Composites, resins portfolio supports EV applications, sustainability

JEC World 2024: Huntsman is sharing a new polyurethane- and epoxy-based composites portfolio aligned with the needs of the automotive sector.

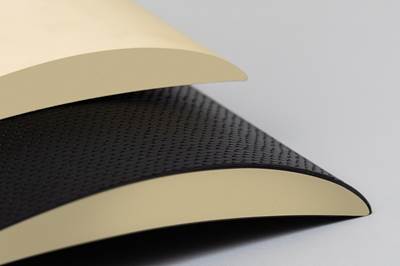

Glass mat-reinforced polyurethane seat pan illustration. Source, all images | Huntsman

Huntsman (Frankfurt, Germany) is announcing a novel polyurethane- and epoxy-based composites portfolio in early March, which features a range of technologies that can support automotive manufacturers and their Tier suppliers in optimizing production processes; reducing environmental impact; and maximizing the performance and lifetime of vehicle components as the drive for cleaner, lighter electric vehicles (EVs) continues to accelerate.

Innovations available for customers to explore will include the RimLine RSM system — a glass fiber-reinforced polyurethane composite developed for rear seat pan applications. Aligned with the needs of the automotive sector, which is increasingly reliant on composite technologies to help increase vehicle range, Huntsman’s RimLine RSM system can support compact, lightweight, simplified design configuration requirements. Enabling the potential for high part integration capabilities, the technology is applied via reaction spray molding, making it ideal for creating complex geometrical shapes. It can offer very good fiber impregnation for high surface quality. It also cures quickly after spraying and can be demolded quickly for an efficient production cycle.

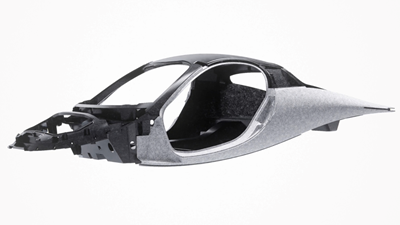

Other innovative products under the spotlight at Huntsman’s booth include a portfolio of customizable, quick-cure, high-strength polyurethane resins that can be used to house batteries in EVs. These Vitrox and RimLine systems can be used to create composite components for underbody and upper cover battery protection applications up to 30% quicker than some existing technologies, Huntsman reports. Enabling high-performing composites alongside extra design and production flexibility capabilities, the range includes products that can offer lower overall part weight and increased strength as well as improved structural performance — and were developed to be suitable for integration in EVs.

Solutions are available for wet compression molding (WCM), core molding, high-pressure resin transfer molding (HP-RTM) and long fiber injection (LFI) molding techniques, depending on end user requirements. All presented polyurethane technologies can also be offered as ISCC PLUS mass balance certified, helping to reduce attributed carbon footprint (GWP100 including biogenic CO2) by up to 50% when compared against Huntsman incumbent technologies, supporting customers working toward sustainability and net zero.

HPU battery.

A highlight will be the UN ECE R134 certified 700-bar and 350-liter Type 4 hydrogen tank manufactured by Voith Composites (read “Voith Composites certifies towpreg-wound Carbon4Tank for on-road use” for more info). The high-pressure vessel, produced via an optimized towpreg winding process, can be observed in Booth Q24 (Hall 6) or at the JEC Innovation planet. Huntsman says it has developed an efficient resin system to help enhance towpreg materials’ storage capabilities at room temperature; ensure precise rheology, tackiness and cohesion of carbon fiber filaments; and enable swift impregnation and accurate placement during high-speed winding while maintaining thermo-mechanical performance.

Huntsman also presents its latest range of epoxy resin solutions developed for composite pressure vessels at the JEC World 2024 Composite Exchange, demonstrating how it is leveraging its capabilities to support industries moving toward more sustainable solutions. The three main development routes to be presented will include:

- Mass balanced certified resin systems with up to a 100% CO2 reduction;

- New high-performance epoxy resin systems to help reduce carbon fiber use;

- Next-generation recyclable thermoset resin systems.

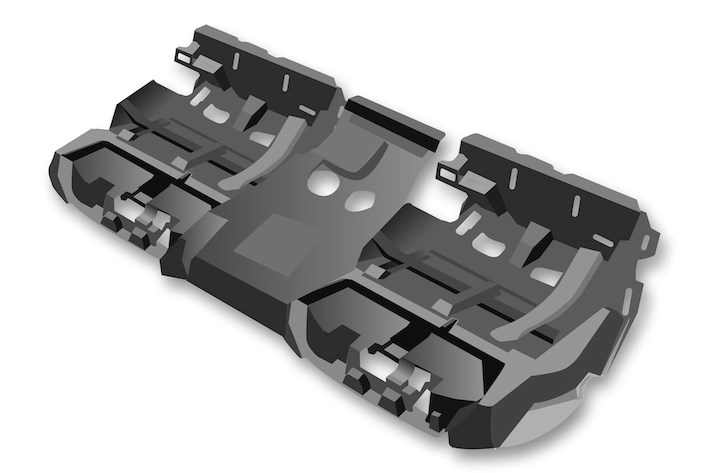

Other innovations displayed will include the latest Araldite epoxy resin systems developed for composite battery enclosures, trays and underbody shields, developed to help customers meet requirements which can include part-specific structural, fire, thermal, environmental and mass production needs. Huntsman showcases its range of intrinsic fire-retardant Araldite FST and unfilled mass production systems for WCM, RTM and HP-RTM processes that can enable short cycle times with low scrap rates.

Developed to help meet increasing demand for sustainable products and suppliers that support net-zero targets, Huntsman contends that it can offer all epoxy resin systems presented at JEC World as mass balance certified (MBC) from its REDcert2 certified production site. Araldite MBC epoxy resins can help customers reduce the carbon footprint of materials by up to 100% without compromising on performance, while avoiding lengthy and costly re-qualifications.

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Huntsman PU resin systems enable lightweight sandwich construction for automotive

Vitrox RTM and Rimline FC polyurethane systems to advance lightweighting, design freedom and simplified manufacturing opportunities.

Read MoreAptera joins forces with C.P.C. Group to accelerate solar EV production

Specialized composite bodies are being produced in Modena, Italy, for Aptera’s BinC vehicle, enabling eventual manufacturing ramp-up of 40 vehicles/day to meet demand targets.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read More

.jpg;maxWidth=300;quality=90)