Sicomin GreenPoxy resins contribute to first NFC wind turbine nacelle

Sicomin’s bio-based resins, intumescent FR gelcoats and UV-resistant clear coatings meet stringent requirements for Greenboats’ 7.3-meter natural fiber composite nacelle.

All photo credit: Sicomin

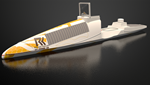

Sicomin (Châteauneuf les Martigues, France) announces its latest collaboration with Greenboats GmbH (Bremen, Germany) to deliver what is said to be the first natural fiber composite (NFC) nacelle for an offshore wind turbine, and the largest NFC structure to date. Working with German distributor Time Out Composites (Bornheim), Sicomin has provided its GreenPoxy bio-based resins, intumescent FR gelcoats and UV-resistant clear coatings for the nacelle’s development. Greenboats hopes to demonstrate how large-scale NFC structures in wind energy can lower energy consumption in manufacturing and significantly improve the sustainability of the composite materials used in the turbine.

The nacelle’s initial development stems from a commission Greenboats received in 2020 from a leading wind energy technology developer to design and manufacture a sustainable NFC nacelle. The resulting 7.3-meter-long structure has a surface area of approximately 100 square meters, and was engineered by Greenboats to satisfy all DNV-GL (Oslo, Norway) load cases required for an offshore turbine nacelle, including 200-kilometer-per-hour max wind loads and 2-kilonewton loads on the guard rails.

According to Sicomin, its GreenPoxy range was able to meeting these challenging requirements. Its DNV-GL type approved bio-based epoxy was used to infuse BComp (Fribourg, Switzerland) flax fiber reinforcements and balsa cores, with Sicomin’s intumescent weatherproof gelcoat applied on the outer surface. Cured panels were cut to shape, formed over a male plug and bonded together, before flax reinforcement plies — laminated by hand with GreenPoxy resins and vacuum bagged — were added along all panel joints lines. Finally, Sicomin’s UV-resistant clear coating products were used to protect and enhance the finish of the flax fiber feature stripe details.

“For a structure like the nacelle, it was critical that we selected materials that process consistently and perform well in large-scale components, and that is where Sicomin is so strong,” says Friedrich Deimann, founder and MD of Greenboats. “Their resins, gelcoats and clear coats meet our sustainability targets, and match our NFC ethos, with no compromise on performance. And when we need to scale up, they can really supply on an industrial level.”

According to Philippe Marcovich, president of Sicomin, the company is looking forward to the next stage of the project in spring 2021. The nacelle will be installed for testing in the Rotterdam harbor, and then permanently installed at its long-term offshore location.

“Sicomin and Time Out, our German distributor, are enormously proud of the role that GreenPoxy materials will play in the new nacelle,” he says.

Related Content

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

.jpg;maxWidth=300;quality=90)