Nanocomposite films boost heat dissipation in thin electronics

Scientists from Japan develop cellulose nanofiber-carbon fiber composite films with high in-plane heat conductivity to assist in heat dissipation in electronic devices.

Share

Read Next

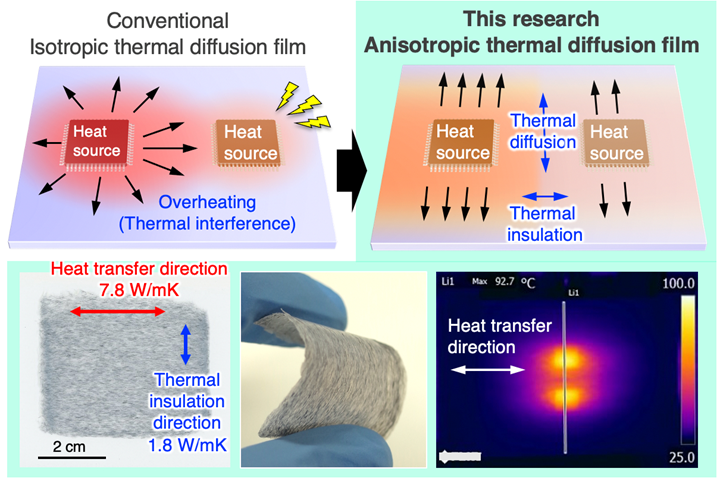

Directional thermal diffusion and insulation of in-plane anisotropic carbon fiber/CNF nanocomposite films. In a new study, scientists from Japan designed flexible thermal diffusion films made of cellulose nanofiber matrix and carbon-fiber filler using liquid-phase 3D patterning. The prepared films showed large thermal conductivity anisotropy in the in-plane direction, boosting heat dissipation and avoiding thermal interference between heat sources toward thin film electronic devices. Photo Credit: Kojiro Uetani from TUS, Japan

Heat dissipation is essential for maintaining the performance of electronic devices. However, efficient heat dissipation is a major concern for thin-film electronics since conventional heat sinks are bulky. In a recent study, “Thermal Diffusion Films with In-Plane Anisotropy by Aligning Carbon Fibers in a Cellulose Nanofiber Matrix,” researchers from Japan found a solution to this problem through the development of flexible nanocomposite films using an ascidian-derived cellulose nanofiber (CNF) matrix and carbon fiber fillers. The prepared films reportedly demonstrated excellent in-plane anisotropic thermal conductivity and the carbon fiber fillers inside are reusable.

The recent study comprised Dr. Uetani and his team, including assistant professor Shota Tsuneyasu from National Institute of Technology, Oita College, and professor Toshifumi Satoh from Tokyo Polytechnic University, both based in Japan.

The last few decades have witnessed an advance in electronics technology, with the development of devices that are thinner, lightweight, flexible and robust. However, as the devices get thinner so does the space for accommodating the internal working components. This has created an issue of improper heat dissipation in thin-film devices, since conventional heat sink materials are bulky and cannot be integrated into them. Thus, there is a need for thermal diffusion materials that are thin and flexible and can be implemented in thin-film devices for efficient heat dissipation.

Currently, several substrate materials can act as heat diffusers as thin films, but most diffuse heat in the in-plane direction isotropically. This, in turn, could create thermal interference with neighboring components of a device.

“For a substrate on which multiple devices are mounted in high density, it is necessary to control the direction of thermal diffusion and find an effective heat removal path while thermally insulating between the devices,” Kojiro Uetani, a junior associate professor from Tokyo University of Science (TUS, Japan). He researches advanced materials for thermal conductivity and formerly belonged to SANKEN (The Institute of Scientific and Industrial Research), Osaka University. “The development of substrate films with high anisotropy in in-plane thermal conductivity is, therefore, an important target.”

According to the researchers, polymer composites with thermally conductive fillers have been proposed to enhance thermal conductivity. However, there are few reports on materials with particulate or plate-like fillers that exhibit thermal conductivity anisotropy, which is important to prevent thermal interference between adjacent devices. Fibrous fillers such as carbon fibers, on the other hand, can provide in-plane anisotropy in 2D materials due to their structural anisotropy.

“We wanted to create a material that does not go to waste after usage but can be recovered and reused for further applications.”

It is also important to select matrix with high thermal conductivity. CNFs extracted from the mantle of ascidians has been reported to exhibit higher thermal conductivity (about 2.5 W/mK) than conventional polymers, making it suitable for use as a heat-dissipating material. As indicated by the ability to write with a pencil on paper, cellulose has a high affinity for carbon materials and is easy to combine with carbon fiber fillers. For example, hydrophobic carbon fiber cannot be dispersed in water by itself, but in the presence of CNF, it is easily dispersed in water. Accordingly, the team chose bio-based ascidian — sea squirt — derived CNFs as the matrix.

For material synthesis, the team prepared an aqueous suspension of carbon fibers and CNFs and then used a technique called liquid 3D patterning. The process resulted in a nanocomposite consisting of a cellulose matrix with uniaxially aligned carbon fibers. To test the thermal conductivity of the films, the team used laser-spot periodic heating radiation thermometry method.

They found that the material showed a high in-plane thermal conductivity anisotropy of 433% along with conductivity of 7.8 W/mK in the aligned direction and 1.8 W/mK in the in-plane orthogonal direction. They also installed a powder electroluminescent (EL) device on a carbon fiber/CNF film to demonstrate the effective heat dissipation. In addition, the nanocomposite film could cool two closely placed pseudo heat sources without any thermal interference.

Apart from the optimized thermal properties, another major advantage of the nanocomposite films is their recyclability. The researchers were able to extract the carbon fibers by burning the cellulose matrix, allowing to be reused. Overall, the researchers believe that these findings can not only act as a framework for designing 2D films with novel heat dissipating patterns but also encourage sustainability in the process.

“The waste that we humans generate has a huge environmental impact,” Dr. Uetani explains. “Heat transfer fillers, in particular, are often specialized and expensive materials. As a result, we wanted to create a material that does not go to waste after usage but can be recovered and reused for further applications.”

The study was published July 2022 in volume 14, issue 29 of ACS Applied Materials & Interfaces.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCarbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

Read MoreTeijin lightweight materials enable VAIO portable displays

Teijin's Tenax TPCL and Panlite Sheet materials allow for the creation of complex, three-dimensional shapes in a single molding step.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreRead Next

Alpine Advanced Materials thermoplastic nanocomposite demonstrates UV resistance

UVA and UVC testing on the aviation-grade thermoplastic nanocomposite, HX5, found no performance degradation or impact on physical appearance.

Read MoreSwinburne, Sparc Technologies researchers to create graphene-enabled smart composites

Connected smart structures are being built that can be wirelessly monitored in real time for hard-to-detect defects, enabling safer, more reliable and cheaper air and space travel.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More