M. Torres Diseños Industriales, S.A.U.

M. Torres Diseños Industriales, S.A.U.

Ctra. Huesca, Km 9

Torres de Elorz, Navarra, Navarra 31119 ES

34 948 31 78 11

juan.solano@mtorres.com

mtorres.com

About M. Torres Diseños Industriales, S.A.U.

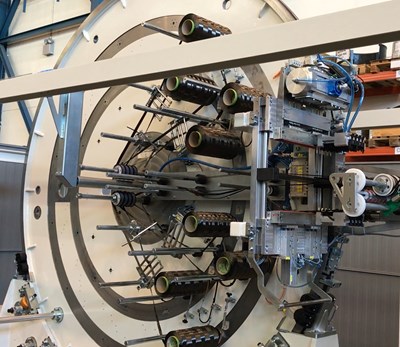

Designs/manufactures machine tools/assembly jigs for aerospace. Product range includes automatic tape layers, automatic fiber placement machines, 5-axis gantry routing machines/flexible tooling, ultrasonic inspection systems, ultrasonic cutting systems, 5-axis gantry laser scribing machines/flexible tooling, assembly jigs.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

M. Torres Diseños Industriales, S.A.U. Supplies the Following Products

- Automated fiber placement

- Automated fiber placement systems

- Automated tape laying systems

- CAD/CAM/CAE design

- Carbon fiber composite

- CNC machining equipment (multiaxis)

- Consulting, business development/acquisition

- Graphite, monolithic

- Inspection services

- Mandrels, aluminum

- Mandrels, steel

- Metal, aluminum

- Metal, other

- Metal, steel

- NDI equipment, ultrasonic

- Routers

- Tape laying

- Trimming equipment

Editorial, News, and Products

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

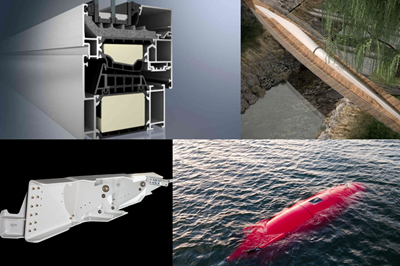

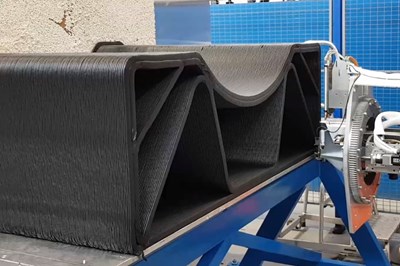

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

JEC World reveals 2022 Innovation Awards finalists

Innovation Awards celebrate successful projects and fostered cooperation between players in the composite industry, with 30 finalists in ten categories.

-

What CW's analytics have to say about 2021 composites trends

A look back on the most-read CW stories in 2021 tells us much about what to expect in 2022.

-

Top 10 CompositesWorld articles of 2021

As this year comes to a close, CompositesWorld is taking some time to reflect on what the year held for those in the composites industry. Take a look at the most popular articles of 2021.

-

Large-format, vertical, robotized, fiber-reinforced AM

MTorres joins the large-format AM fray with a system that prints vertically in lengths up to 25 meters.

-

The democratization of composites is reconfiguring supply chains

New robotic and digital technologies are enabling advanced in-house capabilities for small companies and innovative suppliers willing to embrace the move toward more affordable, sustainable composites.

-

Advancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

-

Hot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

-

IIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

-

Manuel Torres, founder and president of MTorres, dies at 82

A visionary, and entrepreneur, Manuel Torres still lives on in his founded company, which has become the focal point of research, development and innovation for high-complexity solutions in industrial process automation.

-

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

-

ZAero project update

The 2019 final review demonstrated integration of an automated CFRP process chain: AFP inline inspection and rework, cure and resin flow sensors, part performance prediction and a decision support tool for line operators.

-

Strata automates Airbus A350 inboard flap production line

With two MTorres automated tape laying (ATL) machines, the UAE-based aerostructures manufacturer plans to reduce processing times for aircraft components.

-

Grid/skin structures explained

Composites expert and veteran Stephen Tsai and automated tape and fiber placement specialist MTorres have published “Composite Double-Double and Grid/Skin Structures: Low Weight/Low Cost Design and Manufacturing,” a design and manufacturing guide for the fabrication of grid-stiffened composite structures.

-

2019 Paris Air Show: Highlights

The 2019 Paris Air Show may have lacked the glamour of a new aircraft program announcement, but the composites industry represented is clearly gearing up for next-generation aerospace manufacturing.

-

Composites industry leaders recognized at SME's AeroDef 2019

SME recently recognized Douglas D. Decker, technical fellow, Northrop Grumman and two prominent composites manufacturing companies with the 2019 Composites Manufacturing Awards.

-

Spar forming simplified

Adapting its Automated Stiffener Forming (ASF) technology to build spars directly in female molds, Northrop Grumman Innovation Systems anticipates dramatic drops in cycle time and manufacturing cost.

-

Advancing composites through virtual and augmented reality

A review of technologies that are bridging the technical divide between the virtual world of design and simulation, and the real-world of composites manufacturing and repair.

-

Infused wing sheds light on aerocomposites future

In the Irkut MS-21 infused and co-cured wings, the aerocomposites industry gets a glimpse of how out-of-autoclave technologies might be applied to primary aircraft structures.

-

Plant tour: Spirit AeroSystems, Wichita, KS

Spirit AeroSystems was an established aerospace supplier when it earned that distinction, winning the contract for the Boeing 787’s Section 41. Now its sights are set on the next generation of aircraft.

-

Plant tour: Israel Aerospace Industries, Ben Gurion International Airport, Israel

Israel Aerospace Industries (IAI) is developing increasing expertise both in and out of the autoclave as it expands an already broad composites production portfolio.

-

A complete paradigm shift in aircraft construction

With its new Torreswing automated system for mold-free, fastener-free composite fuselage and wing construction, MTorres aims to revolutionize aerostructure.

-

Building an aircraft without molds or fasteners?

MTorres has a concept (TRL 6) with which aircraft will be built with minimal hand labor, without typical molds, without metallic fasteners, and without typical stringers as they are used today.

-

Thermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

-

Zero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

-

2017 Paris Air Show is good for composites

There is definitely a lot going on this week at the Paris Air Show at Le Bourget airfield. Much of it relates to composites. Here’s a brief rundown.

-

A new paradigm in airframe construction?

MTorres, a major supplier of automated manufacturing equipment for composites, has revealed a new way to manufacture airframe structure using composites.

-

Another opportunity to meet, and learn, in Paris

At the JEC World 2017, improvements in materials and processes were present at nearly every stand, with the emphasis on automotive-capable production speeds.

-

InFactory Solutions with Airbus

Airbus spin-off supplying Industry 4.0 systems for composites completes first qualification and discusses future developments for defect position visualization.

-

Thermoplastic composite wings on the horizon?

OUTCOME, a project under the Clean Sky 2 program, aims to industrialize out-of-autoclave thermoplastic primary aerostructure.

-

JEC World: Aerospace highlights

Fokker Aerostructures BV (Hoogeveen, The Netherlands), a GKN Aerospace company, demonstrated at its stand a thermoplastic composite aircraft demonstrator spoiler, fully functional and consisting of only three parts: top skin, bottom skin and a single spar.

-

More on Spanish composites: Solution providers

My pre-JEC Europe 2016 trip through Spain yielded much fodder for future editorial content, and proved to me that the country’s composites sector is brimming with innovation.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Spanish composites: growth trajectory

I’ve been traveling through Spain and visiting composites fabricators’ facilities, and a composites fabrication equipment supplier. Entrepreneurial effort and innovation clearly can occur anywhere, and it has been a fascinating journey.

-

Dry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

-

AFP/ATL evolution: Dual-process workcells

Independent contractor and occasional CE columnist Carroll Grant draws attention to a recent phenomenon in the development of automated lamination equipment: machinery capable of operating interchangeable AFP and ATL heads.

-

Laser projection: Envisioning more than templates

Advanced systems offer ply-placement verification, aids to faster assembly and manufacturing process and quality control.

-

Plant tour: ATK Aerospace Structures, Clearfield, Utah, U.S.

High-volume, high-precision fiber and tape placement for the aerospace industry are among many specialties for this composites manufacturing behemoth.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Resin-infused MS-21 wings and wingbox

Moscow-based aeromanufacturer uses out-of-autoclave composites in attempt to leapfrog Airbus and Boeing with wider, lighter, more efficient single-aisle airliner.

-

A350 & A400M wing spars: A study in contrasts

In three short years, GKN Aerospace has taken its wing spar manufacturing strategies to new heights by dramatically reducing part weight, process complexity and production-cycle duration.

-

Paris Air Show 2013: A century of aircraft progress

Torrential rains couldn’t dampen the spirit of innovation or stop the flood of business aerospace announcements.

-

2013 JEC Europe new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

Composites automation: Trending smaller and robotic

Although AFP and automated tape laying (ATL) lamination technologies are widely used in the aircraft industry, market conditions in the past few years are driving some changes in composites equipment supplier product lines. Consultant Carroll Grant explains why.

-

The Plane in Spain

Site tours provide a rare glimpse into the Iberian Peninsula’s aerospace composites sector, with a special focus on Airbus’ activities at Illescas.

-

A350 XWB update: Smart manufacturing

Spirit AeroSystems actualizes Airbus’ intelligent design for the A350’s center fuselage and front wing spar in Kinston, N.C.

-

Q&A: Manuel Torres Martinez

At the 2011 JEC Composites Show in Paris, CT had the opportunity to interview MTorres Group chairman Manuel Torres Martinez, excerpts from which appear here.

-

Status update on composites automation

Consultant Carroll Grant reviews progress made in recent years toward greater variety in automated composites processing machine sizes configurations and capabilities.

-

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

-

GKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

Automating wind blade manufacture

Recent technology announcements portend a new era of more efficient blade production.

-

AFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

-

SAMPE Europe/JEC Composites 2009 preview

SAMPE Europe’s 30th annual spring conclave and the nearby JEC Composites Show characterize the latest in material and process technologies.

-

ATL and AFP: Signs of evolution in machine process control

Improved machine-control software, placement accuracy and design simulation have made automated fiber placement and tape laying machines truly production-worthy. The evolution, however, still continues.

-

Aviation Outlook: Fuel pricing ignites demand for composites in commercial transports

A confluence of aircraft OEM technical innovation and economic pressures on their airline customers creates increasingly favorable market conditions for aerospace composites.

-

Managing multi-axis manufacturing

Much early computer numerically controlled (CNC) machinery served short-run military and space programs where cost per part was too high to be acceptable in the manufacture of commercial aircraft. Now, Automated CNC machinery moves toward volume production and part-specific design.

-

Designing automation for productivity

Integrated, multistage work cell cuts cost and increases speed, accuracy of hole drilling on the F/A-18 E/F fighter jet's vertical stabilizer.