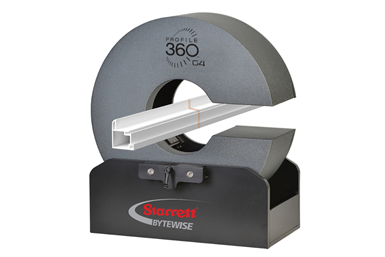

Starrett-Bytewise highlights Profile360 in-line laser measurement system

Now available with a 30% discount, the real-time system continuously monitors key profile dimensions in complex shapes in a variety of materials to assure quality and avoid defects.

Starrett-Bytewise (Columbia, Ga., U.S.) a manufacturer of laser-based measurement systems and a division of The L.S. Starrett Co. (Athol, Mass., U.S.), has announced a year-end promotion for the Profile360 in-line, real-time laser measurement system with 30-100-mm field-of view.

The Profile360 continuously monitors key profile dimensions in complex shapes — such as rubber, plastic, ceramic, fiber-reinforced composites, wood-plastic composite extrusions and roll-formed metal profiles — to assure quality and avoid the high cost of defects. The system acquires thousands of data points around the profile and matches them to a CAD template, where key measurement parameters such as width, thickness, gap, radius and angle are extracted. Measurement parameters are compared to allowable control limits and displayed on the operator's terminal with a pass/caution/ fail status indicator. Profile360 runs at rates up to 20 profiles per second. The system is available in standard sizes and can be custom-built for almost any size and shape.

A 23% discount is available on Profile360 orders. A 30% discount is available on Profile360 orders that include a Profile360-G3 trade-in. Year-end discounts for other Starrett-Bytewise products are also available. To qualify for the discounts, orders must be received by Dec. 31, 2023.

.jpg;maxWidth=300;quality=90)