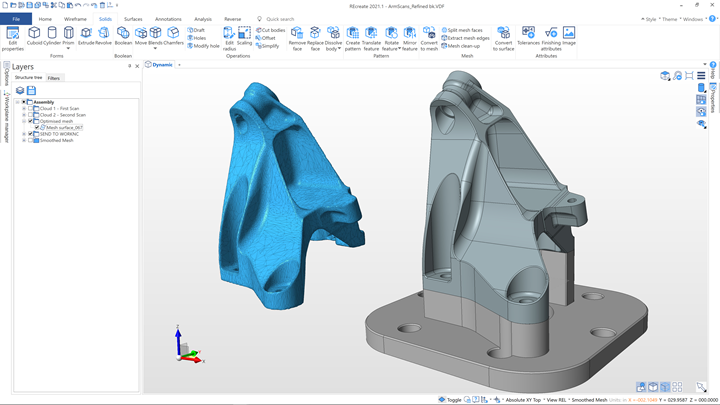

Hexagon REcreate reverse engineering software removes workflow complexity

Simplified reverse engineering processes provides a single working environment from scan to manufacturable CAD model.

Photo Credit: Hexagon

Hexagon’s Manufacturing Intelligence division (North Kingstown, R.I., U.S.) has unveiled REcreate, a powerful and flexible new software solution designed to make it easier and faster to reverse engineer parts from metrology scan to manufacturable model via more streamlined digital workflows.

Designed to remove complexity, REcreate is said to provide a single working environment from scan to manufacturable CAD model. Users can prepare CAD models and drawings from any point cloud data. The software’s fully featured CAD tool suite enables users to create complete and manufacturable CAD models as well as 2D engineering drawings. REcreate’s analysis tools also allows manufacturing professionals to interrogate those 3D models and validate whether they are manufacturable before exporting as CAD or STL for computer aided manufacturing (CAM) or additive manufacturing (AM) processes.

While designed to be interoperable and slot into a customer’s existing processes, Hexagon says the solution offers additional benefits to customers that use other Hexagon technologies in their workflow. Sites that use Hexagon’s portable arms for inspection can reduce training needs by allowing any operator to read inspection data directly from the device to reverse engineer. REcreate is also rigorously tested with Hexagon’s production software tools that are used to plan, optimize and program machining processes.