TIADE research project to test blade add-ons for optimized wind turbine LCOE

New technologies and design methods for more efficient rotor operation such as spoilers, serrations, vortex generators and blade tip improvements will be applied to a full-scale, 130-meter-diameter turbine prototype.

Share

Read Next

The turbine in Wieringermeer, The Netherlands, where the full-scale tests will take place. Photo Credit: TNO Energy Transition

A consortium composed of LM Wind Power (Kolding, Denmark), GE Renewable Energy (Paris, France) and TNO (The Hague, Netherlands) released an update on project TIADE (Turbine Improvements for Additional Energy) to develop technologies and design methods for more efficient operation of next-generation wind turbine rotors, wind farms with large rotor wakes and demonstrate them in the field.

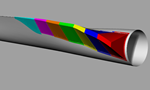

The TIADE project is said to have reached a new milestone with the research wind turbine becoming fully operational. The innovations developed in the project will be tested on the full-scale, 130-meter-diameter turbine recently installed in Wieringermeer, Netherlands, which is powered by carbon fiber two-piece blades, which allows the outer 12 meters of the blades to be replaced by several innovative tips.

“Our revolutionary two-piece blade design has helped us drive down the levelized cost of energy [LCOE],” says Ben Hendriks, chief engineer, Turbine System Integration at LM Wind Power. “Here, in this project, we are applying new technology to significantly increase speed and reduce cost associated with testing and validation.”

According to Peter Eecen, R&D manager at TNO Wind Energy, innovations in wind turbine blades are essential to make renewable wind energy even more affordable. “We are proud we will validate blade innovations and aerodynamic simulations tools in the field, together with GE Renewable Energy and LM Wind Power,” Eecen says. “Thereto advanced measurement techniques are used in a unique setup that combines detailed wind inflow measurements and unsteady pressure measurements on the blade.”

Various innovative blade add-ons, such as spoilers, serrations, vortex generators, ‘turbulators’ and blade tip improvements will be validated using advanced measurement techniques. The consortia notes that results will accelerate wide-scale application of rotors with higher annual energy production and thus a considerably lower cost of offshore wind energy (Suzlon Group recently optimized a nacelle to meet LCOE demand).

These solutions can be applied to newly manufactured wind turbines in the factory, consortium partners say, but they can partly also be retrofitted to existing offshore wind farms. With both options available, implementation of the technologies in offshore wind farms can be done from 2023.

The consortium was established in 2020 to test new research on blade tip improvements under the three-year, 10-month TIADE project, with partial funding from the ‘Topsector Energiesubsidie’ of the Dutch Ministry of Economic Affairs.

Related Content

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

MingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

-

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.