NCC research supports new composite gripper solution for wind turbine installation

Compared to current steel clamping structures, which aid in turbine installation, the feasibility study established that composite grippers could cut cost points, installation time and reduce overall environmental impact.

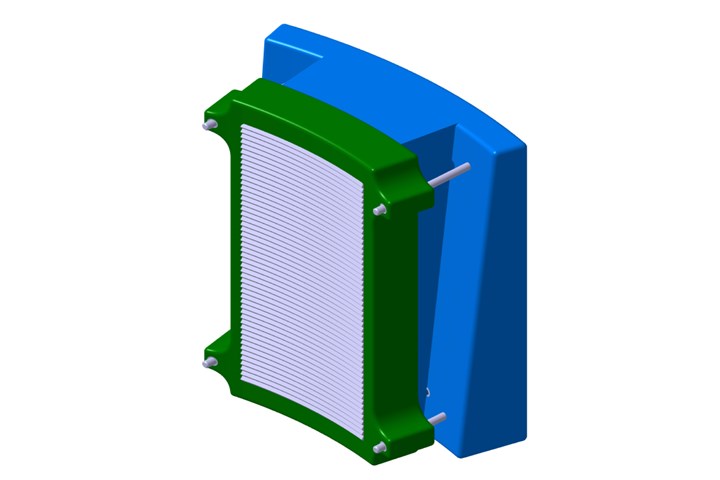

Photo Credit: Cedeco

A feasibility study conducted by the National Composites Centre (NCC, Bristol, U.K.) on behalf of Cedeco (Glasgow, Scotland) has shown that an innovative composite gripper solution could reduce the environmental impact, cost and time of installing offshore wind turbines.

Cedeco, an inventive engineering SME working in offshore oil and gas and renewables, applied funding from Offshore Wind Growth Partnership (OWG), a £100 million program supporting improvements in the U.K.’s productivity and competitiveness, to approach the NCC to investigate if composites could offer a sustainable, cost-effective, materials solution to manufacture a gripper that holds an offshore wind turbine leg in place.

According to the NCC, offshore wind turbine jackets currently sit with their legs inside tubular pile mountings in the seafloor, held in place by tonnes of grout that fills the gap between the jacket leg and the seabed pile. To aid installation, a steel clamping structure is used to hold the leg in place while the grout sets. The clamp usually remains and corrodes in place, creating seabed waste that remains for generations.

Through conceptual designs, cost modeling, material and process assessment and a life cycle assessment, engineers at the NCC established that using composite materials for the grippers could potentially decrease the targeted cost point by up to 50%, cut the installation time by up to 50 days on a 100-turbine farm and reduce the environmental impact of the turbine installation by up to 40%. Switching to a composite gripper could also remove unnecessary structures from the turbine leg and jacket and reduce the overall size of the wind turbine legs.

These factors, says the NCC, all combine to reduce the barriers currently faced when creating new wind farms. In improving the return on investment, they are a more attractive proposition for investors, and the reduced carbon footprint reduces the negative environmental impact of installing wind turbines further promoting them as an environmentally friendly power generator.

The project was funded by the Offshore Wind Growth Partnership’s (OWGP) first Grant Funding Competition, which is awarded to projects exploring advanced manufacturing solutions for offshore wind.

“As with any project, there is always some hesitation at the outset, but we are delighted with the results of the feasibility study,” says Jacqueline Morrison, commercial lead for Cedeco and IUK Women in Innovation award winner.

On working with the NCC team, Iain Steven notes that “the enthusiasm of the team was palpable with many of the outputs produced going beyond our expectations. The outcomes from the various work pages have helped cement some of the earlier work produced by Atkins while also underpinning much of the data submitted at this stage to DNV. The carbon reduction savings identified as part of the life cycle assessment are additional proof of the benefits the non-grouted connector can deliver.”

Cedeco is now applying for a IUK SMART grant with Atkins, the Offshore Renewable Energy Catapult (OREC, Glasgow, U.K.) and the University of Strathclyde to continue to develop the engineering and work towards scaled testing.

“As a micro-SME we know that our route to market will be through industry collaboration with the likes of the NCC and OWGP and working together with industry partners including a fabricator, installation contractor and wind developer,” Morrison continues. “With the help of OREC we created a commercial roadmap that sees the product coming to market mid-2025 and we are always on the lookout for new partners willing to travel with us on that journey. I'm glad we took those initial steps to apply for OWGP funding and I would encourage other companies, no matter what their size, to do the same. We're really looking forward to continuing our journey with the NCC and hopefully OWGP, too.”

Related Content

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreRead Next

Natural fiber composite wheelchair seat design aims for sustainable mobility

The National Composites Centre and Motivation provide an easily manufactured, locally sourced mobility solution for disabled people in developing countries.

Read MoreVineyard Wind offshore project receives federal approval

U.S. commercial-scale offshore wind farm design to include GE Haliade-X wind turbines for 800 MW of wind energy development in Massachusetts.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)