SAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.Nondestructive inspection

Nondestructive testing solutions

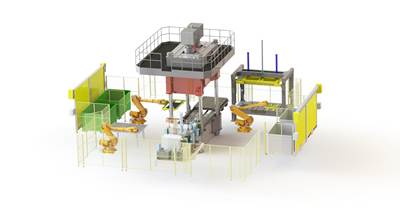

In 2013, Areva (Lynchburg, Va.) made its first appearance as a SAMPE exhibitor. As a developer of advanced nondestructive inspection solutions, primarily using ultrasound, the company provides solutions for inspection of finished composite parts, including a single-robot system for inspection of complex composite structures and a dual-robot system for honeycomb structures. Flexible linear gantry inspection systems also are available for flat or curved composite panels, skins and stringer components. Areva’s customers include Airbus (Toulouse, France) and The Boeing Co. (Seattle, Wash.).

Bagging films and more

Airtech International Inc. (Huntington Beach, Calif.) highlighted several products at the SAMPE 2013 show, including Toolwright 5, an extruded fluoropolymer film coated with silicone pressure-sensitive adhesive. The yellow color is highly visible on most substrates, and the film offers high elongation and tensile strength. Also on display was Securlon V-45, an economical bagging film for commercial autoclave processing. It is ideally suited for high-performance automotive applications, where high-temperature/high-pressure cure is needed, and for transportation interiors that use phenolic prepregs.

Fabrication management system

Assembly Guidance Systems’ (Chelmsford, Mass.) D3 fabrication management system made its debut at SAMPE 2013. The system, designed to reduce discrete hardware, data entry and data integration requirements, is said to extend the company’s LASERGUIDE capabilities by offering fabricators a single point of contact for all fabrication processes. It already has been adopted by major aerospace and automotive companies to perform and manage laser-guided kitting, layup, ply verification, foreign object debris prevention and correction and final documentation. The D3 name signifies the three primary capabilities that it integrates into the LASERGUIDE platform: data collection; defect prevention and correction; and documentation. The data collection features include importation of design data and capture of ply material type, orientation, batch and out time, debulk cycle and other pertinent information. The correct fiber orientation also is verified and documented. Defect prevention is integrated directly into the fabrication process in real time by the system. As a result, D3 enables defect correction at the earliest point in the production cycle so resolution occurs at the lowest cost and with the greatest time efficiency possible. Finally, D3 documentation gives fabricators and end-users searchable, traceable, controlled and usable information about each individual component, enabling verification that acceptable tolerances have been achieved. Discussions are also underway, Assembly Guidance reports, with companies that would like to interface quality data in the cloud. Assembly Guidance officials noted that capturing detailed data at the point of fabrication and providing that data to the customer enables a more thorough understanding of issues like manufacturability and quality control.

Snap-cure epoxies and phenolics

At SAMPE 2013, Barrday Composite Solutions (Millbury, Mass., and Cambridge, Ontario, Canada) showed its range of advanced solutions for aerospace, defense, transportation, energy and protective markets. The company says its snap-cure epoxies — including EP202, available in fabric, unidirectional tape and film adhesive forms — are in demand for automotive applications. Also on exhibit was Barrday’s low-heat release phenolic snap-cure prepregs — including LC296 in fabric form, designed for aircraft interiors — and its advanced thermoplastic prepregs (fabric and unidirectional). The phenolic prepreg’s low-heat release properties, less than 30/30 as measured by the Ohio State University (OSU) test, means that higher-end decorative materials can be used for aircraft interior panels. The thermoplastic prepregs are targeted to a variety of high-performance applications in the aerospace/defense, oil and gas and industrial markets.

Wetting additives

At the 2013 show, first-time SAMPE exhibitor, BYK USA (Wesel, Germany, and Wallingford, Conn.), featured its wetting additives for carbon and natural fibers. In addition to a sheet molding compound (SMC) line that the company uses to test and develop new additives, BYK has recently invested in building a new laboratory at its headquarters in Wesel and installing a computer-controlled, 160-ton compression molding press for testing and product development.

RTM solutions

During its first time as a SAMPE 2013 exhibitor, Callaway Carbon (Santa Ana, Calif.) touted its design, engineering and production services for carbon fiber composites. Callaway introduced its new one-step, integrated resin transfer molding (RTM) process that incorporates fasteners, thus reducing postprocessing. Sensors in the computerized RTM system capture and display the basic operating parameters of temperature, pressure and flow rate during the molding procedure. This capability reportedly results in the ability to produce repeatable parts with consistent weight, along with automatic production of complete documentation.

Midrange prepreg system

Century Design Inc. (CDI, San Diego, Calif.), a supplier of prepregging machinery for high- to low-volume applications, introduced at SAMPE 2013 the CD6018 Series, a midrange machine designed for applications that require low to medium volumes of fabric. Features of the machine include widths of 40 to 60 inches (1,016 to 1,524 mm), a maximum speed of 60 ft/min (18.3m/min), automated system setup and data analysis, high-precision compaction roll set and data collection and monitoring of key processing parameters. Filming is provided by an applicator roll, and the machine can accommodate a mixed viscosity range of 1,000 to 300,000 cps. The paper substrate is two-sided silicone that is differentially coated. The machine is 30 ft long by 9 ft wide by 10 ft high (9.1m by 2.7m by 3m).

Faster failure analyses

Collier Research Corp. (Newport News, Va.) released at SAMPE 2013 Version 6.4.50 of its composites optimization software, HyperSizer. According to company president Craig Collier, the latest version has significant new capabilities. For example, the improved analysis engine provides all analytical and numerical failure analyses 200 to 400 percent faster than the previous version, and laminate sequencing operations are also much faster. The FEA import interface has been rewritten, primarily to support large FEM and FEA results data files, and there is improved support for CATIA CPD (from Dassault Systèmess (Vélizy-Villacoublay, France). Collier says the new version can optimize 1,000 times faster, enabling rapid production of mature designs. Users can reportedly perform very accurate structural sixing for weight and cost estimation based on producibility tradeoffs for vehicle-level system design trade studies. There also are improvements in laminate sequencing and a new user interface to define FEA constraints.

Custom patterned weaves

At SAMPE 2013, Composite Fabrics of America (CFA, Taylorsville, N.C.), a custom weaver of carbon, glass and aramid materials, introduced Textral, a line of custom-patterned carbon fiber fabrics that is reportedly exclusive to CFA. Trading on the appeal of “exposed” (clearcoated) carbon fiber weaves in molded composites, CFA offers a variety of patterns in both 3K and 12K constructions that go beyond the standard plain or twill weave. CFA says it can create a custom weave that will be exclusive to the customer and that it can incorporate company logos or icons into the weave to bring a a unique flare and appeal to the customer’s products. The company’s markets include aerospace, automotive, sports, marine, military and wind energy. CFA is a subsidiary of Schneider Mills in Taylorsville, a weaving business that was established in 1916.

Spread-tow materials

Composites One (Arlington Heights, Ill.) announced at SAMPE 2013 a new addition to its product card: TeXtreme spread-tow reinforcements manufactured by Oxeon (Borås, Sweden). Already in stock are some commonly used TeXtreme variants, and the Composites One staff has undergone special training by Oxeon to better identify the most suitable product for specific application needs. TeXtreme spread-tow materials are already being used in NASCAR, Formula 1, America’s Cup, aerospace and sporting goods.

Ambient-cure epoxy resin system

At SAMPE 2013, CRG (Cornerstone Research Group Inc.) (Dayton, Ohio) displayed, and presented a technical paper about, its No Oven, No Autoclave (NONA) resin system. The proprietary, untoughened two-part epoxy has a pot life up to two hours at room temperature, without added heat, and requires no postcure, says the company. Very thick sections are possible, and tests of tools made with NONA in a vacuum-assisted resin infusion process showed a Tg of about 400°F/204°C, reportedly comparable to a prepreg/autoclave-cured prepreg. Target applications for this out-of-autoclave technology include tooling, very large parts (e.g., wind blades or launch vehicles), civil infrastructure and applications in which the on-site manufacture of large structures is the only feasible option.

Automated, wireless out-time monitoring

First-time exhibitor DeltaTRAK Inc. (Pleasanton, Calif.) introduced at SAMPE 2013 its newest automated Out-Time Calculation solution, called FlashLink RF Wireless. The system is reportedly the result of the company’s expertise in “cold chain management,” that is, the ability to track and document temperature and out-time data during the storage and transportation of prepreg and other time- and temperature-sensitive (TATS) materials. As TATS materials, prepregs must be monitored to ensure acceptable material performance. The Flashlink RF (radio frequency) Wireless solution is applicable to materials manufactured for use in the aerospace, automotive, sporting goods and wind energy industries, including not only prepreg but carbon fiber, fiberglass, Kevlar, potting materials, sealants and other TATS materials. DeltaTRAK notes that manual tracking of temperatures is labor- and time-intensive, prone to human error and lacks traceability. FlashLink RF Wireless continuously and automatically collects information in real time, with data visible on a PC monitor, and stores the information for data reporting, and features an alarm system as well. DeltaTRAK claims this gives management the product visibility and traceability it needs to meet internal and external quality control and regulatory guidelines.

Process control oven for composites

At SAMPE 2013, Despatch - ITW EAE (Minneapolis, Minn.) presented its new Focal Point process control system for composite curing. The PC-based system was developed in-house and is reportedly easy to navigate, yet it controls the complete oven-cure process and provides traceability and validation of part quality in spreadsheet or database format. Despatch says the powerful system can be adjusted and customized to fit their customers’ applications, and it is similar to process-control systems typically installed on autoclaves. Remote modules, such as part thermocouples and vacuum subsystems, can be added to the platform and can communicate with the oven’s PLC (programmable logic controller) through an Ethernet connection.

Large-format CNC router

Ferry Industries Inc.’s (Stow, Ohio) SAMPE 2013 booth was dominated by a large Quintax Machining Center, the 5512 Speedmill E5, a 5-axis CNC router for a range of nonferrous materials. The machine has a work envelope of 12 ft by 5 ft by 4 ft (3.7m by 1.5m by 1.23m), with the 4-ft/1.23m dimension in the z-axis; larger sizes are available. The modular construction allows for simple installation, yet the fully enclosed unit is reportedly rigid enough for the most demanding machining applications. Further, the enclosure offers noise and dust control. Many options are available, including dual work-zone packages and mist lubrication systems.

Lost-core RTM

Fiber Dynamics Inc. (Wichita, Kan.) featured at SAMPE 2013 its Lost Core RTM Process for producing hollow-cavity components, along with its one-shot, integrated resin transfer molding (RTM) and vacuum-assisted RTM (VARTM) structures. The company uses its Lost Core RTM process to mold a hollow landing gear strut for General Atomics’ Predator B UAV, which is made of unidirectional and braided S2-glass and has titanium and aluminum fittings secondarily bonded to the ends. The part is a so-called sprung strut that depends on the spring action of the strut to cushion the landing. A prototype for another landing gear strut for an unnamed UAV also was developed using Lost Core RTM; it was made with IM7 unidirectional carbon fabric supplied by Hexcel (Stamford, Conn.). This landing gear differes form the sprung strut, because it uses a shock absorber to cushion the landing. Titanium plates are interleaved in areas of high bearing and point loads to provide additional stiffness and load-bearing capability.

Patented thermoplastic prepregs

Fibrtec Inc. (Atlanta, Texas) exhibited its patented thermoplastic prepregs, available in a wide variety of fiber types and resins that reportedly can be braided, woven and converted into custom preforms with tailored fiber placement. The company recently acquired equipment from LayStitch Technologies (Highland, Mich.) that allows its materials to be assembled into complex, ready-to-mold preforms. Also on display was the company’s proprietary sh-MCNTs (short, multiwall carbon nanotubes), trademarked Ros-1, a functional additive that is reportedly more stable and easier to disperse in solutions or resin, compared to other carbon nanotube products that can tangle or agglomerate. Applications for the Ros-1 nanotubes, which are licensed from Rosseter Holdings Ltd. (Limassol, Cyprus), include thermally and electrically conductive resins and abrasion-resistant coatings.

Tensioners for filament winding

Helman Composite Machinery (Taneytown, Md.), a division of Taneytown-based MasterWorks, is new to composites and to the SAMPE. Show. Originally a supplier of filament winding tensioning systems, Helman Engineering was purchased by MasterWorks in 2010. At the 2013 show, Helman exhibited its capabilities in not only tensioners, but also complete filament winding work cells, from fiber and resin handling to winding machines to curing ovens, as well as part and process design, particularly for high-pressure compressed natural gas (CNG) tanks. On display were Helman tensioners that incorporate unlimited takeup and maintain even fiber tension, as well as filament winding payout arms and rings that help maintain proper fiber bandwidth and consistency to ensure a quality product, no matter the size and type of filament winder.

UD tape for dry automated tape laying

Hexcel (Stamford, Conn.) emphasized at SAMPE its new HiTape product, a dry unidirectional (UD) tape designed for use in automated tape laying (ATL) applications and then molded via infusion. Hexcel says parts produced with HiTape reinforcements and HexFlow infusion resins can be up to 30 mm/1.2 inches thick with a 58 to 60 percent fiber volume fraction. The tape’s mechanical properties reportedly are as good as those found in parts made with the latest generation of primary structure prepregs. The company says HiTape has been used to “great effect” by Aerocomposit (Moscow, Russia) for wing prototype components.

Adhesive testing system

Hysitron (Minneapolis, Minn.), a pioneer in developing nanomechanical test instruments, introduced at SAMPE 2013 its new technique for adhesive testing and quantification of bond strength using an indentation “push-in” test and nanoiindentation. The procedure uses compression force and imaging to determine a composite’s mechanical properties and delamination force-displacement curves.

Manufacturing simulation

Magestic Systems (Westwood, N.J.) introduced SAMPE 2013 showgoers to its TruPLAN software, which is designed to allow composite design engineers to simulate manufacturability of composite parts and choose the best manufacturing process. The company cited several advantages for users. Among them are material modeling to highlight layup defects, such as bridging, wrinkling and pull-up; and material consolidation analysis through modeling roller deformation and the impact of the layup process. Magestic’s technical partners include Dassault Aviation (Paris, France), The Boeing Co. (Chicago, Ill.) and Airbus (Toulouse, France).

Heating/chilling control systems

At the 2013 show, first-time SAMPE exhibitor Mokon (Buffalo, N.Y.) showed its range of water- and oil-based temperature control systems for process heating and chilling. Intended for composite mold heating and cooling, and other material production applications, the water units can produce temperatures up to 380°F/193°C; the oil units can reach 700°F/371°C. A wide range of pump flow rates are available, in single or multizone configurations, designed for a variety of temperature requirements.

Portable inspection system

Exhibiting at SAMPE 2013, MoviTHERM (Irvine, Calif.) featured its portable nondestructive testing (NDT) system, C-CheckIR, for onsite inspection of large products, such as aircraft wing skins and wind turbine blades. The inspection head is mounted on a lightweight support frame that is equipped with vacuum suction feet capable of holding firm during suspended inspection — the underside of a wing, for example. In cases where in-flight damage to a wing from a bird strike or other impact isnot visible, the system can be brought to the site for inspection, either to confirm the plane’s soundness for flight or to show a need for repair before it is returned to service (see photo).

Thermoplastic composite sheet stock

A SAMPE 2013 first-timer, Olimunllum America LLC (Santa Barbara, Calif.), showed its consolidated, heavy-duty thermoplastic composite tape (carbon fiber/modified polyetheretherketone) sheet, plates and profiles. From the Catalan word meaning “light in the lamp,” a synonym for a great idea, the semifinished carbon composite offers impact strength and high fatigue resistance with a continuous service temperature up to 250°C/482°F. The material is intended for thermoforming or compression molding and can also be machined and cut to shape, like a metallic component, says the company. Olimunllum’s material has been used extensively to date for parts in racing motorcycles.

FST-compliant thermoplastic composites for aircraft interiors

Polystrand’s (Englewood, Colo.) TechStrand business unit introduced at SAMPE 2013 its AeroStrand material, which combines continuous, high-strength fiber with an engineering thermoplastic. Designed for use in aircraft interiors and characterized by Polystrand as competitive with phenolics, AeroStrand is a flame-retardant, self-extinguishing, low-smoke, low-heat-release, low-toxicity and cost-efficient material that is said to exhibit good chemical and corrosion resistance and provide good UV stability. Polystrand provided data from AccuFleet Testing Services (Houston, Texas) showing that AeroStrand, comprised of 0°/90° unidirectional E-glass and a fluoropolymer resin, passed the 60-second vertical burn test, the 12-second vertical burn test and the 2.5-inch PM horizontal burn test. It has a flex strength of 45,600 psi, a flex modulus of 3.3 million psi and fiber content by weight of 48 percent.

Epoxy resin systems

Exhibiting for the first time at SAMPE 2013 was Sicomin Epoxy Systems (Marseille, France), which has had a presence in Europe for many years but is now serving the North American market via distributor Core Composites (Bristol, R.I.). Sicomin’s epoxies are designed for use in wind, marine, energy, transportation and aerospace applications. Applicable processes include laminating, infusion, prepregging and epoxy foaming. For aerospace, the company is focusing on interior applications; its products meet Federal Aviation Regulations (FAR) Part 25-853 and Heat Release Rate (HRR) requirements. The HRR-compliant material is a prepreg that the company says is still in development, but it should be ready for commercialization later in 2013.

Plasma surface treatment

Surfx Technologies LLC (Redondo Beach, Calif.) featured at SAMPE 2013 its treatments using plasma gas as an alternative to manual surface preparation. The company’s Standalone Plasma Machine, a turnkey system, integrates its trademarked Atomflo plasma solution into a multiaxis application system with gas handling and a unified human/machine interface for surface preparation before bonding, cutting or painting. The machine offers helium and argon plasmas, with oxygen, nitrogen, hydrogen or additional secondary gases for treatment of composites, ceramics, metals and plastics.

Tooling prepregs

TenCate Advanced Composites (Morgan Hill, Calif.) showed several innovations and new products, including a new line of tooling prepregs, in collaboration with 3M Performance Materials Div. (St. Paul, Minn.). 3M Fortified Tooling Prepreg 140 TC24-Si, based on 3M’s proprietary nanosilica-filled resin, results in a tool with greater hardness and durability, lower coefficient of thermal expansion (CTE), improved fracture toughness and less springback. TenCate’s Cetex TC1220 is the company’s newest polyetheretherketone (PEEK)-based unitape; it features extreme compression after impact (CAI) mechanical performance, says the company. Also on display was a Reebok ZigCarbon running shoe that features a wild zigzag sole and a TenCate Cetex carbon twill/polymethyl methacrylate (PMMA) outsole that is visible through the zigzag material. The shoe has reportedly received good reviews from runners since its release.

Fiber-reinforced aluminum

Triton Systems Inc. (Chelmsford, Mass.) and Specialty Materials Inc. (Lowell, Mass.) announced at SAMPE 2013 that they have agreed to work together to scale up and manufacture fiber-reinforced aluminum (FRA). The material, developed by Triton, features randomly oriented alumina-silicate fiber in fiber-volume fractions of about 26 percent, making it one-third the weight of steel. It also is said to have three times the elevated temperature strength of conventional aluminum alloys. The material is provided in billet form and can be machined with carbide or diamond-coated machine tools. Potential applications include bearing cases, heat exchangers, actuator housings, bushings and wear inserts, among others. Specialty Materials officials said the FRA is being tested in a bearing case application with two rotorcraft manufacturers.

Low-emission autoclaves

Walton Process Technologies Inc. (WPT, Mansfield, Texas) highlighted new developments in its autoclave technology. WPT Green Systems incorporates low and ultralow nitrous oxide (NOx) gas burner systems, with nozzle mixing, precision air-to-gas control valves and an intelligent ratio controller to reduce NOx emissions (measured as parts per million) by up to 85 percent and carbon monoxide emissions by 99 percent. Green Systems also reintroduces exhaust air back into the heating system to reduce the amount of energy required to heat the ambient air inside the autoclave, which reduces fuel consumption of the gas burner by an average of 25 percent during ramp up and 70 percent during the soak for each cure cycle, says the company. Also in development is a new hybrid burner system that incorporates both gas-fired and electric thermal process equipment.

WichiTech Industries Inc. (Baltimore, Md.) announced at the show that it has a new distribution partner in Europe. Aerotecs NV (Lummen, Belgium) will sell WichiTech’s Hot Bonder Composite Repair systems, blankets and all accessories, says the company. Aerotecs will also provide any warranty and nonwarranty repair work so products will no longer have to be shipped back to the U.S.

Low-odor, no-HAP release coats

Zyvax (Ellijay, Ga.) reported that its Flex-Z line of variable-release slipcoats is now being used by The Boeing Co. (Chicago, Ill.) for production of 787 Dreamliner parts. Flex-Z is an array of six resin polymer products on a common chemical platform that reportedly contain no hazardous air pollutants (HAPs) and are thermally stable up to 900°F/480°C. The benefits for advanced composites include negligible odor, easy application, easier layup and great postpaint or bond properties. Flex-Z does not need to be wiped off, which reduces labor and cloth usage by more than 50 percent.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreBusch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePlataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MoreRead Next

JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

Read MoreSAMPE Long Beach 2013 review

The Society for the Advancement of Material and Process Engineering’s (SAMPE, Covina, Calif.) spring conference and exhibition is the organization’s largest event every year, and the 2013 edition, held May 6-9 in Long Beach, Calif., was no exception.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More