Swancor, Siemens Gamesa solidify recyclable wind blade partnership

Swancor will supply all recyclable resin to Siemens by 2026, contributing to RecylableBlade efforts.

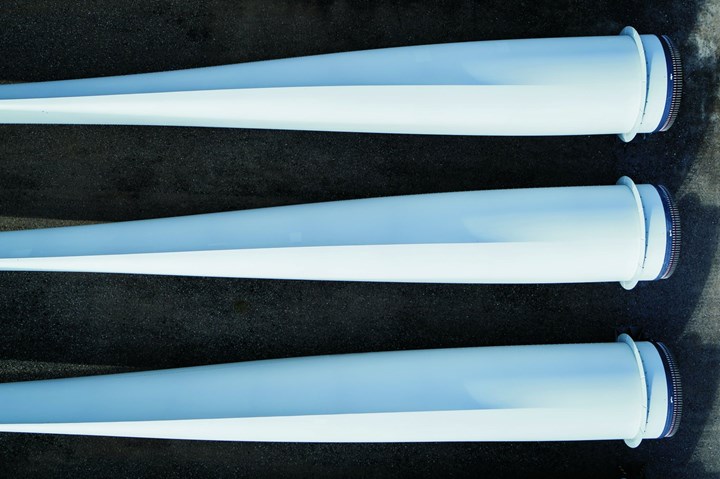

Wind power material supplier Swancor (Nantou, Taiwain) has signed a letter of intent (LOI) with its partner Siemens Gamesa (Zamudio, Spain), solidifying its collaboration on recyclable wind turbine blades originally announced in July 2022. Starting in 2026, all resin supplied from Swancor to Siemens will be recyclable.

Importantly, the partnership will strengthen Siemens’ RecyclableBlade production capacity. The RecyclableBlade is designed so that up to 95% of the blade’s raw materials can be separated and reused, advancing the company’s circular economy vision to make fully recyclable wind turbines by 2040. Some of these wind blade types have already been installed at RWE’s Kaskasi offshore wind farm.

EzCiclo, Swancor’s recyclable epoxy resin, was invented in 2021 to solve the problem of thermoset resins’ non-recyclability. Currently, EzCiclo recyclable products in commercial circulation include 100-meter wind turbine blades, carbon fiber bicycles and shoe materials. Products undergoing testing encompass dry-type transformers, copper clad laminates (CCL) and EMC packaging materials.

According to Niels Steenberg, chairman and managing director of Siemens Gamesa offshore for the Asia-Pacific. “The strategic cooperation between Siemens Gamesa and Swancor in recyclable blade resin is progressing steadily. At present, 20 pieces of recyclable blade resin have been manufactured in Denmark, and final product quality testing and certification are in progress. In the future, Swancor’s innovative technology to recycle the fiber and resin of the blades will us realize our vision of recycling all wind turbine units in Taiwan.”

Swancor has already delivered resin for more than 600 Integralblades to Siemens Gamesa as of last year.

Related Content

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

MingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

-

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

.jpg;maxWidth=300;quality=90)