Hi-Temp Resins

Composites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

WatchFlexible, induction-based heating for thermoplastic composite part repair

Spinning off from a German Aerospace Center (DLR) research project, msquare GmbH’s technology aims to innovate and enable repair for high-temperature thermoplastics.

Read MoreCAMX 2022 exhibit preview: Renegade Materials Corp.

Renegade Materials is promoting its high-performance prepreg, RTM resin and adhesive products for use in demanding aerospace applications.

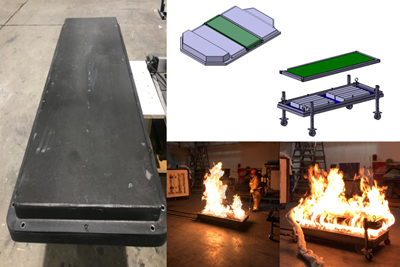

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

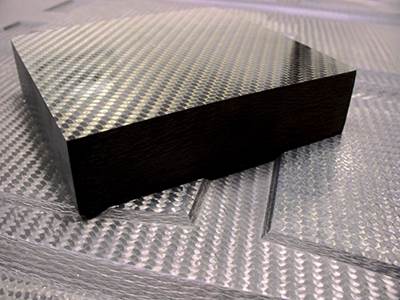

Read MoreSuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

WatchPlant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

WatchSicomin supports large-scale interior project for Museum of the Future

Sicomin aided Dubai-based Advanced Fiberglass Industries with its bio-based gelcoats and resins to meet challenging structural and fire safety specifications defined for more than 200 double-curved entrance lobby panels.

Read MoreMulti-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

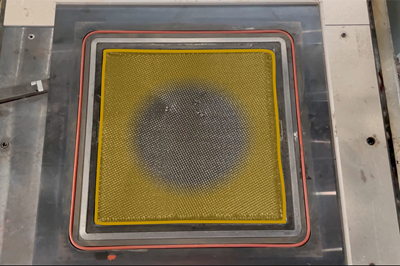

WatchNexam Chemical, the NCC develop solution for manufacturing high-temperature composites

Nexam Chemical’s Neximid high-temperature resin system can operate at temperatures up to 400°C, expanding the boundaries of composites into more demanding applications that weren’t previously possible.

Watch