Everyone is talking about “one-minute” cycle times as a means to increase composites’ acceptance in the automotive industry. But that drive for shorter production cycles through development of more time-efficient materials and processes is no less important in the aerospace world. As aircraft build rates continue to ramp up, the need to control the cost of aerocomposites is critical as well. Toward that end, changes are underway in design, materials and processes.

A new aircraft structure production concept, called Torreswing, aims to bypass incremental development and, instead, target disruptive change in fuselage and wing fabrication technology by eliminating conventional tooling and the use of fasteners during automated fabrication of large, one-piece monocoque structures. Developed by machinery manufacturer MTorres (Torres de Elorz, Navarra, Spain), this radical departure from the manufacturing norm made its debut in 2017. It was recognized with a JEC Innovation Award in the category Aerospace Process at the 2018 JEC World exhibition in Paris, and was exemplified by a demonstration fuselage on display at the MTorres stand.

CW had the opportunity to interview MTorres’ Integrated Assembly group’s key account manager for the technology, Luis Enrique de la Iglesia y Gotarredona, and R&D business development manager Iñigo Idareta, and thus got this exclusive look at how the process works.

Factory of the future

Composites’ use on commercial and general aviation (GA) aircraft has increased significantly over the past decades, and so has the use of automation in aerospace fabrication. Obvious examples are the use of automated fiber placement (AFP) to make the fuselage barrels of the Boeing 787, the wings of Airbus’ A350, the wing spars and wings of Boeing’s 777X, and, more recently, the FLEXMONT project’s process for robotic assembly of Airbus vertical tail planes (see “The future of CFRP aerostructures assembly”). That said, a great deal of touch labor is still required to assemble a finished plane.

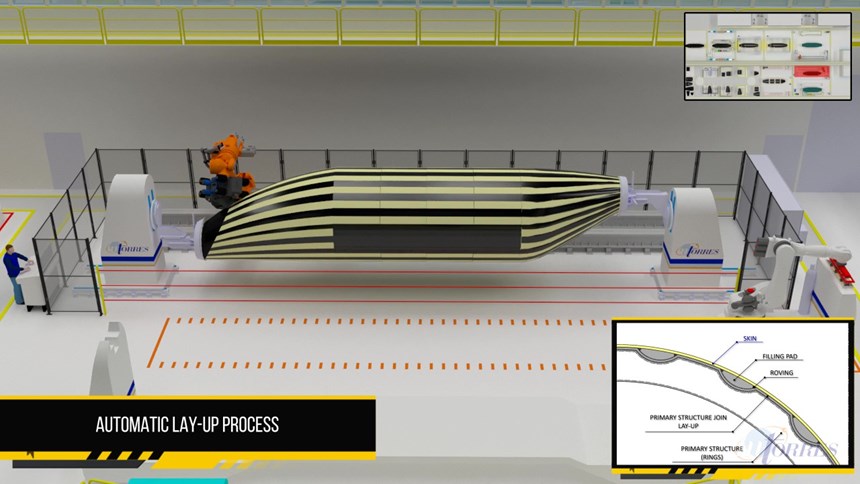

“The basis of the Torreswing process is a simple and easy-to-automate concept,” said De la Iglesia y Gotarredona, while illustrating the Torreswing process using two animated videos on display at the JEC World event, showing manufacturing steps that eliminate nearly all hand labor.

“A series of ‘elemental parts’ [Fig. 1] are made first.” He explained. “Those elemental parts then become the molds on which a monocoque fuselage is created.” In the case of an aircraft fuselage, those elemental parts include multiple carbon fiber composite frames, or rings, sized to the aircraft, and flat floor panels. Finished frames are butted together, adhesively bonded, and the floors placed inside the rings, to form the fuselage “skeleton” that is overwound via fiber placement to form the outer skin. The concept simplifies manufacturing and eliminates the metal fasteners that would otherwise join fuselage sections, or attach skin to stringers/frames. Wings and tail also would be made in a similar automated process, but no information is yet available for the wing process, which is still under development. “The current concept uses dry fiber and resin infusion, born from our experience in wind blades,” says Idareta, but he points out that “it can accommodate prepreg, or thermoplastic materials, as the customer wants.”

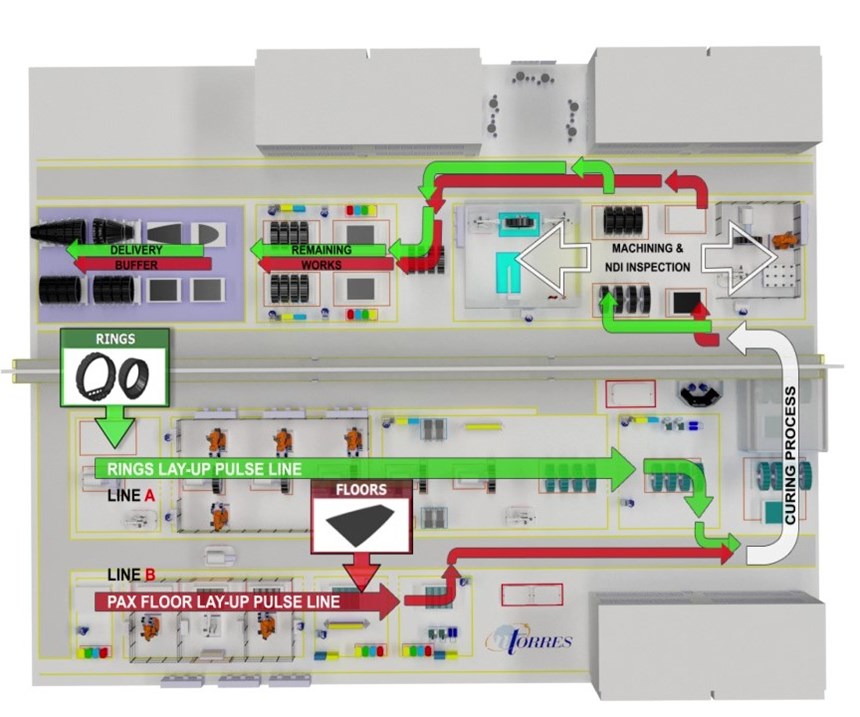

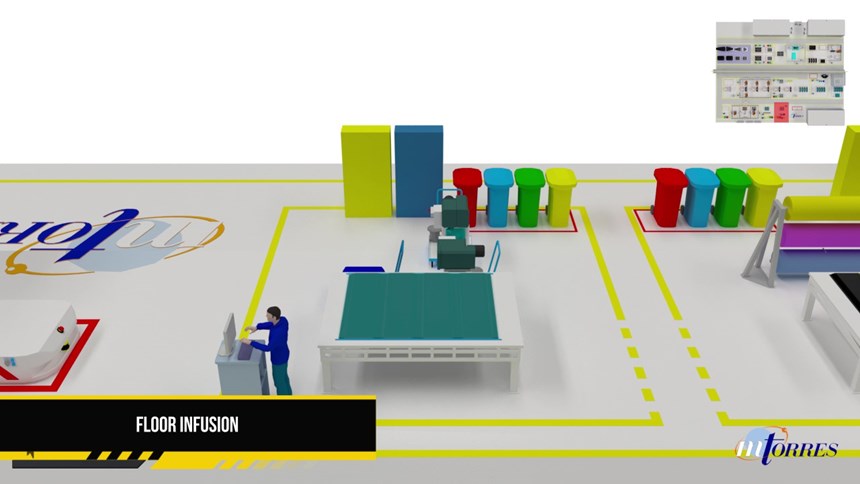

In the automated factory scenario, a small army of industrial robots and positioners shuttle parts from one station to the next, in a U-shaped workflow. “The factory and manufacturing concepts have increased the level of automation and reduced the number of required tasks, and it’s certainly doable today with the MTorres integration machines,” claims De la Iglesia y Gotarredona.

Assembling some essentials

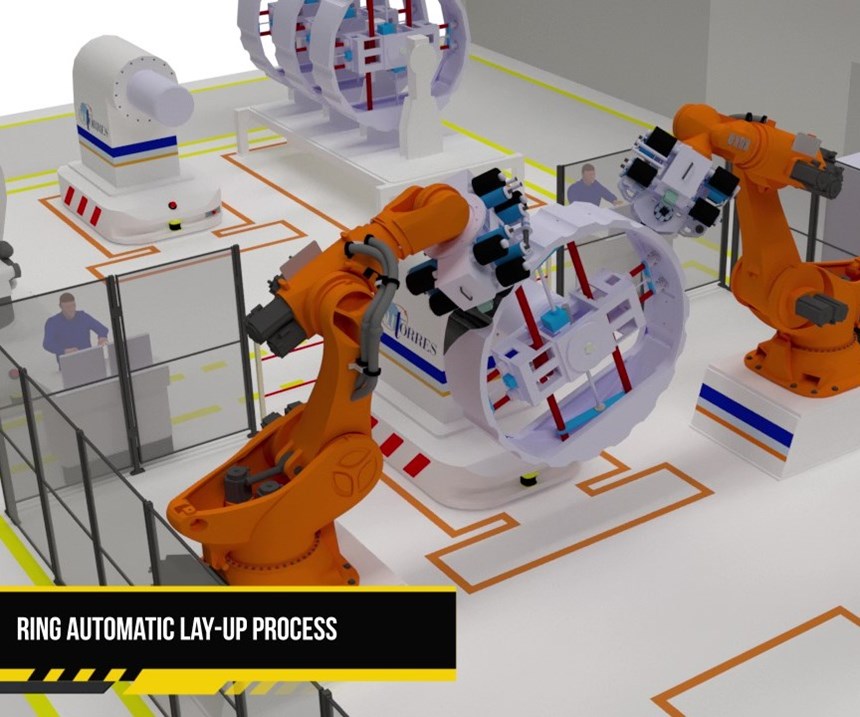

Phase I begins with the elementals. In the ring layup line, which runs parallel to the floor layup line (See Step 1), a robot transfers a metallic, collapsible ring mandrel, customized to the customer’s aircraft fuselage shape and size, onto a rolling positioner robot, equipped with a rotating headstock. The positioner moves into the next station, between two stationary MTorres AFP heads mounted on robotic arms, that quickly lay dry carbon fiber tape onto the mandrel surface, which is grooved on the outside (Step 2). More on the purpose for the grooves, below. The layup, as proposed in the concept, has 0°, 90° and ±45° plies, but can be optimized for each application. MTorres has developed its own dry carbon fiber tape for the process, using carbon fiber from a proprietary source, to which it adds a heat-activated thermoplastic binder, which functions both to give the tape some tack during layup and to enable infusion performance.

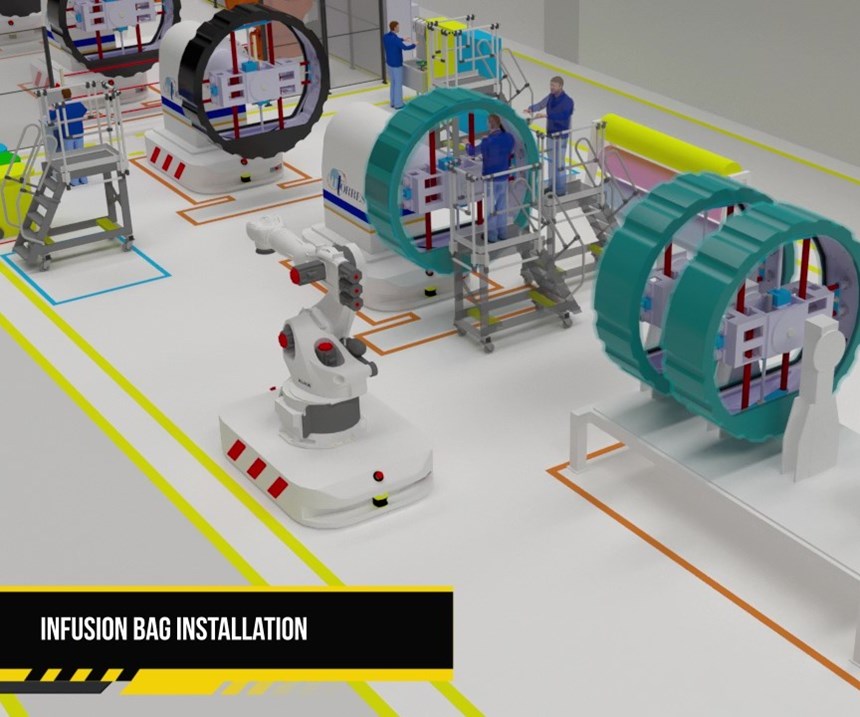

Note that, on the front and back side of each ring, a flat plate is fiber placed (Step 3), to create support for the floor panels. Next, the rings are prepared for resin infusion, with technicians bagging the layups and adding resin feeder lines. After bagging, a robot places the bagged rings on an automated transfer jig, which moves the rings to the infusion station, manned with technicians who oversee the resin infusion and vacuum.

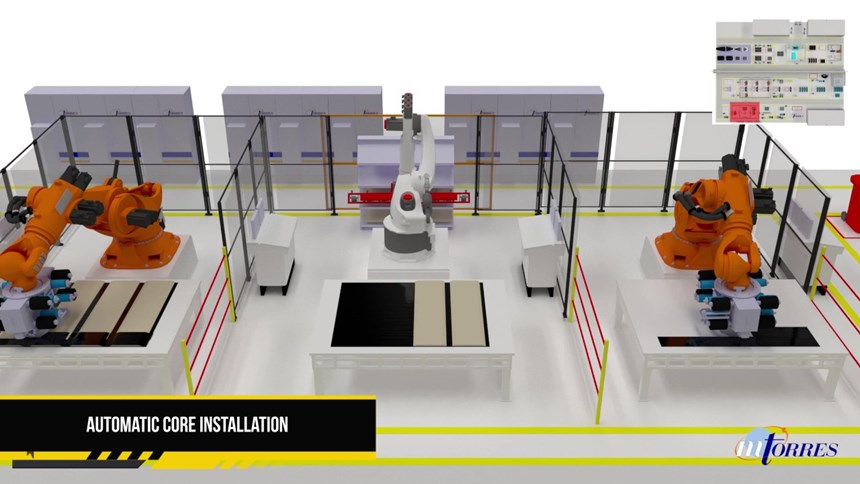

Meanwhile, at the floor layup line, three robotic arms work in concert to produce the flat floor panels. The first robot lays a 0°/90° laminate on a flat table mold, which is attached to a moving floor or jig feed line. The moving line takes that layup to a second station, where a robotic arm equipped with a pick-and-place end-effector places foam core over the laminate. At the next station, a third robot places a 0°/90° laminate skin over the core. The thickness and ply architecture of the panels are customized to the requirements of the application, says the company. Panels are largest, and square in shape for the middle part of the fuselage, but are produced in smaller, tapered shapes for the narrower tail and nose areas.

The completed, flat, cored panels are vacuum bagged and resin infused. At this point, small positioning robots automatically transfer the bagged and infused rings and floor panels to an oven for curing.

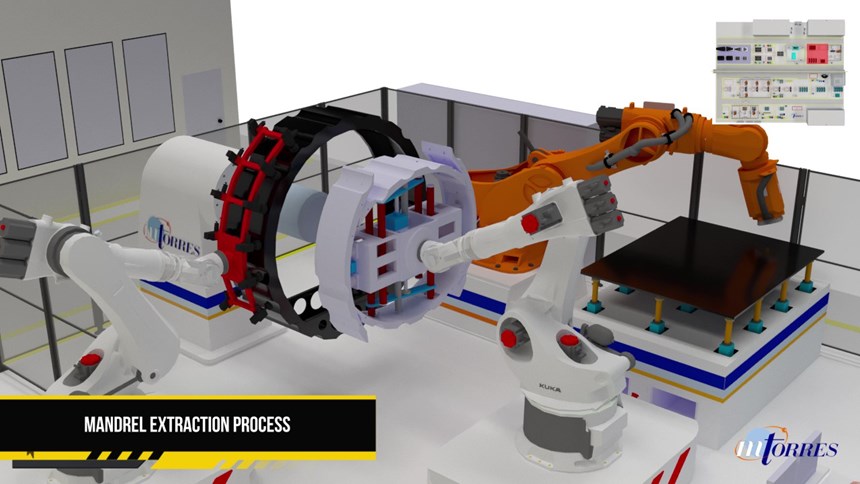

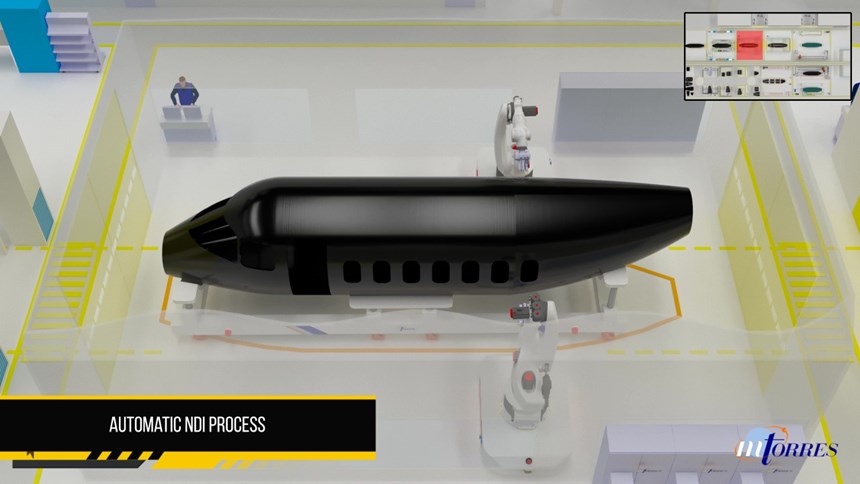

After cure, positioning robots ferry the cured parts to the next station, where the parts are unbagged and then placed in a workcell where a robotic arm with a cutting head performs machining steps. These include cutting holes in the flat plates on each ring (which will support the floor), to reduce weight and allow for wiring. The edges of the floor panels also are trimmed. As machining concludes, a robot extracts the mandrels from inside the cured rings and carries them back to the start of the ring layup line. Each part undergoes robotic nondestructive inspection (NDI) and then is carried to a final station where human inspectors look over each part and perform any remaining tasks prior to the next phase.

Flexible “flying mandrel”

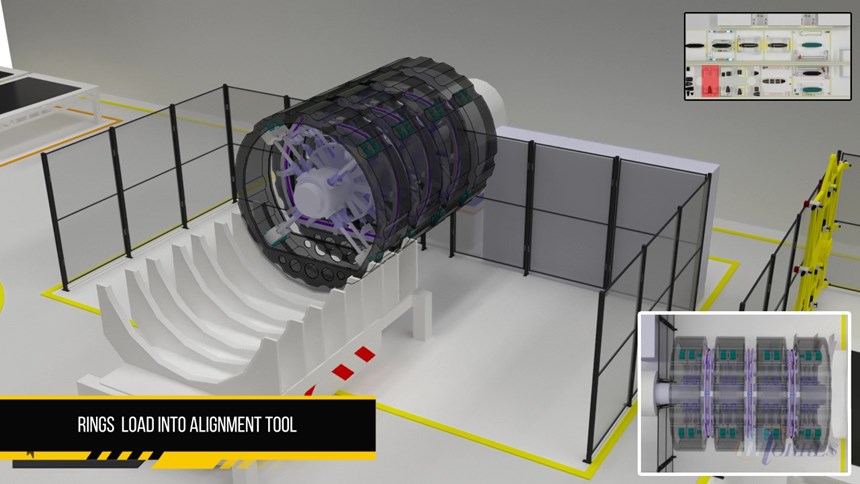

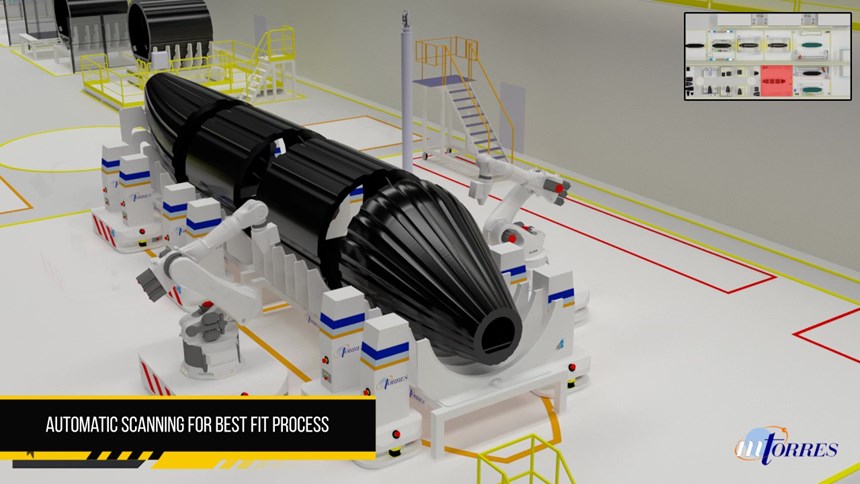

Completed elementals are assembled in a “final body join” process, within a second manufacturing hall. At the barrel assembly station, the completed rings are robotically loaded onto an alignment tool, from a transfer jig. Two robots take up positions on each side of the alignment tool and scan the rings to document their exact sizes, so that the best fit between them can be determined. Then, having determined the locations of gaps, the robots apply adhesive in greater or lesser amounts depending on the degree of misfit, and the alignment tool pulls the rings together to form a barrel, and ensure complete contact with the adhesive (Step 7).

At the next station, the bonded barrel is placed on another jig by a positioning robot, where the two scanning robots scan the floor panel and the floor support plates within the barrel for best fit. While one robot uses an end-effector to pick up the floor panel, the second applies more adhesive to bond the floor panel to the support plates. As each fuselage segment is bonded and finished, human workers install wiring, ducting and other systems beneath the floor panels or inside the fuselage space.

This process is repeated for each fuselage segment, from nose to tail, to form a structural assembly of rings and floors — in essence, a full-sized mandrel for the next step of the process (Steps 8-9). “No large metallic tooling is necessary. The carbon fiber elements, in any size or shape, act as mandrels or tools, and the remainder of the part is fiber-placed over those elements,” explains De la Iglesia y Gotarredona. And the use of adhesively bonded segments easily enables the use of larger, smaller and/or a greater or lesser number of segments necessary to create a fuselage of the length needed for a particular aircraft.

Rings replace stringers

At the next station, automated positioners place the structure in a station with rotating headstock and tailstock fixtures, and an MTorres fiber placement head begins placing dry fiber over the assembled rings to form the fuselage skin. The first ply is placed down into the grooves created by the rings, noted above (Step 10). Then, a robot places pieces of “filler” material into the grooves. Filler material could be foam, which could remain in place as insulating material, or another type of material that would be removed after cure of the skin, perhaps a dissolvable material, explains Idareta.

Says De la Iglesia y Gotarredona, “The grooves essentially act as stringers on the outside of the fuselage, when overwound with a skin to form a hat structure. This is a huge departure from today’s aircraft construction, which has longitudinal stringers and circular frames, typically made separately and installed by hand on the inside of the skin. The overwound grooved rings replace all of that.” He adds that in existing composite aircraft, MTorres calculates that stringers account for 30% of the material but 70% of the cost.

When the overwinding is complete — a five-layer laminate (Step 11), for a total thickness of less than 4 mm in the skin/ring structure, was used in the demonstrator (again, customizable for a specific aircraft) — cauls are placed, the entire fuselage is bagged, the skin is infused with resin and oven-cured. After cure, the fuselage is transferred to a machining cell, where a robotic head cuts window and door openings. Then it is taken to the final station before shipment (Step 12), where workers manually install required electronics and avionics, and add seating.

Is this the future?

The Torreswing process is designed to eliminate virtually all metallic fasteners and rivets, a significant weight savings over today’s aircraft, says the company. The adhesive used to bond the elemental rings, says Idareta, would be equivalent in weight to the shimming material used on conventionally built aircraft. And, with the high degree of robotic automation, cycle time and touch labor would be significantly reduced, resulting in process simplification and much lower manufacturing costs. For example, he adds, the number and size of part-specific tooling and the time needed for part production on that tooling would reduce manufacturing costs significantly. Other advantages include elimination of the autoclave in favor of oven cure, and use of dry fiber, reducing material cost.

Although it’s a TRL 6 project, only one demonstrator has been built so far — the fuselage shown at JEC, using equipment similar to that depicted in the step photos. But there are plenty of opportunities for a first customer trial. “There are a lot of proposals for new aircraft today, and we see a big market, which we believe would justify this factory concept.” Idareta acknowledges, of course, that certification of a bonded structure could be a challenge, given a regulatory environment that currently requires redundant fasteners for certification. “Our point of view,” he says, “is how to enable the plane of the future using the factory of the future. We’ve designed for automation, not just for manufacturing.” He also notes that a number of composites manufacturers in other industries are showing interest in the automated factory concept behind the innovative aircraft design, taking care to point out, “We’re not aircraft designers, we’re factory automation specialists.”

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreIndustrial composite autoclaves feature advanced control, turnkey options

CAMX 2024: Designed and built with safety and durability in mind, Akarmark delivers complete curing autoclave systems for a variety of applications.

Read MoreBusch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)