Alternative precursor R&D: Lignin in the lightweighting limelight

This abundant, renewable resource shows promise as an alternative to PAN for low-cost, functional carbon fibers.

Aerospace-grade carbon fiber’s remarkable properties come at a steep price, compared to steel and aluminum. That’s true, in part, because the process for converting high-performance precursor fibers into aerospace-grade structural carbon fiber is rigorous and very energy-intensive. But it is also true that production of the polyacrylonitrile (PAN) precursor fiber from which carbon fiber is made accounts for at least 50% of the final carbon fiber product. The PAN fiber itself is expensive and then there is the factor of chemical yield: it takes about 2 kg of precursor to yield, after carbonization, 1 kg of finished carbon fiber, a big contributor to carbon fiber’s high per-kilogram cost (see “The making of carbon fiber” under “Editor's Picks,” at top right). For decades, investigators have looked for less costly, yet still carbon-rich, materials that could stand in for aerospace-grade precursor, and thus enable wider use of carbon fiber in applications where the fiber’s light weight is desirable, but less-than-aerospace-grade properties would be acceptable.

Those investigations have yielded many options for usable carbon fibers, involving myriad aromatic chemistries, and hundreds of patents have been granted, dating back to the 1950s (see the Side Story titled, "What are the alternatives to PAN?" at the end of this article or click on its title under "Editor's Picks" at top right). “Alternative precursors have been looked at before, many times,” confirms Cliff Eberle, technology development manager for carbon and composites at Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US) and the director, materials and processing technology, for the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN). “But market pull and changed conditions are making it important to revisit these alternative ideas, so that we can address critical needs for expanded material choices.”

ORNL is one of several entities involved in investigating how materials other than PAN can be transmuted into usable fiber forms for lightweighting applications. It has investigated several options with numerous industry and university partners and, in concert with independent researchers in Sweden, Finland, Canada, Brazil, Australia, Korea and Japan, ORNL says that lignin holds promise.

Lots of trees = lots of lignin

Lignin is currently in the spotlight, says Eberle, because it meets key criteria. “It’s carbon-rich, it’s low in cost, the techniques exist to process it and the scale is right — there’s plenty available and it’s renewable.”

In terms of scale, “plenty” could be an understatement: As the second most abundant organic polymer on the planet, after cellulose, and the most abundant aromatic bio-polymer, lignin is found in virtually all terrestrial plants. Its complex, branched and non-linear molecules give a plant its structure: Cellulose fibers act as load-bearing elements while lignin acts as the matrix, bonding with the cellulose to create a structural bio-composite that supports the plant for upright growth. Three types of lignin monomers, sometimes called phenylpropanoids, exist, often mixed together in the same plant: cumaryl alcohol, typical of annual plants and grasses; coniferyl alcohol, found in softwood trees; and sinapyl alcohol, found mostly in hardwoods.

Lignin is obtained from pulp and paper operations, or bio-refineries. Wood chips are placed in a high-temperature solution of sodium hydroxide and sodium sulfide, called white liquor, to dissolve the lignin and separate it from cellulosic fibers. At a bio-refinery, the cellulose is used to make ethanol; at a kraft pulping plant, the cellulosic pulp goes on to become paper. The lignin-containing waste liquid, or black liquor, from either process can be burned for fuel, or processed to extract the lignin, using a precipitation process.

Precipitated lignin is dried to a powder form that must be treated. Treatment includes purification, melt-spinning or melt-blowing stabilization (in an oxidative atmosphere), and carbonization. Hardwood lignin reportedly melt-spins well but stabilizes slowly; softwood lignin is said to stabilize well but does not melt spin. These liabilities, however, could prove to be “myths” — processing limitations that can be overcome with some technical creativity. Key to the lignin fiber production process is keeping the temperature low enough to draw a fiber without crosslinking the lignin before the stabilization step.

ORNL has reported that the lignin fibers with the best mechanical properties are from softwood sources and exhibit 155 ksi strength (about one-third that of pitch fiber) and 12 Msi modulus (slightly better than E-glass). Typically, the fiber properties range much lower. “Lignin does not readily produce structural fibers, since aligned crystalline morphology doesn’t occur,” says Mark Downing, a former manager in ORNL’s Bioenergy Program.

Several investigators have looked at “doping” or mixing other polymers with lignin to improve it as a fiber precursor. One example from several years ago was Zoltek Corp.’s (St. Louis, MO, US, now part of Toray Carbon Fibers) partnership with Weyerhaeuser (Federal Way, WA, US), using US Department of Energy (DoE) funding to investigate addition of PAN polymer to lignin to increase fiber quality. The study showed that, as more PAN was added, the fiber properties improve, but the larger percentage of PAN drove costs up and the resulting hybrid fibers tended to be porous, perhaps due to immiscibility problems between the PAN and lignin during the spinning stage.

Unlocking lignin’s potential

Although there are only a handful of lignin suppliers capable of producing high-purity fiber today, interest in lignin fiber appears to be increasing, and several large pulp-and-paper companies are pursuing lignin fiber development.

Swedish forest products R&D company Innventia (Stockholm, Sweden), for one, is producing high-quality lignin carbon fibers at lab scale and demonstrating their utility in several projects. Innventia, together with Chalmers University of Technology (Gothenburg, Sweden), is known for its patented LignoBoost process, which obtains high-volume softwood lignin from black liquor, says Per Tomani, Innventia’s focus area manager of lignin and carbon fibers: “We developed a better way to extract softwood lignin, and that know-how was sold to Valmet and is now being commercialized.” Valmet (Keilasatama, Finland) has since built two lignin plants, one in Finland and a second in Plymouth, NC, US. The latter, operated by Domtar (Montreal, QC, Canada), has a projected production rate of 25,000 MT per year (see “Domtar inaugurates commercial lignin production” under “Editor's Picks”) and has expanded the availability of high-quality lignin.

Using that softwood lignin source, Tomani’s group has focused on understanding the chemistry, developing best practices for melt-spinning and fiber carbonization, and actually tailoring lignin for better fiber production: “It’s quite a different molecule, and it’s important to understand the chemistry and the processing to produce a good carbon fiber,” says Tomani.

“We’re not trying to compete with PAN,” Tomani points out. “We’re focusing on the low-cost segment of the market as an alternative to glass fiber and low-cost PAN fibers.” Although Tomani won’t reveal his group’s carbon fiber properties, he says it is producing 1K, with fiber diameters of 10-15 microns. Partner Swerea SiComp (Kista, Sweden), Sweden’s national research organization with polymer composites expertise, has woven the fibers and developed a balsa-cored structural composite panel with lignin-based carbon fiber-reinforced facesheets. Intended for lightweighting in automotive and other high-volume applications, the panel will join another demonstrator — a radio-frequency toy car (including the toy’s batteries) made with lignin-based carbon fiber — to generate interest in a full-scale lignin-fed carbon fiber line in Sweden. Says Tomani, “We hope that both industry and society will be bold enough to invest in this scale-up, for more sustainable products.”

Stora Enso (Helsinki, Finland), another pulp-and-paper giant, has investigated carbon fiber manufacture using its lignin sources. Niklas Garoff, senior development engineer at the company, reports that, unlike with PAN, desirable linearly oriented graphite domains are not formed during lignin stretching and carbonization. To rectify that, the company is researching a hybrid chemistry that combines cellulose, also derived from its pulp-and-paper activities, with lignin, in an air-gap spinning process, using an N-methylmorpholine N-oxide solution. A demonstration project has been carried out with polymer specialist Fraunhofer IAP (Pottsdam, Germany). Stora Enso believes the successful demonstration of the novel technology has high-value potential for carbon fibers.

In North America, significant research is being carried out in Canada, under the Biomaterials and Chemicals Research Network. Dubbed Lignoworks, it is one of four research networks created in 2010 as part of the Natural Sciences and Engineering Research Council of Canada’s (NSERC) Forest Sector R&D Initiative. Lignoworks participants include all of Canada’s major universities, together with industrial partners Weyerhaeuser, FPInnovations (Pointe-Claire, QC, Canada) and Alberta Pacific Forest Industries Inc. (Boyle, AB, Canada). Canada’s first commercial lignin plant, in Hinton, AB, was developed to use the LignoForce technology developed by FPInnovations to produce high-quality lignin from black liquor generated by West Fraser Timber Co.’s adjacent paper mill. Professor Frank Ko of the University of British Columbia is heading the polymeric products research efforts to convert the lignin source into carbon fiber for automotive and bio-composite applications.

Space precludes describing the many other current lignin research efforts, which range from Volkswagen’s (Wolfsburg, Germany) work on lignin-based carbon fiber for automotive body-in-white weight reduction, to university-level studies on lignin and bio-refining research work at the University of Tennessee under Dr. Art Ragauskas.

In addition to precursor potential, lignin also shows promise as a nano-material. Researchers at Florida State University, working with ORNL, have shown that, during fiber production, testing of the microstructure of individual carbon fiber samples reveals nano-scale graphitic domains embedded in an amorphous carbon matrix. The research holds promise for lignin in battery applications. Canada’s Lignoworks Polymeric Products group is investigating electrospun lignin nanofibers and carbon aerogels, which will be combined with thermoplastic polymers for composites; lignin monomers also hold potential as novel conductive polymers. Innventia also is investigating electrospinning of lignin nanofibers, information on which, says Tomani, will be revealed later this year.

Research, by the way, also continues toward a lower-cost PAN precursor. Dr. Michael Kessler, formerly of Iowa State University, who investigated lignin carbon fibers for wind blades, is now working under a State of Washington grant at Washington State University (Pullman, WA, US) to develop a route from C6 sugars derived from ligno-cellulosic bio-mass to bio-based acrylonitrile, with the goal of using that to make PAN and then carbon fiber. Funded by the DoE’s Office of Energy Efficiency and Renewable Energy (EERE), the Southern Research Institute (SRI, Birmingham, AL, US) is developing a catalytic process for conversion of sugars from non-food bio-mass to acrylonitrile, and the National Renewable Energy Laboratory (NREL, Golden, CO, US) is investigating and optimizing multiple pathways to bio-acrylonitrile, which could, similarly, step in for hydrocarbon PAN.

The potential to actual gap

All of this, however, represents potential. Marketable composites industry applications for carbon fiber produced from alternative precursors are still elusive. Commercial applications on the near horizon for lignin-based carbon fiber, thus far, are limited to one, and it is not a composite (see the Side Story titled, "First commercial use of lignin carbon fiber?" at the end of this article or click on its title under "Editor's Picks").

“We’re not fine-tuning aerospace fiber here,” cautions ORNL’s Eberle. “We’re working from the ground up on disruptive technology that can make carbon fiber more broadly available.” But Tomani points out, “There is a lot of activity occurring now on carbon fiber research, using lignin or other feedstocks. Someone will succeed.”

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRead Next

Alternative precursor R&D: What are the alternatives to PAN?

Carbon fibers made from other precursors are in use, commercially, and many more precursor alternatives have been investigated.

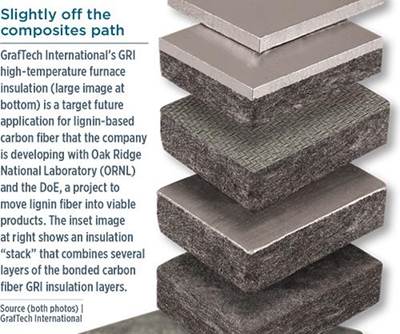

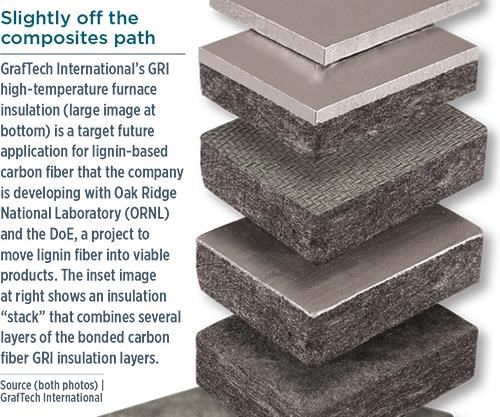

Read MoreAlternative precursor R&D: First commercial use of lignin carbon fiber?

GrafTech International (Independence, OH, US) is working with Oak Ridge National Laboratory (Oak Ridge, TN, US) and the US Department of Energy’s Advanced Manufacturing Office to develop lignin fiber manufacturing and demonstrate it in viable products.

Read MoreAlternative precursor R&D: Oak Ridge National Laboratory

Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US) has been at the forefront of North American research into alternatives to the polyacrylonitrile (PAN) precursor used to make aerospace-grade carbon fiber.

Read More

.jpg;maxWidth=300;quality=90)