Pusan National University researchers introduce method to enhance thermally conductive composites

The proposed method has the potential to control the orientation of composite fillers without surface modification, improving thermal management.

Share

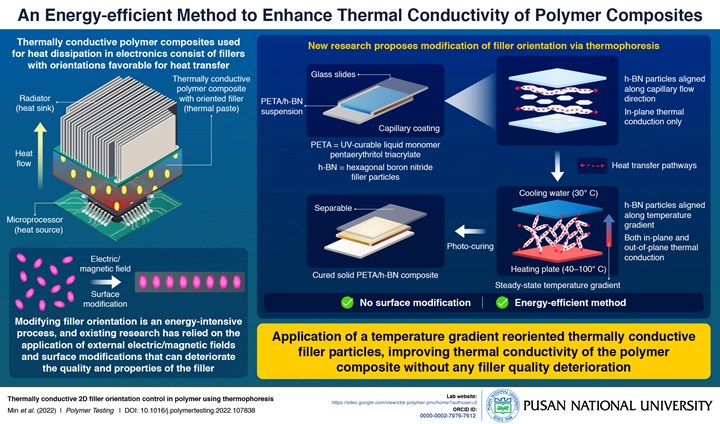

In a new study at Pusan National University, Republic of Korea, Professor Chae Bin Kim and his team have developed a more energy-efficient method to control the orientation of fillers in thermally conductive polymer composites without the need for surface modification, resulting in improvement in thermal conductivity.

Owing to their lightweight nature and flexibility, thermally conductive polymer composites are applied between a heat source and a sink in electronics to dissipate the generated heat to the surroundings. Efficient heat dissipation is achieved due to the use of fillers with certain orientations that facilitate heat flow. The conventional process of modifying the orientation of the filler material, however, is an energy-intensive process that requires the use of electric/magnetic fields and surface modifications that can compromise the filler’s quality and its thermal properties.

The university researchers’ proposed method makes use of thermophoresis, a phenomenon in which a temperature gradient causes solid particles suspended in a fluid medium to move or rotate. To prepare the polymer composite, the researchers suspended thermally conductive hexagonal boron nitride (h-BN) filler particles in a UV-curable liquid and coated it between two glass plates. A temperature gradient was applied along the film thickness, causing the filler particles to rotate and realign along the applied temperature gradient. On achieving the desired orientations, the composite was photocured, resulting in a solid composite with fixed filler orientations that form a heat transfer pathway.

“To our best knowledge, the current study is the first experimental demonstration of controlling anisotropic filler orientation using thermophoresis,” Professor Kim says.

Thermally conductive polymer composites such as thermal paste are used in phones, laptops, even in batteries. Considering the growing production of electronics and the expected transition to electric vehicles (EVs), researchers contend that the proposed method has the potential to lower the energy cost of manufacturing thermally conductive polymer composites. Moreover, by avoiding the need for surface modifications, highly efficient thermally conductive polymer composites can be developed for improved heat dissipation and extend the life of electronics.

“Efficient heat dissipating materials can ensure best operating conditions for the device with improved reliability, lifespan and user’s safety,” Professor Kim adds.

Apart from improving thermal conductivity, fillers are also used to alter a composite’s optical, electrical and mechanical properties. By offering a way to reorient the filler without any surface modifications, the proposed method can also be adopted to tune the properties of a wide range of polymer composites without deteriorating their quality.

This research, “Thermally conductive 2D filler orientation control in polymer using thermophoresis” will be published in Volume 117 of Polymer Testing on Jan. 1, 2023.

Related Content

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

-

New online training course targets prepreg basics

JEC World 2024: Composites Expert highlights how its E-Learning Composites Academy platform supports flexible industry learning with new courses developed with Stelia Aerospace North America.

-

FACC Academy begins training, onboarding operations

FACC’s newly launched training platform will address skilled aerospace worker shortages head on, offering more than 250 specialized training courses for its entire workforce.

.jpg;maxWidth=300;quality=90)