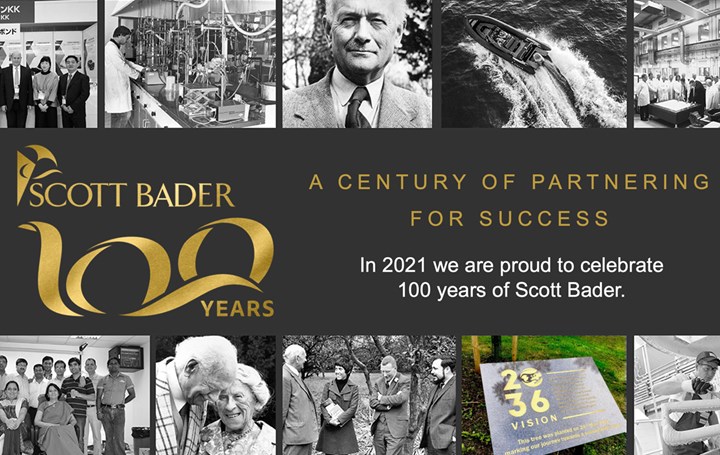

Scott Bader to celebrates 100 years as a company, 70 years employee-owned

Global manufacturer of adhesives, resins, gelcoats and functional polymers reaches company milestone, organizes a range of celebrations to recognize the company’s journey.

Photo Credit: Scott Bader

On April 28th, Scott Bader (Wellingborough, U.K.) will be celebrating a major milestone in its history — its centenary (100th) year as a global manufacturer of adhesives, resins, gelcoats and functional polymers, and 70 years of being employee-owned. Despite the pandemic, the company notes that it has adapted to organize a range of celebrations.

To recognize how far the company has come, Scott Bader has developed a comprehensive timeline on its website dedicated to capturing its 100-year journey from war-torn London, to the global enterprise it has become, serving customers from 15 offices around the world. Significant landmarks are noted, such as the move to the rural manor house in Wollaston, U.K.,

and Ernest Bader gifting the company to his employees to form the Scott Bader Commonwealth.

Details about Scott Bader’s rich history and reflections from people who have played a role over the years are documented in a Commemorative book, copies of which will be given to employees, and a digital version

made available on the website for anyone to read.

“The principles and values that Scott Bader’s founder Ernest Bader enshrined in the Constitution have fantastic resonance with the needs of the 21st century as society transforms itself onto a path that is sustainable in the long-term,” says Scott Bader’s CEO, Kevin Matthews. “To this end, Scott Bader also recognizes its own role in the transition of its customers supply chains to be sustainable and this is likely to be the main driving force for the company in the years and decades to come.”

Scott Bader says it does not have a crystal ball, but for now, the future does look promising.

Scott Bader Commonwealth Chairman, Robert Gibson, notes that “It’s

humbling and with pride to realize, 70 years on, how new and special the very ideas of Commonwealth and employee ownership were all those years ago. Generations since have benefited from the sound foundation

of principles, core values and working culture on which the company is built. We’ve come a long way and as we look forward those founding principles are as relevant today as they were at the start — and will continue. All of us in Scott Bader are a part of building a bright future.”

In 2018, Scott Bader launched its 2036 vision for a sustainable future. During its centenary year, the company has chosen to support several environmental initiatives that will both protect and reduce their impact on the environment. These include donating to the World Land Trust’s (WLT) Buy an Acre Programme for a conservation project in Argentina, and committing to the WLT’s Carbon Balanced Programme, which places a pledge on the company to reduce its carbon emissions. The intention is that these initiatives will be continued beyond 2021.

Centenary time capsules, at each Scott Bader manufacturing site will be buried by trees planted originally to mark the launch of the company’s 2036 vision. These time capsules contain employee aspirations for the future of Scott Bader by 2036 and will not be opened until then.

Further, to celebrate safely, Scott Bader employees around the world will be invited to attend a virtual celebration with videos, speeches and, of course, a very impressive birthday cake!

Scott Bader says it does not have a crystal ball, but for now, the future does look promising. One thing the company does know for certain is that in the impressive grounds of its Wollaston-based head office, a sculpture developed by metalwork artist John Creed will soon be on display representing the company’s journey.

For more information on Scott Bader’s centenary please visit here.

Related Content

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreRead Next

Scott Bader expands adhesives, gelcoats and formulated products production capacity

A newly installed mixer has increased production capacity by 30% to meet increased growth in customer demand.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More