DarkAero 1 is a long-range, high-speed, two-person, experimental all-composite airplane. The entire airframe, made mostly from carbon fiber/epoxy, weighs about 200 pounds. Photo Credit: DarkAero

General aviation is a broad term that encompasses all civil aviation that is not large-scale, regularly scheduled freight and passenger operations. This means anything from ultralights to multi-engine turboprops and turbofan jet planes. For the purposes of this article, we’ll primarily focus on piston-powered, fixed-wing aircraft typically used for business or pleasure travel. In the U.S., that’s about 175,000 planes flying into roughly 5,000 public airports, of which only ~10% have regularly scheduled commercial flights.

General aviation, both certified and experimental, has embraced fiber-reinforced composites for more than 60 years. During the late 1950s, Piper Aircraft (Vero Beach, Fla., U.S.) built an all-fiberglass prototype, the PA-29 Papoose. In the 1960s, sailplane (glider) manufacturers, always looking to reduce weight and improve lift-over-drag ratios, began to extensively use fiberglass. After an eight-year certification process, in 1969 the Windecker Eagle I became the first U.S. Federal Aviation Administration (FAA) certified, all-composite-powered airplane with its nonwoven fiberglass “Fibaloy” and foam construction.

Composite experimental (homebuilt or kit) general aviation aircraft really took off in the early 1970s with Burt Rutan’s very popular VariEze (and derivations like the Long-EZ) canard pusher aircraft. One of Rutan’s innovations was to use sandwich foam as the “tool” which allowed for “moldless” fabrication of composites.

In the 1990s, general aviation began to use carbon fiber composites and slowly worked out of a major slump from the 1980s. Major general aviation manufacturers such as Cirrus Aircraft and Diamond Aircraft Industries introduced still-popular lines of single-engine certified planes. Experimental planes soon moved to ever-increasing carbon fiber content, and the new Light Sport Aircraft (LSA) category brought in more opportunities for composites.

Categories of general aviation aircraft

The three main categories of general aviation fixed-wing planes (Certified, Experimental and LSA) all bring with them various levels of challenges for composites.

Certified planes are government-approved (by the FAA in the U.S.) and require years of development and testing to prove out the design and manufacturing processes. Experimental planes are majority-built by individuals from plans or kits, and while there is some governmental oversight, it is more relaxed and thus open to more innovation.

LSA is something of a bridge between the other two categories. These planes are not as rigorously certified (using industry-consensus standards instead of government mandates) and are therefore open to more innovation but generally are manufacturer-built with more process control than Experimental aircraft. LSA designs are also limited in aircraft weight, number of occupants and speed, though new rules are being considered to expand those limits and possibly add a new category, Light Personal Aircraft.

Experimental aircraft M&P

Composite materials and processing vary across general aviation categories. But broadly speaking, the emphasis is on low cost and moderate performance with standard, untoughened epoxies and E-glass fiber reinforcement being very common (though standard modulus carbon fiber is becoming more widespread).

For the Experimental category, basic wet layup processing has historically dominated, either for fiberglass or carbon fiber. Low-viscosity, two-part room temperature curing epoxy is hand-mixed in precise ratios by weight and manually spread onto dry cloth, then cut to shape and laid on simple tooling or shaped foam, which acts as a flyaway tool for sandwich structures.

In recent years, infusion processing such as vacuum-assisted resin transfer molding (VARTM) has become more popular. Dry fabrics include 7781 fiberglass and/or 2x2 carbon twill (hybrid layups with mostly fiberglass and limited amounts of carbon fiber are common) which are then laid up in a mold with tackifier and bagged; the low-viscosity, two-part epoxy is pulled into the layup with vacuum. Planes like the Arion Lightning or DarkAero’s DarkAero 1 are taking advantage of the less messy, better quality, higher fiber volume parts that infusion can provide.

Lantor Soric infusible core is used on the fiberglass fairing just aft of the canopy on the DarkAero 1. Photo Credit: DarkAero

DarkAero (Madison, Wis., U.S.), formed by a team of three engineer brothers, saw carbon fiber as being the key to achieving their aggressive performance goals (275 mile per hour cruise for more than six hours) through improved aerodynamic shapes with optimal structural efficiency. The DarkAero design uses mostly spread tow plain weave, locally reinforced with unidirectional (UD) fabrics in areas that have most or all of their load in one direction. Localized stiffness is provided with a mix of aramid honeycomb, foam or Lantor (Veenendaal, The Netherlands) Soric infusible core. For smaller and more complicated geometries like the carbon fiber spinner — the cone-like part in front of the propeller — DarkAero uses 2x2 twill for its superior drape and conformability. Parts are room-temperature cured on tools after infusion and later post-cured at the same time as the bonded subassemblies.

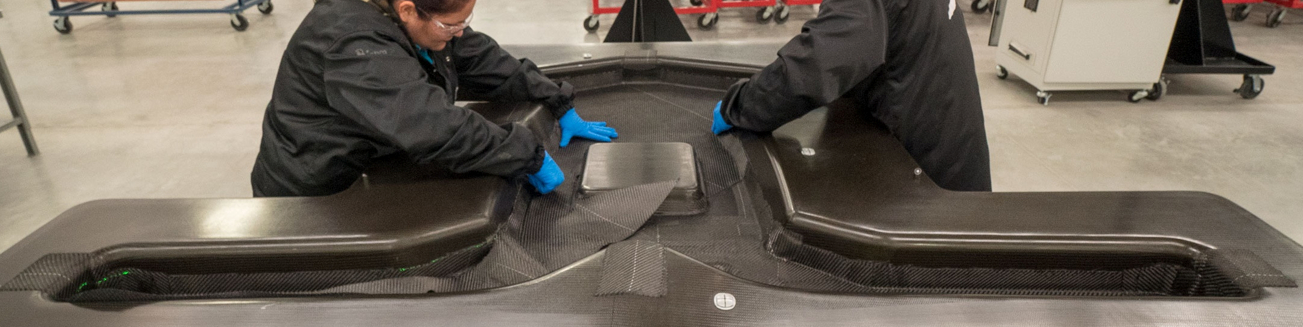

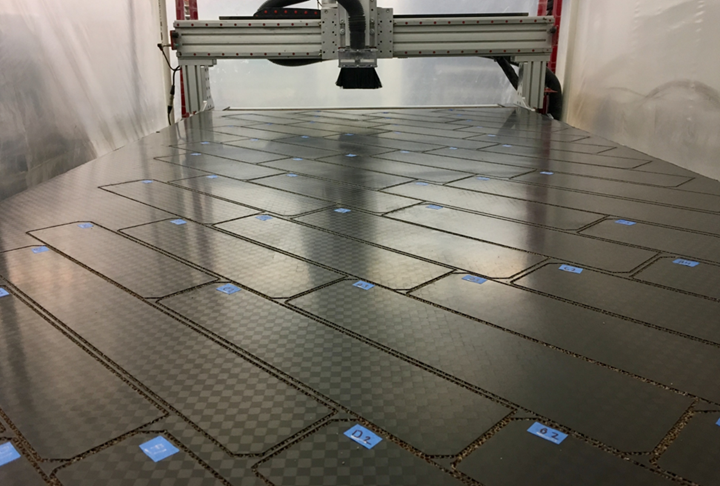

DarkAero’s substructure is kept simple and low cost with carbon fiber fabric faced sandwich panels made in large 4 × 8-foot sheets. The final substructure shapes are CNC machined and the subassembly is bonded together at elevated temperatures with paste adhesive. Curing is performed in ovens; autoclaves are too expensive, and out-of-autoclave materials are improving to the point where oven cures are sufficient.

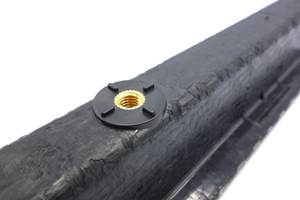

DarkAero goes beyond the normal skins and substructure for application of composites — even the aircraft’s brackets, hardpoints and bell cranks are made by machining solid billets of infused, multi-axial noncrimp carbon fiber fabrics, which enable the company to build up quasi-isotropic laminates quickly.

Carbon fiber/epoxy over aramid honeycomb panels are fabricated in 4 × 8-foot sheets and then CNC cut to shape to make very structurally efficient ribs, shear webs and bulkheads for the DarkAero 1. Photo Credit: DarkAero

DarkAero recognizes that there are a number of challenges in designing and building a high-performance single-engine aircraft, but as Keegan Karl, one of the three Karl brothers who founded DarkAero, put it, “Understanding the nuances of composite design and manufacturing is a key piece of the puzzle.”

Light Sport Aircraft M&P

Much like Experimental aircraft, wet layup or infusion have often been used for LSA composites, but prepregs have been increasingly employed to improve quality and performance. Flight Design GmbH (Hoerselberg-Hainich, Germany), one of the more popular builders of LSAs, has moved away from wet layup to Hexcel (Stamford, Conn., U.S.) M79 prepreg for its new F2-LSA (which the company is also working to certify as the F2-C23).

And it’s not just land and air where LSAs can be found — Icon Aircraft’s (Vacaville, Calif., U.S.) very sporty A5 is an amphibian, meaning it can land either on runways or bodies of water like lakes or ocean bays. Icon decided from initial design to use prepregs to derive maximum performance benefit for its unique land-sea application. Additionally, it sees manufacturing advantages in prepreg: less labor, quicker processing and more consistent results than wet layup.

Center spar layup of carbon fiber/epoxy prepreg for the Icon A5 LSA. Photo Credit: Icon Aircraft

Icon chose composites because they allow the company to fabricate very complicated shapes easily and are corrosion resistant, the latter being a very important consideration for a plane that might spend a considerable amount of its life on or around water. More than 95% of the Icon LSA structure is made using 2x2 carbon fiber twill/epoxy prepreg with some local areas of UD standard modulus carbon fiber prepreg to reinforce highly loaded (and highly directional loaded) zones.

To reduce production costs and improve repeatability, Icon CNC cuts all ply details and uses laser projectors and templates to locate the plies in the tools during hand layup. Instead of adding additional plies for structural stiffness in certain areas, closed-cell foam core is used as needed to increase the stiffness of the structure, for very little weight penalty and high cost savings. The foam core is CNC machined and a beveled ramp is added to ease ply transitions. It can then be heat-formed to shape. Composite parts are generally oven-cured, but for certain highly loaded structures such as the wing spar, an autoclave is used to reduce porosity and yield the very best quality and performance possible.

Carbon fiber-reinforced epoxy is being hand laid to the uniquely shaped main aft bulkhead for the Icon A5. Numerous Virtek (Waterloo, Ont., Canada) laser projectors speed location of ply details. Photo Credit: Icon Aircraft

Assembly is mostly paste bond (epoxy) using grit blasting and solvent wiping for surface preparation. Bond gaps are designed into the assembly and controlled using bonding fixtures. Mixing and application of paste adhesive is all done by hand. Initial cure is at room temperature followed by an elevated post-cure.

Bonded assembly of the fuselage, center wing box and sponsons (for stability on the water) of the Icon A5 amphibious airplane. Photo Credit: Icon Aircraft

Despite flying in potentially harsh conditions, the performance of the composites seems to justify the original design selection rationale. Icon’s director of engineering, Rodolfo Correa, says that after eight years of service history and several of the airframes with more than 1,000 flight hours, there have been no failures in bonded joints or laminated parts. So satisfied is the company with the results that Icon is moving to certify the A5 in addition to continuing to offer the LSA model of the A5.

Certified aircraft M&P

First-generation general aviation certified planes (with significant production runs) with a high composites content such as the Diamond Katana/DA-20 or the Cirrus SR20 were generally E-glass, because of its low cost and ease of inspection (being semi-translucent, a strong backlight can reveal most defects with a simple visual inspection).

However, second-generation planes such as the Diamond DA-42 or the Cirrus SR22 increasingly applied carbon fiber and/or S2 glass, while third-generation craft like the DA-62, SF50 Vision Jet and Epic’s E1000 are moving to mostly or all-carbon fiber construction for its structural efficiency.

Similarly, the trend in resin systems is to choose higher performing (tougher and higher glass transition temperature (Tg)) epoxies that enable darker paint as well as improve damage resistance. Processing is generally hand layup of prepregs with either oven or autoclave cures.

The Cirrus Aircraft (Duluth, Minn., U.S.) series of SR aircraft are said to be the best-selling single-engine piston general aviation planes in recent years and have been all-composite since their inception in the late 1990s. While the company’s latest composite advancements remain undisclosed, Cirrus has had a long-standing relationship with Toray Advanced Composites (TAC, Tacoma, Wash., U.S.) using its BT250 epoxy systems and TC275-1. The latter is a 275°F cure vacuum bag only (VBO) epoxy prepreg used on the SF50 Vision Jet. Processing is conventional hand layup with paste-bonded assembly.

Diamond Aircraft designed and built its own in-house, on-demand equipment for controlling resin application to dry fabrics to create “wet preg.” Photo Credit: Diamond Aircraft

One of Cirrus’ major competitors in the all-composite certified general aviation market is Diamond Aircraft (Wiener Neustadt, Austria). Leveraging its fiberglass powered-sailplane experience, Diamond still uses “wet preg” as a semi-automated way to help control wet layup resin application.

Much like Cirrus, over time Diamond has upped the share of carbon fiber in its designs from 10% (versus 90% fiberglass) in the early DA20 C1 models, to 50% in the DA42, and with the latest designs — DA50 RG and DA62 — the percentages have completely flipped to 90% carbon fiber and only about 10% fiberglass. Diamond has used high strength and standard modulus carbon fiber, which increases availability of the material (and associated data) and improves airframe performance, propelling its increased use.

Diamond’s “wet preg” process generates on-demand, in-house prepreg (or wet layups, depending on your perspective). Rolls of dry fiber are run through custom-designed equipment that meters a certain amount of low-viscosity epoxy resin to produce a wet prepreg that is immediately cut to shape and laid up in molds. The original resin used in the DA20, DA40 and DA42 was L160 or L285 epoxy from Momentive (Esslingen am Neckar, Germany). Newer designs (DA42-VI, DA50 RG and DA62) moved to RIM935 infusion epoxy by Westlake Epoxy (formerly Hexion, Columbus, Ohio, U.S.) for its high Tg. Early models of Diamond were limited to most or all-white paint schemes due to the low Tg of the L285; moving to the RIM935 has allowed the company to add new and dramatic color schemes which are generally preferred by customers.

Layup of carbon fiber/epoxy “wet preg” for the right-hand fuselage of a Diamond DA50 RG. Photo Credit: Diamond Aircraft

The handling of wet preg plies can be challenging and sometimes a bit messy; Diamond has considered introducing automated layup technology to help reduce cycle times and ease technician workload. Diamond has also added resin infusion to its processing repertoire — using it for parts which are more porosity-critical such as carbon fiber spars (for structural reasons) and fiberglass radomes (lower porosity for better electromagnetic transmission translating to better radar performance).

Diamond’s bonded assemblies use peel ply and sandpaper for surface preparation. The bondline resin is the same as the native wet preg but thickened to a paste with cotton flakes or microballoons. Mixing and application is all done by hand. The adhesive cures at room temperature followed by the entire structure (laminate and bondline) receiving an elevated temperature post-cure.

Diamond DA50 RG fuselage halves and frames are being prepped for final assembly bonding. Note that the vertical stabilizer is an integral part of the large fuselage assembly. Photo Credit: Diamond Aircraft

In Diamond’s 40 years of experience, the company says it has never had a plane retired due to composite issues. The airframes are inspected every 6,000 flight hours and generally have no findings or repair work needed. “Composites are in our DNA,” says Diamond Aircraft’s head of design organization, Robert Kremnitzer, reflecting back on the extensive service life for Diamond’s products. “We wouldn’t think any different. We wouldn’t design any different. We think it’s a great material.”

Editor’s note: CW toured Diamond Aircraft in 2017 and published a report, which can be found here.

Epic Aircraft (Bend, Ore., U.S.) turned a popular kit (Experimental) plane into one of the highest performing certified turboprops around. Powered by a single Pratt & Whitney Canada (Longueuil, QC, Canada) PT6A-67A turboprop (whose family of venerable PT6 engines has recently just topped 1 billion flight hours), the E1000, and now E1000 GX, can cruise at 380 miles per hour with 2,000 miles of range at up to 34,000 feet in pressurized comfort.

This Epic E1000 GX fuselage half is laid up with Toray 2510 carbon fiber/epoxy prepreg. Note the honeycomb core bays with violet-colored Henkel EA 9696 epoxy film adhesive. Photo Credit: Epic Aircraft

It was that performance and durability (e.g., fatigue resistance, especially critical for a pressurized fuselage) that first drew Epic to carbon fiber composites. Along the seven-year process to gain FAA type and production certification, it learned and refined the design through testing and retesting, finally achieving a very robust composite airframe tested to about twice the highest load expected during service.

In 2021, Epic certified the E1000 GX, which is now the company’s standard production plane. The GX upgrades the avionics and puts a five-bladed composite prop on the front of the PT6A-67A turboprop. The new composite prop improves takeoff performance and at the same time reduces noise and increases passenger comfort.

Brock Strunk, chief engineer for Epic, cut his composite certification teeth with Lancair and has extensive experience in industry-wide efforts to support shared composite material databases to help general aviation. Thse efforts include Advanced General Aviation Technology Experiments (AGATE), National Center for Advanced Materials Performance (NCAMP) and CMH-17. Strunk is a major proponent of public databases, which allow for smaller aircraft companies to more easily incorporate advanced composite materials into their designs.

Epic E1000 GX fuselage halves, bulkhead and firewall are prepped for bonding. In the foreground is a carbon fiber/epoxy one-piece (virtually from wingtip-to-wingtip) wing spar — one of two for flight load redundancy. Photo Credit: Epic Aircraft

Epic hand lays carbon and fiberglass 2510 epoxy prepreg from TAC to fabricate the approximate 550 composite parts in each shipset. Close technical relationships with its composite and adhesive material suppliers have been critical and Epic uses its technical expertise to help optimize fabrication processes. In addition, by choosing composite materials that were already qualified and had public databases, Epic was able to use the money saved to develop a deeper understanding of how process variability affects final properties to implement a robust composite production system.

The majority of Epic’s parts are made from fabric prepreg with highly loaded structure such as wing and horizontal spars using UD prepreg. Localized stiffness is typically provided with Hexcel aramid/phenolic honeycomb over-expanded (OX) core and Henkel (Madison Heights, Mich., U.S.) Loctite EA 9696 Aero epoxy film adhesive with some limited use of foam core mainly in complex geometries where it can be heat-shaped. Assembly is bonded paste adhesive joints; the epoxy paste adhesive, also from Henkel, has extra thickeners mixed in to help resist slump during the bonding of the fuselage halves and close-out of the wings.

The final structural assembly of the Epic E1000 GX. The forward fuselage carbon fiber structure is a pressure bulkhead that also forms part of the firewall. Blue areas are surfacing film containing copper lightning protection. Note the leading edges of the wing are left bare for later bonding of inflatable de-icing boot systems. Photo Credit: Epic Aircraft

Potential future advances

Technological growth for composites in general aviation will likely be driven by one single factor: cost. General aviation OEMs are willing to explore new, lightweight options and processing techniques to make airframes more fuel efficient (or even electrified or hydrogen powered), but moving from tried-and-true materials and processes can be cost-prohibitive. And not just from the price of raw materials, but also the time and cost to qualify and certify new composite structure.

Published databases like NCAMP and CMH-17 are a major help to small manufacturers in adopting new materials; material suppliers should consider including a basic set of allowables with any new structural composite material system they bring to market.

Driven by market projections of composites on general aviation aircraft as well as advanced air mobility (AAM), the composites industry is moving to develop higher performing composites that simultaneously reduce material, processing and in-service costs.

Advances in toughened epoxy resins achieve cure more rapidly at lower temperatures and pressures while still providing autoclave-like properties, enabling use of stiffer intermediate modulus carbon fibers in UD formats. UD fibers are roughly 25-50% more efficient than their woven cloth counterparts. Together, significant weight reductions are possible and less internal wing space is taken up, leaving more room for fuel.

High-performance semi-crystalline thermoplastic resins such as polyetheretherketone (PEEK) and polyetherketoneketone (PEKK) will continue to come down in price and offer much better out-of-plane and damage tolerance properties when compared to epoxy — even toughened epoxies. High-temperature processing requirements bring their own set of challenges, but new processing and modeling can help address those.

Carbon fiber, especially intermediate modulus, will find general aviation primary structure applications for its unbeatable structural performance, particularly in stiffness. New advances in large-tow carbon fibers and new production plants with additional carbon fiber capacity add up to a reduction in cost of the carbon fiber, further driving its utilization across general aviation.

Research and development (R&D) of new composite processes, including advanced fiber placement (AFP) and automated tape laying (ATL), not only yield very high quality and consistent composite structures, they take advantage of UD carbon fiber for the ultimate structural efficiency and can also fabricate large, integrated, complex structures, reducing assembly costs. Another processing technique, press forming, which uses heated tools and mechanical force to cure, offers the possibility of reducing part processing cycle time from hours or days to minutes.

A modest proposal to accelerate implementation of innovation

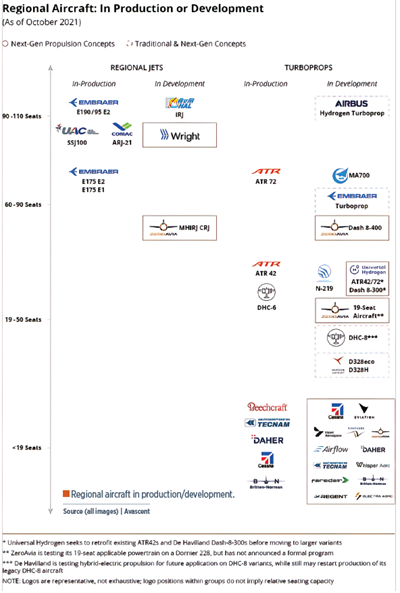

The current revolution in local and regional air transportation (as captured by the term AAM) that includes vertical takeoff and landing (VTOL), short takeoff and vertical landing (STOVL) and short takeoff and landing (STOL), as well as conventional fixed-wing transports, offers a unique opportunity for general aviation companies to leverage materials and technologies to drive their industry forward.

Imagine a partnership where an established general aviation company teams with an up-and-coming AAM group (or the teaming could involve multiple partners from both general aviation and AAM). Jointly working with material suppliers, they cooperatively define cost, processing and performance goals for a suite of materials (prepregs, adhesives, etc.). The materials are qualified through an FAA-approved data system such as NCAMP or CMH-17 while the high-rate, low-cost processing is developed and validated through a government/academia composite fabrication R&D facility such as the National Institute for Aviation Research’s (NIAR) Advanced Technologies Lab for Aerospace Systems (ATLAS) center in Wichita, Kan., U.S. The partnership could jointly invest in a single, multi-purpose production facility or each leverage the knowledge and data to create their own factory.

By working together, AAM organizations gain invaluable knowledge from the years of composites design, analysis and fabrication expertise the general aviation companies have developed over the years. At the same time, general aviation companies secure new resources to help reduce non-recurring costs to implement new structurally efficient materials and cost-reducing processes.

Overall, the future looks bright for composites across all sectors of general aviation. Leveraging materials and processes being developed for other markets will enable significant performance gains (taking more farther and faster for less fuel burned) while simultaneously improving durability and reducing acquisition costs.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreRead Next

Regional air mobility: A meaningful first step in the electric aviation revolution

Electrification of fixed-wing, <50-seat regional aircraft might stimulate a new era of growth that could help pave the way for advanced air mobility (AAM) aircraft.

Read MoreGeneral aviation: Reconceiving the personal plane

Enabled by FAA rule changes, small plane manufacturers today are moving beyond the private “pleasure” craft to cutting-edge technologies engineered to offer an affordable means to avoid urban gridlock.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More