Toray expands high-performance composite tooling supply in U.S.

The Toray AmberTool HX56 composite tooling prepregs will be fully stocked in the central U.S. enhancing the speed of supply and regional availability. Products are available as of Sept. 22, 2020.

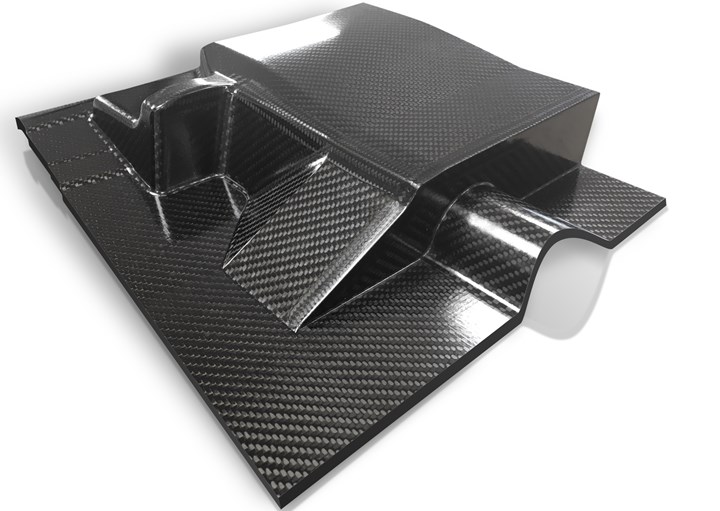

Photo Credit: Toray Advanced Composites

On Sept. 22, Toray Advanced Composites (Morgan Hill, Calif., U.S.) announced the creation of a U.S.-based distribution center for its high-performance Toray AmberTool HX56 composite tooling prepregs, enhancing the speed of supply and regional availability of its composite tooling technology. Manufactured at the company’s Thermoset Center of Excellence in the U.K., Toray says the tooling material will be fully stocked in the central U.S., allowing for immediate order fulfillment for customers in North America. Real-time delivery of composite tooling will be crucial, especially to the motorsports market, says Toray, where rapid design and production cycles also demand rapid support from suppliers. Product will be available as of Sept. 22, 2020.

According to the company, Toray AmberTool HX56 is a low temperature curing epoxy prepreg that produces an excellent surface for short-cure autoclave processing. Further, the high-performance tooling prepreg has robust handling characteristics that provide drape for complex shapes like those needed in the motorsport market. The prepreg, says Toray, has been a key enabler to the high-end motorsport market in Europe for more than 20 years. Like all AmberTool products, it is said that the AmberTool HX56 enables the production of precision composite tools with excellent accuracy and surface finish.

“Our core philosophy is to ‘outperform’ our competition on all fronts,” says Bryan Nortje, senior technical manager at Fibreworks Composites. “The HX56 Tooling system falls perfectly into our needs. It offers us faster turnaround times without compromising quality. Kudos to Toray for supporting us in the U.S.A. with this product from Europe.”

For more technical information, view the Toray AmberTool HX56 Data Sheet.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.