The European Alliance for SMC BMC launches design guide series for SMC, BMC composites

Thought of as bridging the gap between steel and thermoplastics, SMC and BMC material applications continue to grow. This design guide series addresses uses, questions and tips.

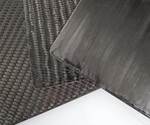

Photo Credit: The European Alliance for SMC BMC

As sheet molding compounds (SMC) and bulk molding compounds (BMC) are being increasingly used in a broad range of end-use applications and markets, the European Alliance for SMC BMC, a European association operating under the umbrella of EuCIA (Brussels, Belgium), is launching a series of design guides that explain to designers how these versatile materials can be used, and manufactured in larger production series.

The design guides will reportedly address a number of frequently asked questions concerning design and manufacture of SMC/BMC components and offer some practical tips to ensure their successful deployment. According to the European Alliance for SMC BMC, the first design guide will discuss the design process, potential design pitfalls, tool design considerations, the cost of an SMC mould and pose the question of whether to source production in-house or externally.

Copies can be found online here.

Related Content

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

Mar-Bal expands SMC expertise through AltraSet materials division

The BMC company aims to fill the SMC market gap for those seeking optimal, low-volume demand with custom formulation and high material value.

-

SMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.