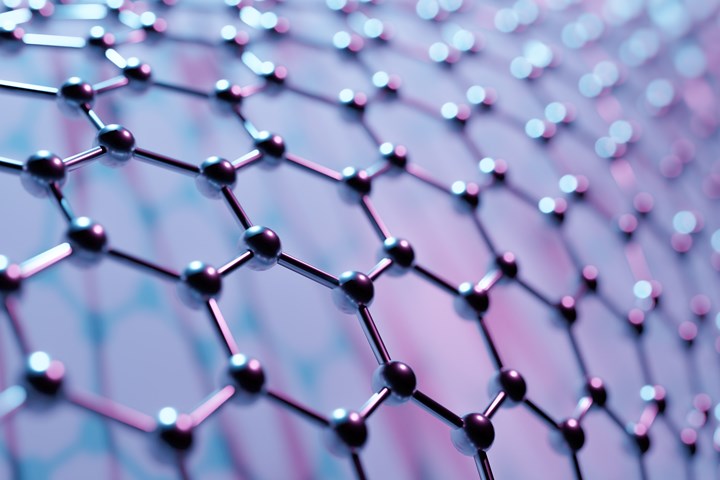

Graphene, consisting of a flexible one-atom-thick layer of carbon atoms arranged in a hexagonal lattice, is considered to be thinnest material in the world. Its diverse range of properties — from its high strength to the ability to conduct heat and electricity and absorb light to its elasticity — make graphene invaluable, not only to energy, construction, health and electronics sectors, but also within composite materials.

According to CW’s 2020 feature article on graphene, the material is “typically used as an additive within resin matrices and other materials to enhance a variety of mechanical properties, including electrical and thermal conductivity, durability, flexibility, stiffness, UV resistance, weight reduction and fire resistance.” It can also reduce interlaminar shear failure, eliminate microcracking issues, enhance impact resistance/toughness and gives some nod to sustainability.

It comes as no surprise that graphene-enhanced composites are a burgeoning area of development. Whether it’s new applications, standardization efforts or material scale-up, CW has been noticing a strong trend in graphene’s implementation and increased adoption in the composites industry:

- Specialty chemicals company Mito Materials increasingly advocates for graphene development, whether its ready-to-pour graphene resin options to reduce the complexity of adoption, or the company’s work spearheading ISO standardization efforts for a new maturity threshold. In 2022, the company’s E-Go product also earned Verified Functionalized Graphene from The Graphene Council.

- Graphene nanotubes — graphene sheets rolled into a tube — are often used by OSCiAl to advance a variety of end markets, including enhancing the dielectric properties of glass fiber-reinforced polymer (GFRP) pipes and advancing electric vehicle (EV) battery packs.

- ChemQuest Technology Institute is collaborating with Universal Matters to support the growth and validation of its graphene technology based on sustainable feedstocks.

- Swinburne’s university and industry collaboration seeks to create graphene-based nanomaterials to create a working prototype of a smart carbon fiber structure with wireless connectivity.

- Rice University is developing a method to convert crude oil byproduct into graphene, to then be mixed with composites for thermal, anti-corrosion and 3D printing applications.

-

Adamant Composites and Levidian are using their expertise to develop fabrics, prepreg, resin, adhesives and coatings that address challenges faces in various industries like automotive, wind and aerospace.

Graphene has also been used to enhance composite applications including carbon fiber touring skis, tool manufacture and sea kayaks.

.jpg;maxWidth=300;quality=90)