Five-axis CNC machining center delivers on versatile materials processing needs

CAMX 2023: Biesse America highlights the Rover Plast A FT, capable of adaptable milling and cutting operations for plastics and composite materials with high precision and a quality finish.

Share

Read Next

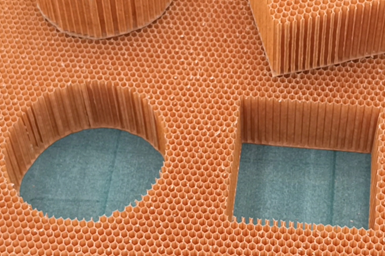

Visit Biesse America (Charlotte, N.C., U.S.) for a demonstration of the Rover Plast A FT, a three-axis with four-axis prearrangement machining center for milling and cutting plastic and composite materials typically used for the production of technical articles and in the aerospace, motor, construction and wind energy sectors. Precision and high finish quality are some of its key features.

The Rover Plast A FT is said to be the ideal solution for machining materials of different formats, sizes, thicknesses and densities. The highly rigid and well-balanced structure is designed to withstand notable machining strain and ensure high levels of precision.

The CNC machine can be equipped with cutting units with blades of different types. The tangential/oscillating blade, combined with a video camera for optical recognition of the print markers, gives the machine greater versatility to adapt to every market need.

The Rover Plast A FT is equipped with B_Solid, the company’s 3D CAD/CAM software application that supports the performance of any machining operation thanks to vertical modules designed for specific manufacturing processes.

From preventative maintenance to predictive maintenance, Biesse America’s goal is to not only provide quality technology but industry-leading after sales support. Sophia, Biesse’s Internet of Things (IoT) and Parts platform, is said to bring these machines to the next level. CAMX attendees will be able to learn how the cyber-physical assistance system can delivery greater value, providing a comprehensive overview of machine performance features with remote diagnostics, continuously updated statistics and full integration with the company’s new Parts portal where customers can purchase parts, check availability and track purchases 24/7.

Related Content

-

CAMX 2023 Attendee Survey

CAMX – The Composites and Advanced Materials Expo is right around the corner, and we want to better understand your hopes and expectations heading into the show. CompositesWorld asks you to answer one of the five questions in the survey below. Responses will remain anonymous, and some may be published in the CAMX Show Daily, which is distributed at the show. The survey will take less than 5 minutes to complete.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.

.jpg;maxWidth=300;quality=90)