Prepregs

Developing next-generation composites talent

The M.C. Gill Composites Center at the University of Southern California has steadily grown to become one of the industry’s educational and R&D stalwarts.

WatchKordsa fast-cure prepreg targets automotive mass production

Kordsa’s fast press curable resin boasts an enhanced visual quality, enabling the possibility of prepreg use in automotive mass production.

Read MoreComposites One to distribute Solvay process materials and tooling products

Solvay has appointed Composites One as a new North America distributor for its process materials and tooling product lines.

Read MoreDark Matter Composites announces 2019 course schedule

Consultancy and composites design and prototyping service provider offers composite training courses.

Read MoreMikrosam delivers multi-material AFP system to Brandenburg University of Technology

The 8-axis robotic AFP machine is reportedly capable of automated and precise placement of thermoplastic fibers, thermoset prepregs and dry-fiber material.

Read MoreFiber Patch Placement wins JEC Innovation Award in Seoul

Featuring a multi material feeding unit, Cevotec’s SAMBA Multi automates the time- and cost-intensive multi-material lay-up of aerospace sandwich components.

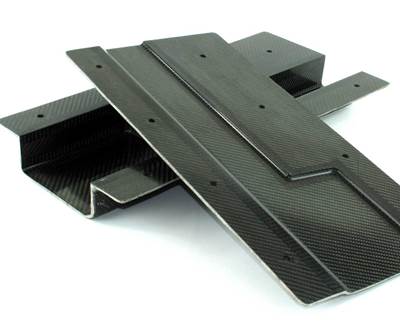

Read MoreComposites Evolution develops hybrid tooling prepregs

Composites Evolution has developed a new tooling prepreg system based on a hybrid combination of carbon fiber and flax fiber reinforcements.

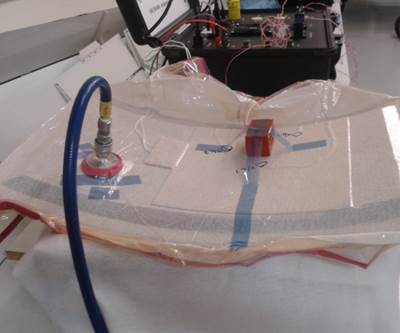

Read MoreMeasuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

Read MorePark Aerospace's epoxy, cyanate ester resins target advanced radome applications

Park Electromechanical Corp. has introduced RadarWave, a new family of prepreg materials developed for the fabrication of advanced radome systems, principally for aerospace and defense applications.

Read MoreAirtech launches new carbon fiber prepregs

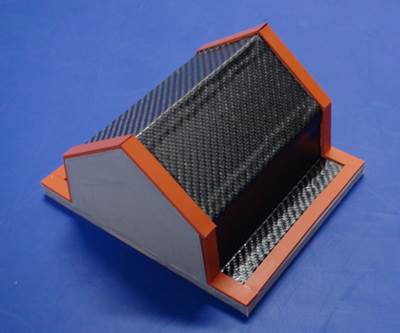

The company’s LTC3 prepregs are said to offer a low temperature cure and high temperature use after post cure, and allow the use of lower cost master model materials.

Read More

.jpg;maxWidth=300;quality=90)