Engineering Technology (Entec) revamps filament winding machinery lineup

Engineering Technology Corp. has reorganized its line of filament winding equipment into primary products, each offering different combinations of maximum mandrel weight, maximum mandrel length, mandrel diameter, number of spindles, number of axes and speed.

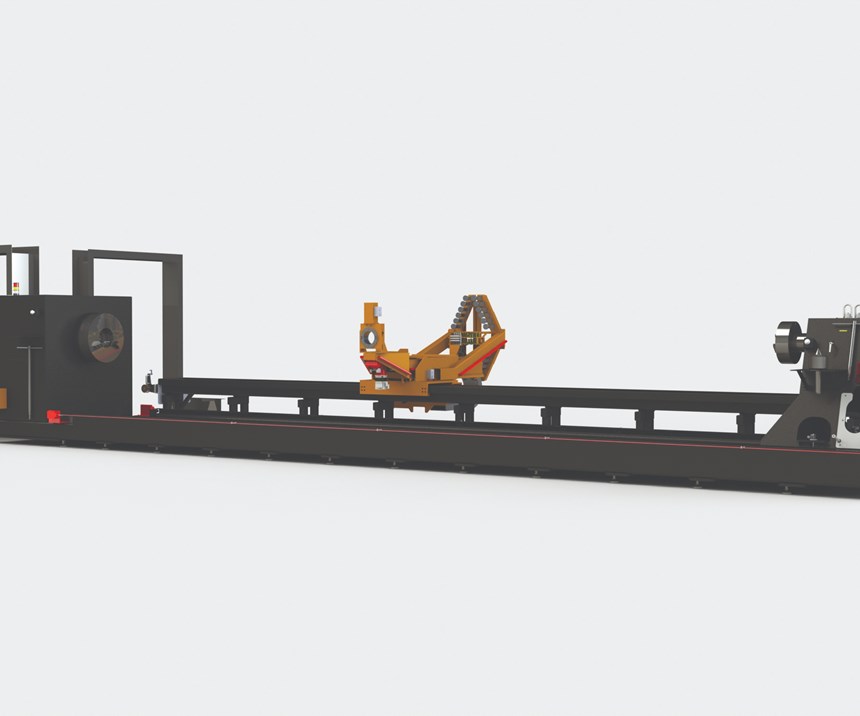

Engineering Technology Corp. (Entec, Salt Lake City, Utah, U.S.) reports that it has reorganized its line of filament winding equipment into primary products, each offering different combinations of maximum mandrel weight, maximum mandrel length, mandrel diameter, number of spindles, number of axes and speed.

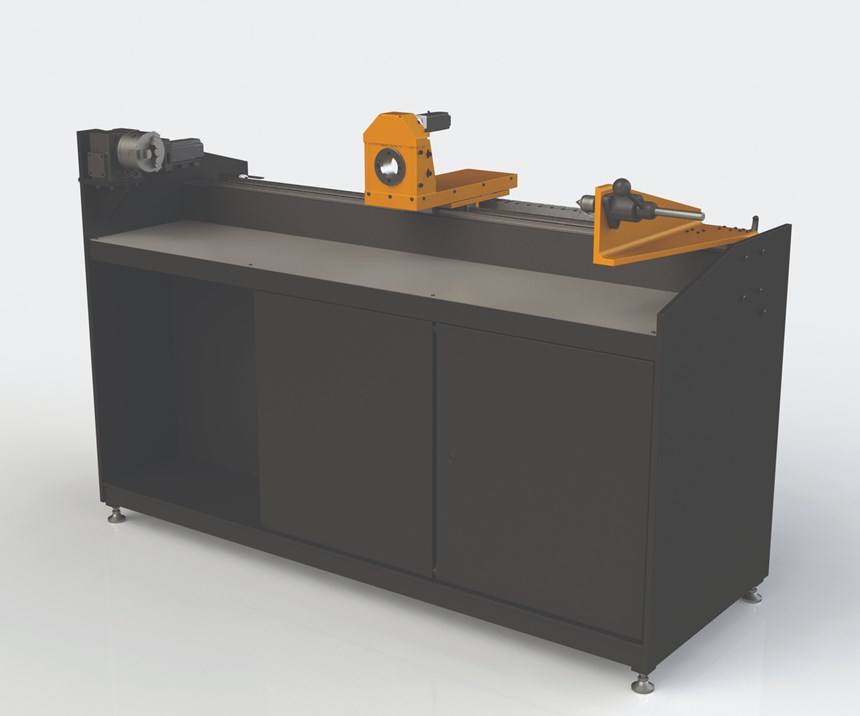

The most basic unit is the SS filament winder, designed for R&D or educational use. It can be used with wet winding or towpreg delivery and has a maximum mandrel weight of 23 kg, maximum mandrel length of 2000 mm, mandrel diameter of 23-305 mm, one spindle and two axes. The SS+, for small production environments, features an integrated cabinet and table. It has the same specifications as the SS except for a 25-205-mm diameter mandrel and three or four axes.

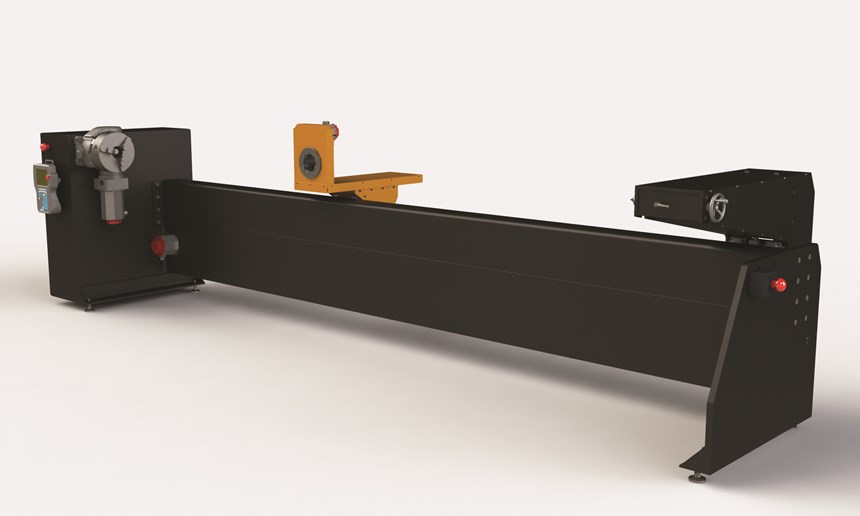

The SM, for medium envelope part production, has a maximum mandrel weight of 340 kg, maximum mandrel length of 5000 mm, mandrel diameter of 25-610 mm, one spindle and two to four axes. The SM+, for medium envelope part production at high volumes, has a maximum mandrel weight of 454 kg, maximum mandrel length of 6000 mm, mandrel diameter of 25-914 mm, one to eight spindles and two to five axes.

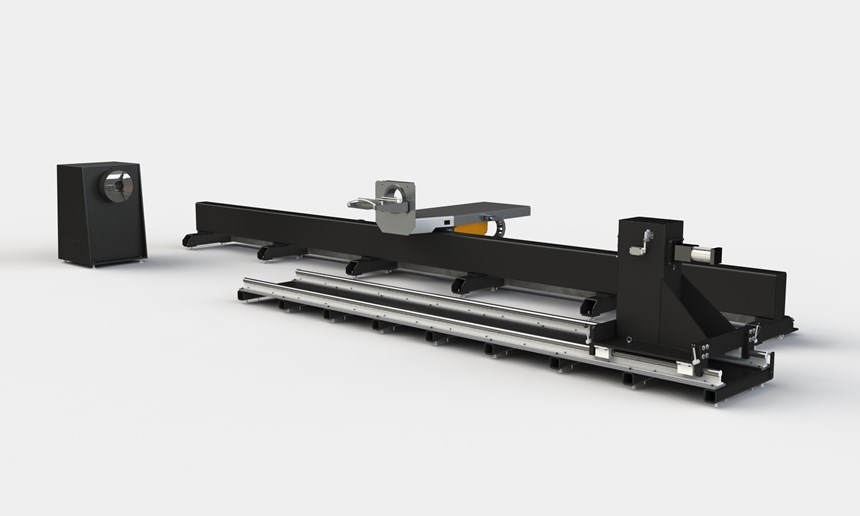

The CXG, for winding compressed natural gas (CNG) or compress hydrogen gas (CHG) tanks, is designed for high-volume manufacturing and features a dual-drive carriage. It has a maximum mandrel weight of 454 kg, maximum mandrel length of 5000 mm, mandrel diameter of 25-406 mm, three to five spindles and four axes.

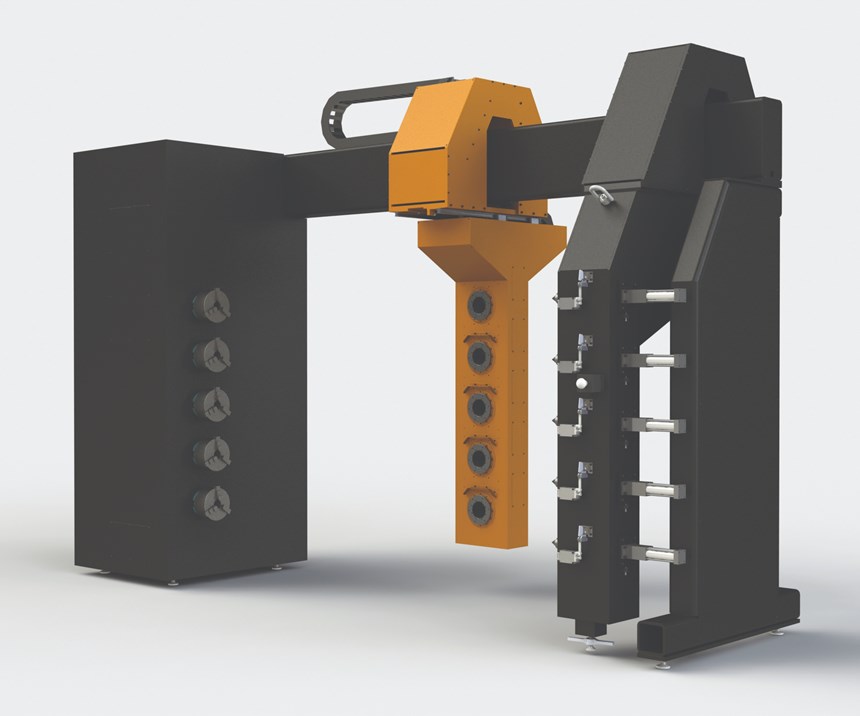

The SL and SL+ are large-format winders designed for aerospace and oil and gas applications. The offer a maximum mandrel weight of more than 2268 kg, maximum mandrel length of more than 5000 mm, mandrel diameter of 25-2032 mm, one spindle and two to six axes.

Click here to download a PDF of the entire line of Entec filament winders.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;maxWidth=300;quality=90)