2016 Farnborough International Airshow Report

Composites are not the novelty in aerospace that they once were, but there was still much to see at Farnborough this year.

Share

Read Next

Held every other year (alternating with the Paris Air Show, in Le Bourget, France), the Farnborough International Airshow is a premier European aerospace showcase. Its 2016 edition took place July 11-15 at Farnborough Airport (Farnborough, Hampshire, UK). We noted in our report on the 2014 event that at the Farnborough Airshow and others like it, the display of composite aerostructures had become a common sight as they earned a place in many new aircraft programs, but it was acknowledged even at that time that composites were a bit less conspicuous than they had been at previous Farnborough shows.

First impressions

So it was with a bit of initial disappointment that, to this observer, there appeared to be even fewer composite parts about than in 2014, and The Boeing Co.’s (Chicago, IL, US) much anticipated press conference, based in part on its annually published Current Market Outlook, did not even mention composites!

Indeed, the single-aisle aircraft segment of the commercial aircraft market still poses a serious challenge to the composites industry; we have succeeded in getting 50% of the market for structures on the long-range aircraft, but on single-aisle planes, the two market leaders still have metallic wings and fuselages. Boeing reports that this sector represents 47% of the current backlog, and to this observer, the composites industry does not seem concerned at these missed opportunities. Thanks does go out to Bombardier (Montreal, QC, Canada) and the Irkut Corp. (Irkutsk, Russia) for these companies’ faith in new materials. Irkut’s MS-21 narrowbody single-aisle (130-210 passenger) commercial jet, for example, is 30% composites, featuring, notably, an out of autoclave (resin-infused, oven- cured) wing and wingbox — a first for large, primary aerostructures.

Second Impressions

On reflection, the absence of overt reference to composites at Boeing’s press event is, possibly, a good thing: It indicates that composite materials have become an accepted industry norm and that any entirely new aircraft will likely have composite wings and, probably, a composite fuselage to match. Certainly, as the show progressed, there were encouraging signs. In the flying display, there was a lot of carbon fiber flying around: the first Royal Air Force F-35 refueling from an A400M; the first Swiss Air Bombardier CSeries; and also the first European display of the exception to one’s composite expectations, Boeing’s 737MAX.

And if the OEMs were a bit reticent on the subject of composites, the supply chain proved less so. The following is a selection of the more innovative composites applications on display in the exhibition halls.

GKN Aerospace (Redditch, Worcestershire, UK) had an interesting display of structures in its pavilion. Thermoplastic composite structure had a conspicuous presence, reflecting GKN’s recent acquisition of Fokker Aerostructures (Hoogeveen, The Netherlands). A number of GKN team members were from The Netherlands, including Fokker’s R&D director Arnt Offringa, who explained to visitors the options for applying stiffeners to panels using various joining techniques. GKN technical sales engineer Ali Ahmed described a new-generation de-icing technology that uses much thinner heating layers than those on existing systems, yielding benefits in reduced weight and less energy consumption.

The exhibition was full of UAVs built with varying amounts of carbon fiber. However, the biggest (Fig. 1, p. 34) was the result of an Anglo-American joint program. It is a leading contender for the US Army’s Joint Tactical Aerial Resupply Vehicle. The companies involved are, from the US, Belcamp, MD-based SURVICE Engineering, and Malloy Aeronautics from Berkshire, UK.

In The Netherlands, Airborne Development BV (The Hague) is participating with Fokker and the Amsterdam-based NLR (Nationaal Lucht- en Ruimtevaartlaboratorium or National Aerospace Center) in a CleanSky program to make an innovative flap for business jets. The flap’s structural integrity depends on the load introduction rib on display at Airborne’s stand, a very complex part made by RTM (Fig 2). Also on display was an automated tape laying head developed for use with 150-mm prepreg tape (Fig. 3).

DTC (Dutch Thermoplastic Components BV, Almere, The Netherlands) is well known for its expertise in press-forming thermoplastic composites for aerospace applications. It had three recent innovations to report: The development of its own thermoplastic UD tape; a pick-and-place layup machine; and, on the marketing side, a start at supplying structures to the auto- motive market, with a contract to make 400 seatbacks for an unnamed customer.

CTRM (Melaka, Malaysia) demonstrated its expanding capability with the announced delivery of its first helicopter structure to Airbus (Toulouse, France), the fenestron (the duct that surrounds the tail rotor) of the new H130 rotorcraft, as well as an Airbus A350 XWB fan cowl, which is supplied to UTC (Chula Vista, CA, US).

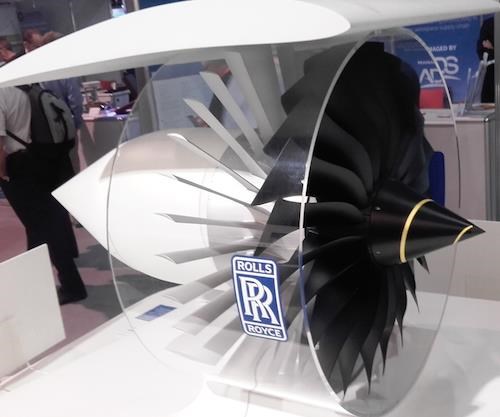

Back at the end of the past century, unducted ban blades were forecast to power the next generation of aircraft. Low-cost oil and problems with noise put an end to this program. Now the concept has been renamed an open Rotor and is very much a live project, again, under the CleanSky program. The effort, led by Safran (Paris, France), has reportedly reached the stage where ground testing is imminent. Models of the system were on display (Fig. 4), together with an even more futuristic system, the Rolls- Royce (Derby, UK)/Airbus E-Thrust System. The latter comprises an embedded gas-turbine that drives a superconducting generator used to power distributed electrically driven fans (Fig. 5, p. 36) that will reduce fuel consumption, and reduce emissions and noise on future aircraft.

TWI (Cambridge, UK) showed a demonstrator of a new, patented application of a very old phenomenon, which it has named Surflow. Surflow employs a property of electromagnetic waves that enables them to be transmitted through linear materials, such as a CFRP panel, that incorporate both dielectric and conductive materials. On the TWI stand, a composite panel was set up and used to transfer data (in this case, pictures from a video camera) through the panel’s length to a small monitor, which displayed the pictures taken by the camera (Fig. 6). This technology works even if the panel suffers ballistic damage, making it a more damage-tolerant data transfer system than those that require embedded copper wires or fiber- optics. One of the first applications being studied is in UAVs. The Surflow process also has potential application in nondestructive testing, in the form of real-time composite monitoring. Subtle changes in the transmitted electromagnetic waveform could, for example, enable damage to an aircraft component to be identified immediately, as a potential alternative to costly scheduled groundings for lengthy manual inspections.

Williams Advanced Engineering (Oxfordshire, UK), primarily known as a Formula One racing team, is diversifying its engi- neering services company by expanding into aerospace. Thus its presence at the airshow. The company designs and builds Formula E electric racing cars. In this formula, all the cars have the same structure and suspension but may have different electric drive systems. The difficult bit is to design the car’s composite main structure so that it will contain the heavy batteries in the event of a crash (Fig 7, at left, p. 36).

IHI (Tokyo, Japan) had two composite engine parts on display (Fig 8, top right). These were the fan case and the structural guide vanes for Pratt & Whitney’s (East Hartford, CT, US) PW 1100G-JM, the new geared turbofan being fitted to the Airbus A320neo.

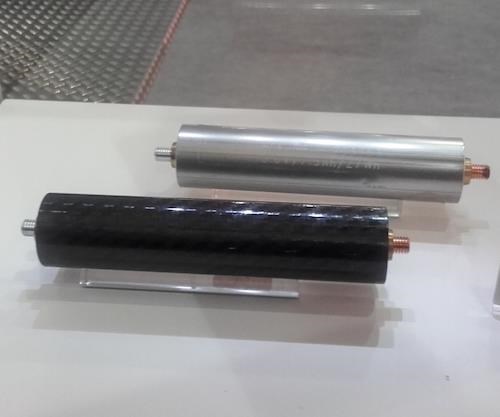

EAS (Nordhausen, Germany) demonstrated a new application for CFRP — cases for lithium-ion cells. Compared with the metallic cases currently in use, they save 50g each in weight, which seems like very little. However, the significance is obvious when one realizes that on a Proton rocket, there are 200 of these cells. This gives a total weight savings of 10 kg, a very important edge when launching satellites into orbit (Fig. 9).

The URT Group (Bognor Regis, UK) is building, for the Bloodhound hybrid car/rocket, the main structure from CFRP, including the driver’s cockpit. The Bloodhound project will attempt to push the World Land Speed Record past 1,000 mph (1,600 kph) in 2017. The Bloodhound struc- ture was on display on the URT stand where it attracted a lot of interest from aerospace engineers (Fig 10).

Aviation Week and SpeedNews presented a briefing on Commer- cial Aerospace Manufacturing in two sessions. The first, related to “Automation in Aerospace Manufacturing,” was of great interest to composites professionals: Craig Turnbull, from Electroimpact UK (Hawarden, UK), shared an interesting vision of future develop- ments in automation, including Quadbots — robots that can work alongside humans — and the need for more in-process inspection to eliminate time-consuming post-production NDT processes now used with composites.

It is encouraging, in an era when many civil aircraft look very similar, that 1 mm below the skins, they can be made from very different materials and these, in turn, can be processed in totally different ways. Fuselages can be made from conventional aluminum alloys, aluminum/lithium with or without the local use of Glare, or follow Boeing or Airbus twin-aisle practice and go for carbon/epoxy prepreg. Wings offer choices, but the industry seems to be focused on carbon/epoxy with some disagreement about the processes to be used. These can be conventional AFP plus auto- clave cure or infusion, where the choice is oven or autoclave cure. When it comes to flight-control surfaces, the selection is broader: thermoplastics are earning a share, as are OOA prepregs, RTM and SQRTM on the thermoset side.

All this makes composites engineering a really interesting career at present. Long may it continue.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More