SMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.

Share

Read Next

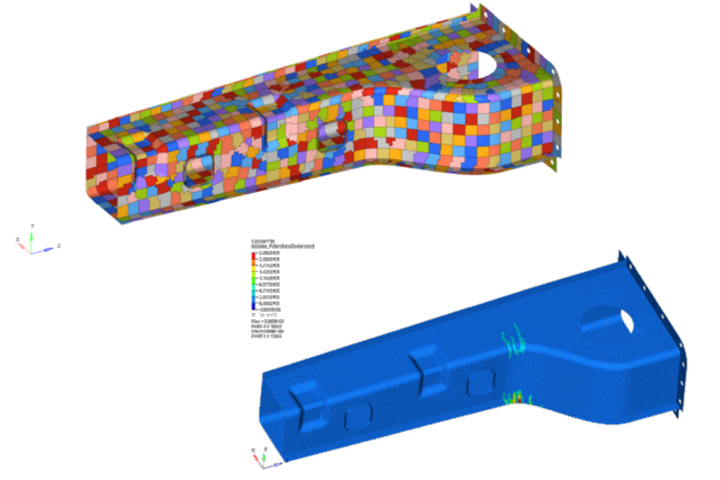

The top left image depicts discretizing a model into representative laminate volume elements (RLVEs) using a customization of Hypermesh, where each RLVE consists of a distinctive laminate layup. Running multiple instances of this model (top left) generates a population of results. The bottom right image depicts a cumulative damage plot, where failed elements are accumulated and plotted to highlight where the design may be weak and requires reinforcing or added thickness. Photo Credit: HRC/Engenuity

Failure in Random Material Architectures (FiRMA) is Engenuity’s (West Sussex, U.K.) distinctive analysis approach for sheet molding compound (SMC). It enables designers to optimize SMC structures through an accurate predictive technique that calculates the weakest and strongest components expected in a batch.

Theoretically, the material strength in SMC at any particular location can range from matrix strength (poor) to unidirectional fiber strength (good) — or anywhere in between. According to Engenuity, one material property, applied everywhere in the model immediately compromises the simulation quality. FiRMA accounts for this range in material properties by preprocessing the model and coupling testing with simulations to arrive at a modeling method that accurately reflects the material at all scales.

FiRMA determines the range of performances a population of parts will exhibit while also providing information across the population about where the material starts to degrade. The approach has been developed to be compatible with other modeling practices — adding reinforcing tapes or coupling with crash simulations such as Engenuity’s specialist composite crash add-on, CZone.

Currently, FiRMA assumes a random fiber distribution across the part, which is suitable for many applications. However, a research project is currently underway to apply this technique to more complex structures. Called FEA-SMC and funded by the ATI through the NATEP program, Engenuity is working with Spirit Aerosystems, Creative Composites, WMG and Simutence to upgrade FiRMA. The new version, FiRMA Flow, will include flow effects present in the material during compression molding. It will enable biasing of the fiber orientation so that a non-random distribution derived from a process simulation can be used for the structural simulation.

Overall, FiRMA allows SMC to be used in more structural and semi-structural applications without the need for prototyping, gives more confidence to designs, speeds up development time and reduces development cost.

Related Content

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.