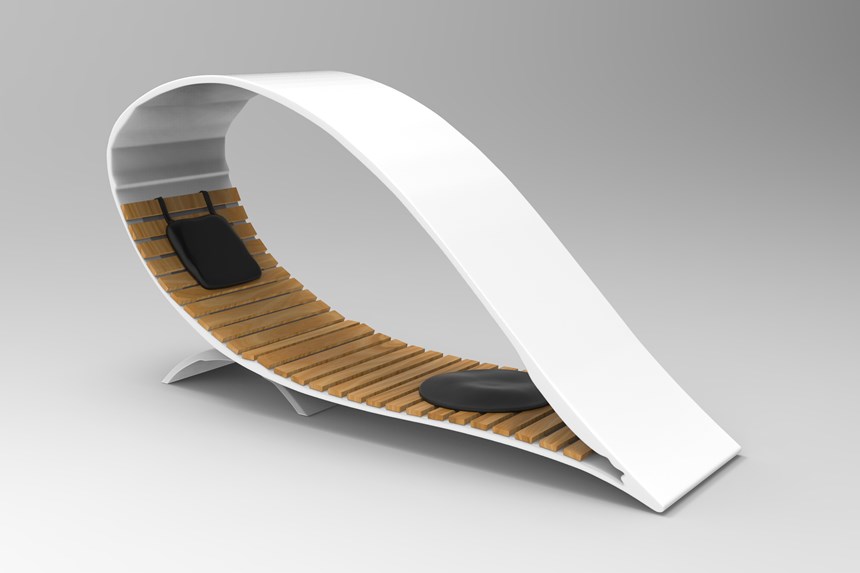

Recycling company Anmet uses decommissioned wind turbine blades as load-bearing structural supports for pedestrian bridges (shown here) and other infrastructure products. Photo Credit: Anmet

Many composites recycling methods work by burning off (pyrolysis) or chemically dissolving (solvolysis) the resins from a composite part, so that the fibers can be reclaimed and reused. Some promising recyclers and researchers are also working on methods for repurposing end-of-life (EoL) composite parts in their entirety, for a variety of reasons: for example, to retain more of the original fiber and resin’s mechanical properties, to reduce processing costs, or to reduce the carbon footprint of the recycling process. What follows are summaries of two such efforts.

Wind blade recycling: Repurposing and pyrolysis

Founded in 1998 by CEO Andrzej Adamcio, Anmet (Szprotawa, Poland) was originally started to provide manufacturing companies with solutions for metals recycling. In 2014, according to Marcin Sobczyk, product developer at Anmet, Adamcio began to recognize that there was a growing need for solutions, particularly in nearby Germany, for recycling composite wind turbine blades at the end of their life spans. Using his experience in metals recycling, Adamcio began to work on ways to recycle glass and carbon fiber composite blades, and today, wind blade recycling has become one of Anmet’s main focuses and a major area for growth going forward.

Longer-term, the company is working on the development of a pyrolysis-based solution for recovering carbon fiber from wind blades. According to Sobczyk, Anmet’s experimental furnace, tested by Wrocław University of Technology (Wrocław, Poland), has the capability of recovering carbon fibers with a strength of up to 90% that of virgin fiber, and a current capacity of processing up to 200 kilograms of carbon fiber per day. The university also tested furnace emissions, he says, working toward improvements in its filtration system.

In the immediate term, Anmet’s recycling solution involves the physical repurposing of glass fiber wind turbine blades. The company’s services start on-site: representatives will travel to a wind farm and use Anmet’s custom cutting equipment to dismantle the blade into sections, followed by transport of the parts back to the Anmet facility for reconstruction into architecture or infrastructure products.

airchitecture’s product line

According to Sobczyk, there are several environmental advantages to this type of recycling. For example, repurposing blades rather than completely deconstructing them via burning, grinding or other means expends less energy, is less costly and produces less emissions and dust.

To find creative solutions for repurposing small wind blade pieces, in 2019 Anmet hosted a student competition at the Institute of Visual Art at the University of Zielona Góra (Zielona Góra, Poland). “The results of the competition exceeded our expectations,” Sobczyk says, and were the first steps toward Anmet’s product line AIRchitecture. Distributed through partner Wings For Living UG (Dresden, Germany), which started in June 2020, the AIRchitecture brand offers a range of innovative consumer architecture products such as outdoor furniture, carports and other products using dismantled blades. Anmet has also partnered with GP Renewables Group (Warsaw, Poland) on wind blade recycling and AIRchitecture product distribution.

“As welcome as these innovations have been, they pale when compared to AIRchitecture’s most ambitious project to date: a pedestrian footbridge built from wind turbine blades,” Sobczyk says. The bridge, which will replace an aging metal bridge near Anmet’s facility, has been undergoing mechanical testing at Rzeszów University of Technology (Rzeszów, Poland), co-financed with EU funds. After final tests are completed by mid-2021, Anmet plans to begin selling the footbridges and ultimately to expand its patent globally.

Anmet recently patented these barriers built from repurposed glass fiber composite wind turbine, and is working to certify them for construction use in Europe and other markets. Photo Credit: Anmet

The company has also filed patents for other infrastructure solutions currently undergoing testing at Rzeszów University of Technology, including a fishing bridge and, most recently, geotechnical blocks for road slope strengthening. For the latter, Sobczyk says that replacing typical steel or steel-reinforced concrete road barriers with repurposed glass fiber wind blade components enables greater resistance to wear from corrosive soil environments. The composite blocks are also lighter weight, able to be reinforced with fillers as needed, and can be adapted in shape to fit the needs of a particular situation. To create the blocks, Anmet developed a specialized saw for quick, precise cutting of wind blades. So far, Anmet has built and trialed prototypes of these blocks, and is working toward registering them for construction use within the European Union, with hopes of extending into the U.S. market as well.

Looking to the future, Anmet is looking for partnerships within the U.S. and globally. In addition, with an industry partner, the company is in the planning stages of building a new facility, also in Szprotawa, called the Central European Composite Recycling Center, that it hopes to open in fall 2022.

The goal for this new facility, Sobczyk says, is to create as many composite waste conversion lines as possible. The main line will be used to sort incoming blades based on usable condition: Blade parts in good condition will be repurposed for architecture and infrastructure projects, and any damaged or otherwise unsuitable blade pieces will be sorted into a grinding or pyrolysis process. Additional production lines will be used for milling, carbon fiber pyrolysis, glass fiber pyrolysis and mechanical conversion, Sobcyzk says. Ultimately, Anmet hopes to expand to other end-use composite products beyond wind blades, as well, and to provide educational opportunities at its facility for students to learn about composites and composites recycling.

Recycling end-of-life thermoset composites: Machining and pultrusion

Similarly, over the past several years, researchers at Windesheim University of Applied Sciences (Zwolle, Netherlands) have also become aware of the need for recycling EoL composite parts, and have developed a new methodology for repurposing thermoset composite waste for new applications.

According to Dr. Ir. Albert ten Busschen, associate professor of polymer engineering at Windesheim, feasibility projects were performed in 2015 and 2016 to investigate possible technologies. From 2017-2019, a larger project was completed to prove the industrialization of the technology. This program involved partnership with more than 50 SMEs and government bodies, including resin manufacturer AOC (Zwolle) and waste management specialist SUEZ (Paris, France).

With its technology, Windesheim aims to find product solutions, like this cabinet, for recycling EoL composite parts. Photo Credit: Windesheim

The resultant technology aims to repurpose and recycle EoL composite parts such as wind turbine blades and boat hulls in their entirety, by machining them (via diamond cutting, waterjet cutting or shredding) into strips or flakes that can then be manufactured into new components using what ten Busschen calls a “push-pultrusion” process. This process, he says, was developed “to make new composite products based on reused composites in a continuous, industrial manner.”

The process, he says, is based on a traditional pultrusion process — wherein (virgin) glass fiber rovings are pulled through a resin bath and through a die to be molded into a particular part — with the addition of one more step: at the entrance of the pultrusion die, an extruder pushes a compound made up of the reused composite flakes (which contain fibers and resin) into the hollow core of the part. In this way, a thin, outer layer of virgin material is used to create the new part’s shape, filled with a reused composite core.

The composites, however, are not simply filler; according to the researchers, this method transfers the original, recycled materials’ mechanical strength, stiffness and water resistance into the new part. “It is important that the resulting parts have a sufficiently high L/D-ratio [length-to-diameter ratio] so that they can act as a new reinforcement in the new products,” ten Busschen says.

“In our technology, it is always necessary to use a virgin resin to embed the reinforcing elements and ‘glue’ them together into a new product,” he adds, though the amount of virgin versus recycled resin that is needed varies. For the researchers’ push-pultrusion technique, ten Busschen says up to 70% by weight of recycled composite can be used, with 30% virgin material. “This amount of virgin component is sufficiently low to make the method economically beneficial and have a favorably low carbon footprint,” he says.

Using this method, between 2017 and 2019, the consortium developed several full-scale demonstrators: a retaining wall, furniture, guiding beams and crane mats.

Several demonstrator products showcase the technology’s potential for consumer and infrastructure applications. Photo Credit: Windesheim

Since 2019, ten Busschen says, Windesheim researchers have begun work on a new, two-year project for the hybrid reuse of composites and other plastic waste materials. Currently, the researchers are developing prototypes of cross-ties built from reused composite train components, for the Dutch railway system, and are working with the company Save Plastics (Arnhem, Netherlands) to use recycled composites to reduce creep deformations in infrastructure products made of thermoplastic waste. In addition, pultrusion company Krafton (Heijningen, Netherlands), which was a participant in the 2017-2019 project, has adopted the technology in one of its production lines.

A cross-section of one of the demonstrator beams shows the recycled composite interior and virgin composite exterior of the part. Photo Credit: Windesheim

Two challenges faced by the consortium were potential for chemical leakage from the reused polyester in the flakes and strips, and making sure the new products were manufactured in an environmentally friendly manner. To determine if there was an issue with chemical leakage, the researchers established a test program that was carried out by independent laboratory SGS Intron (Sittard, Netherlands) to investigate the effects of leaching in the presence of groundwater or rainwater. For this program, EoL composite components from boat hulls were acquired from a scrapyard, chosen for their variety of coatings and colors, and the possible contamination of oil or diesel fuel. These materials were machined into strips and flakes and embedded into AOC’s Synolite 1967-G-9 synthetic resin in the manufacture of a new composite panel. According to the researchers, the results from SGS Intron showed that the leaching from the test panels was well below the maximum allowable limit set by the Dutch Soil Quality Decree, and EN 16637-2/NEN7375 tests for civil infrastructure projects.

A rendering of Windesheim’s push-pultrusion process, which repurposes end-of-life composite parts by extruding chopped or milled composites into the center of a new part manufactured with virgin materials via pultrusion.

Photo Credit: Windesheim

In addition, EuCIA (Brussels, Belgium) was involved in the researchers’ analysis of the new technology using EuCIA’s Eco-Calculator. “The use of this tool enabled us to quantify energy consumption and carbon footprint of products made using this technology,” ten Busschen says.

“This is a major step forward for the thermoset composites industry,” adds Dr. Jaap van der Woude from EuCIA. “Reuse of end-of-life materials has been made possible, while retaining its intrinsic properties, effectively closing the loop. Thermoset composites enable extraordinary structures like very large blades for windmills, but it can now also take responsibility for end-of-use applications.”

Related Content

Swedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreComposites-reinforced concrete for sustainable data center construction

Metromont’s C-GRID-reinforced insulated precast concrete’s high strength, durability, light weight and ease of installation improve data center performance, construction time and sustainability.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreComposites reinvent infrastructure

Celebrating National Composites Week, CW shares ways in which composites continue to evolve the way we approach infrastructure projects.

Read MoreRead Next

South Korean carbon fiber recycling start-up scales up

With plans for growth, CATACK-H claims its solvolysis-based recycling process can reclaim high-quality fibers and resins from materials and finished parts.

Read MoreCommercial-scale carbon fiber recycling comes to Tennessee

Accepting carbon fiber waste materials now, Carbon Fiber Recycling will recycle 2,000 tons of carbon fiber waste per year at its Tennessee facility.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read More

.jpg;width=70;height=70;mode=crop)

.jpg)