CAMX 2022 exhibit preview: Hexagon

Hexagon’s Digimat + Volume Graphics workflow interface delivers a robust connection between process, material and performance, enabling new advanced materials exploration.

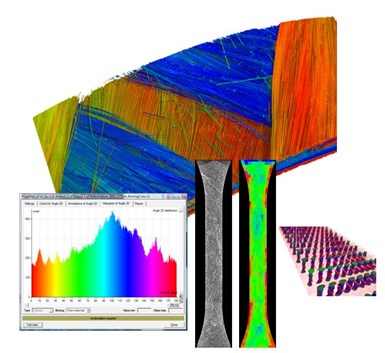

Different composite microstructures are shown here from Volume Graphics after postprocessing from computed tomography (CT) scans. The information is then passed to Digimat for finite element analysis (FEA) simulation. Photo Credit: Hexagon’s Manufacturing Intelligence division

Hexagon’s Manufacturing Intelligence (North Kingstown, R.I., U.S.) division is featuring its extensive solution capabilities to analyze and enhance complex composites and advanced materials. CAMX attendees can get a firsthand look at a new validated workflow that can be used to understand new material performance. The development of an interface between Volume Graphics and MSCOne’s Digimat software has been used to develop and ensure accurate microstructure representation in simulation and structural analysis. Volume Graphics technologies perform both computed tomography (CT)-scan postprocessing and 3D volume reconstruction using CT scans. When interfaced with Digimat’s material modeling platform, Hexagon says users can execute performance prediction of parts made out of long fiber composites, reducing time and resources in the process.

This workflow is said to successfully deliver a robust connection between process, material and performance, and has been successfully used among material suppliers and Tier 1 automotive OEMs. Equipped with the right CAE tools, engineers can explore new advanced materials in the composites arena, namely advanced composites, sandwich panels, plastics, nanocomposites, hard metals and more. Hexagon’s Manufacturing Intelligence division uses data from design and engineering, production and metrology to make manufacturing smarter. Its CAE solutions, developed through the acquisition of the MSC Software portfolio, reportedly help engineers accelerate product innovation. For more information, visit hexagonmi.com/mscsoftware.

Related Content

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

Recycled carbon veil designed to close carbon fiber lifecycle loop

CAMX 2023: Technical Fibre Products’ new nonwoven veil can be reused in composites, effectively closing the loop and providing a viable route for the recycling of fibers.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

.jpg;maxWidth=300;quality=90)