Barrday

Barrday Corporation

86 Providence Street

Millbury, MA 01527 US

508-581-2100

composites@barrday.com

barrday.com

About Barrday

Barrday is a leading advanced material provider for the composite and protective markets. For over 60 years, we have developed technologically advanced fiber reinforcements and prepregs for customers in the aerospace, defence, energy, industrial, and protective markets.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Barrday Supplies the Following Products

- Aramid, 4-harness (crowsfoot)

- Aramid, 5-harness

- Aramid, 8-harness

- Aramid, Basket-weave

- Aramid, Other

- Aramid, Twill

- Aramid, Woven roving

- Aramid, Yarns

- Bismaleimide, Fabric

- Bismaleimide, Solvent-based

- Carbon fiber composite

- Carbon, 4-harness (crowsfoot)

- Carbon, 5-harness

- Carbon, 8-harness

- Carbon, Basket-weave

- Carbon, Other

- Carbon, Plain-weave

- Carbon, Twill

- Carbon, Woven roving

- Carbon, Yarns

- Coating and painting

- Continuous laminating

- Cyanate ester, Fabric

- Cyanate ester, Mat

- Cyanate ester, Other broadgoods

- Epoxy, >12K tow

- Epoxy, 12-inch tape

- Epoxy, 250 F cure, <12K tow

- Epoxy, 250 F cure, >12K tow

- Epoxy, 250 F cure, 12-inch tape

- Epoxy, 250 F cure, 3-inch tape

- Epoxy, 250 F cure, 6-inch tape

- Epoxy, 250 F cure, 60-inch tape

- Epoxy, 250 F cure, Fabric

- Epoxy, 250 F cure, Mat

- Epoxy, 250 F cure, Other broadgoods

- Epoxy, 250 F cure, Other tape

- Epoxy, 250 F cure, Roving

- Epoxy, 3-inch tape

- Epoxy, 350 F cure, <12K tow

- Epoxy, 350 F cure, 12-inch tape

- Epoxy, 350 F cure, 3-inch tape

- Epoxy, 350 F cure, 6-inch tape

- Epoxy, 350 F cure, 60-inch tape

- Epoxy, 350 F cure, Fabric

- Epoxy, 350 F cure, Mat

- Epoxy, 350 F cure, Other broadgoods

- Epoxy, 350 F cure, Other tape

- Epoxy, 350 F cure, Roving

- Epoxy, 6-inch tape

- Epoxy, 60-inch tape

- Epoxy, Fabric

- Epoxy, Film

- Epoxy, Mat

- Epoxy, Other

- Epoxy, Other broadgoods

- Epoxy, Other tape

- Epoxy, Paste

- Epoxy, Roving

- Epoxy, Solvent-based

- Epoxy, toughened, 12-inch tape

- Epoxy, toughened, 3-inch tape

- Epoxy, toughened, 6-inch tape

- Epoxy, toughened, 60-inch tape

- Epoxy, toughened, Fabric

- Epoxy, toughened, Mat

- Epoxy, toughened, Other broadgoods

- Epoxy, toughened, Other tape

- Epoxy, toughened, Roving

- Epoxy, Water-based

- Fabric

- Other thermoplastic prepregs

- Other, >12K tow

- Other, 3-inch tape

- Other, 4-harness (crowsfoot)

- Other, 5-harness

- Other, 6-inch tape

- Other, 60-inch tape

- Other, 8-harness

- Other, Basket-weave

- Other, Fabric

- Other, Mat

- Other, Other

- Other, Other broadgoods

- Other, Other tape

- Other, Plain-weave

- Other, Solvent-based

- Other, Twill

- Phenolic

- Phenolic, >12K tow

- Phenolic, 12-inch tape

- Phenolic, 3-inch tape

- Phenolic, 6-inch tape

- Phenolic, 60-inch tape

- Phenolic, Fabric

- Phenolic, Mat

- Phenolic, Other broadgoods

- Phenolic, Other tape

- Phenolic, Roving

- Phenolic, Solvent-based

- Phenolic, Water-based

- Polyester, unsaturated, Fabric

- Polyester, unsaturated, Mat

- Polyester, unsaturated, Other broadgoods

- Polyimide, Fabric

- Polyimide, Mat

- Polyimide, Other broadgoods

- Polyimide, Solvent-based

- Prepreg

- Silicone, Solvent-based

- Tape, unidirectional

- Testing, materials

- Tooling prepreg

- Vinyl ester, Fabric

Trade Names Offered by Barrday

Editorial, News, and Products

-

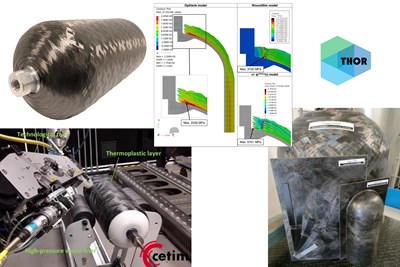

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

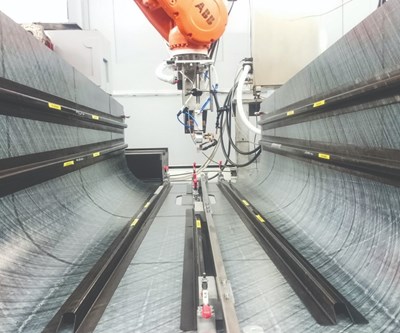

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

-

I want to say two words to you: “Thermoplastic tapes”

Thermoplastic tapes are not new to composites, but they soon will join the primary aerostructures material palette and could be their future.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Composites in Class A body panels: Evolution continues

Low-density SMCs lead the way as fiber-reinforced polymers make headway in auto components that must please the eye.

-

Carbon/epoxy Cadillac hood

Automated process for prepreg hood inner/outer cuts weight by 20% and yields Class A exterior out of the autoclave.

-

Carbon/epoxy Cadillac hood in production

While they typically keep their research efforts close to the vest, automakers and automotive Tier suppliers nevertheless are always in the process of evaluating the multitude of materials available for lightweighting.

-

Cruise-capable rotorcraft exploits the performance of composites

The Carter Aviation Personal Air Vehicle combines the best of fixed-wing aircraft and helicopters, in an all-carbon composite design.

-

Why South Carolina? Why now?

CW guest columnist Tom Lemire (T.F. Lemire Consulting Inc., Irvine, CA, US), comments on the aerospace industry's current attraction to this particular spot on the US map and wonders if it's the beginning of a trend.

-

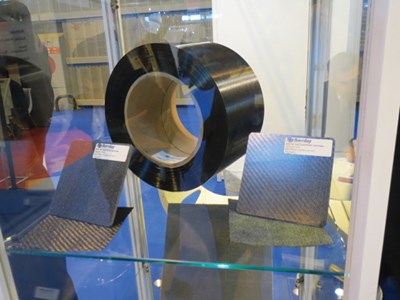

2013 JEC Europe new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

SAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Antiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

-

SAMPE 2010 Seattle Showcase

SAMPE’s first-ever foray into Boeing Country wrapped up with the M&P organization’s biggest draw this decade.

-

Composites on the frontlines

Armored vehicle applications on the ground and in the air fuel a growing, evolving market forhigh-performance materials.

-

Are high-temp thermosets ready to go commercial?

Developed for the U.S. military, these high-performance matrices are branching out into wider use.

-

Advances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.