Simcenter software update highlights aircraft wing skin optimization

Expanded aerospace capabilities in Siemens software portfolio performs more rapid margin of safety calculations and reduces simulation preprocessing up to 80%.

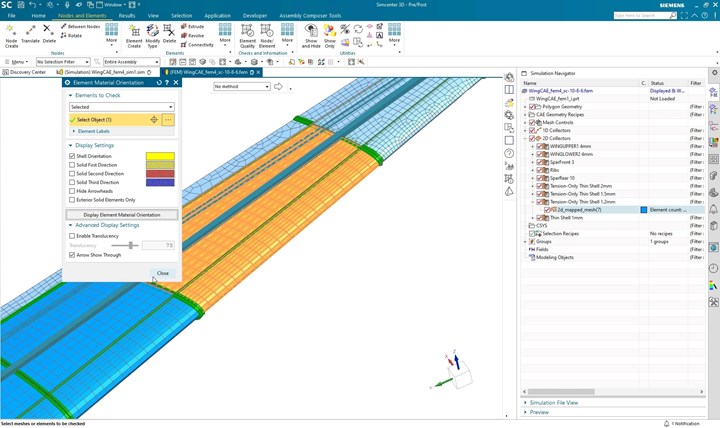

The stiffness of thin structural panels in airframe structures can change depending on whether the panels are in compression or tension. The new tension-only-quad element can convert the shells into shear panels if panels go into compression. Photo Credit: Siemens Digital Industrie Software

The latest release of Siemens Digital Industries Software’s (Plano, Texas, U.S.) Simcenter software for mechanical simulation helps streamline electrification engineering projects, assists new aircraft meet margins of safety, simplifies durability testing across many industries and much more.

“Addressing complex engineering challenges such as developing products that are more powerful, yet greener, lighter yet stronger requires a fully-integrated CAE solution,” Jean-Claude Ercolanelli, senior vice president, simulation and test solutions, Siemens Digital Industries Software, says. “The latest release of Simcenter offers a host of powerful enhancements to help engineers meet those challenges efficiently and significantly faster than ever before, whether that is getting tire contact simulations solved 45% quicker or reducing airframe structure preprocessing by up to 80%.

According to Siemens, highlights bring new functionality to the Simcenter family of products. Particularly for the aerospace industry, new capabilities reduce the number of models needed to simulate the behavior of thin aircraft skins and perform margin of safety calculations more quickly than previous releases. In addition to the new improved airframe applications, Simcenter can reportedly help engineers better understand rocket launch dynamics by simulating the liquid sloshing in fuel tanks.

A new capability in Simcenter Nastran software helps airframe engineers with thin-skinned airframe structures that have different stiffness behavior depending on the load case; tension (membrane) versus compression (shear). Today, engineers typically create multiple models and properties to account for all the different loading conditions. Siemens says the tension-only-quad will change from membrane behavior to shear behavior automatically so only a single model is needed to represent an airframe structure — reducing simulation preprocessing time by up to 80%.

Additional updates correspond to additive manufacturing (AM), automotive and industrial machinery, though Siemens says the highlights are applicable across all industries and workflows:

- Additive manufacturing: Build process simulation and review simulation results directly from remote simulations;

- Automotive: Break down electric vehicle (EV) powertrain silos/improve simulation applications, analyze wiper contact patterns and update road contact algorithm;

- Industrial machinery: Durability prediction/analysis improvements, simulating magneostriction effects, generate/calculate complex rotor dynamic circumstances.

Visit this link for greater insight in Simcenter software performance.

Related Content

-

Siemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

-

Toray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.