Antiballistics: The DARPA connection

The Defense Advanced Research Projects Agency' (DARPA) Armor Challenge taps into materials innovation at companies and by inventors who are not yet in the military procurement pipeline.

Share

The Defense Advanced Research Projects Agency (DARPA), part of the U.S. Department of Defense (DoD), launched its Armor Challenge in 2006 to tap into materials innovation at companies and by inventors who are not yet in the military procurement pipeline. Challenge participants each submit ten 18-inch square (0.46m) plates. These are subjected to ballistic testing and, should test results justify the move, new materials are selected for more detailed investigation and possible development funding by DARPA.

The latest phase in the DARPA Armor Challenge began in March 2009 will run through September 2010, and is focused on identifying promising armor concepts for military vehicles. Materials must exhibit a total areal density of less than 18 lb/ft² and be capable of stopping the 7.62-mm armor-piercing round and the 20-mm fragment-simulating projectile used in standard tests.

“The primary goal of the Armor Challenge is to improve soldier protection,” says Dr. Judah Goldwasser, program manager at the DARPA Defense Sciences Office in Arlington, Va. “Multiple solutions have been explored as submitted by the Challenge participants. We feel the program has been successful in that we’ve been able to help companies develop ideas and prove new techniques. Specifically, DARPA is exploring judicious assembly of multiple materials in a composite approach rather than the prevailing monolithic materials approach.”

He adds that the Challenge results to date indicate “hybridized materials may help us reach our goals. This includes polymer composites as well as metal and ceramic components that can extend high performance at lower weight.”

Composites Technology caught up with three DARPA Challenge participants now well immersed in applying innovative composite material and design concepts to armor products.

ARES Systems Group LLC (Vicksburg, Miss.) has 40 employees working on a Challenge effort in its Alexandria, Va. facility. Brian Ballard, ARES’ chief technology officer, says that the company manufactures EXO Scale heavy armor, which has been tested on several Grizzly-model mine-resistant, armor-protected (MRAP) vehicles, and EXO Scale LA, a light-armor variant used mostly by police agencies. The LA armor was tested in the DARPA Challenge. Both products use aramid-reinforced polymer composite outer skins that act as “frag catchers” around a unique ceramic plate.

He defines the materials function of the heavy armor as topologically controlled, in that it diffuses energy by dissipating velocity and distributing explosively formed projectile (EFP) components over wider and wider areas as the projectile moves through each layer of armor. “The overall layup takes projectile impact energy and changes it as it passes through the sequential layers of the armor,” he explains, “with each layer designed to perform a specific purpose in controlling total energy dissipation.”

The total thickness of a rigid finished panel of EXO Scale heavy armor ranges from 15 to 18 inches (0.38 to 0.46m), although Ballard points out that much of this thickness comes from air voids that allow projectile fragments to separate progressively before striking the final “stop” layer in the armor. EXO Scale LA thickness is about three inches/76 mm.

“Manufacturing of EXO Scale is very simple, and it’s easy to handle,” Ballard adds. “Panels are designed to be installed by a two-person team in the field.”

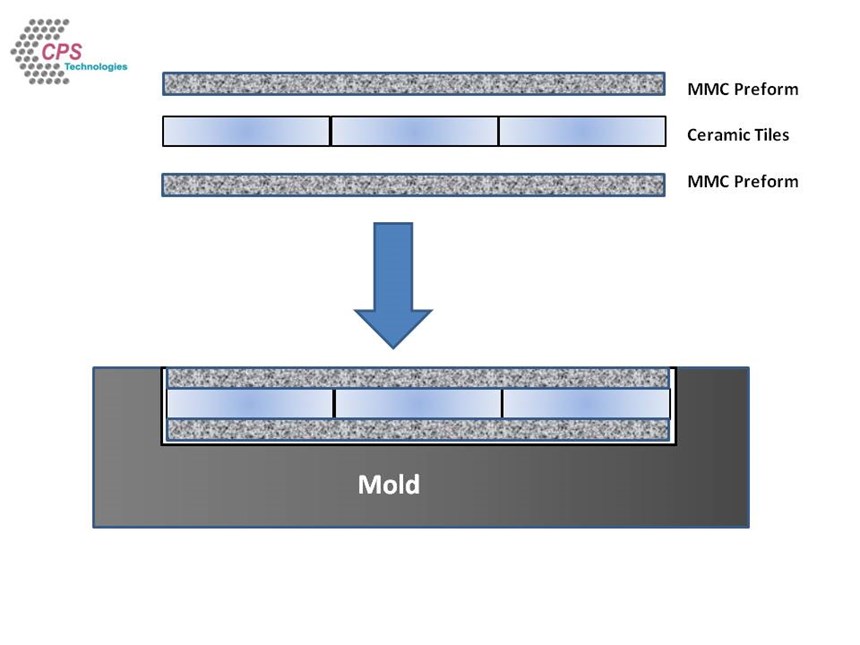

Elsewhere, HybridTech Armor is produced by CPS Technologies, with a staff of 140 based in Norton, Mass. The 2005 patent describes both ceramic particles and fibers as reinforcement in an aluminum matrix. Jim Sorensen, CPS manager of Business and Technical Development, Structural Composites, describes the current HybridTech Armor as ceramic plates or tiles encapsulated by metal-matrix composite (MMC) skins and all hermetically sealed in high-pressure cast aluminum. In short, the ceramic armor component gets tougher through the mechanical and chemical bonding of the external skins with the ceramic core.

In ballistic tests, damage from a single hit was successfully contained within a single tile, preserving the integrity of adjacent tiles. “This improves multi-hit protection,” Sorensen states, “and provides benefits for armor makers in that the modules are tough enough to be drilled or bolted like solid metal.”

Ordinarily, the use of metal, MMC and ceramic materials in a single module would raise concern about mismatched coefficients of thermal expansion (CTE). But Sorensen contends that “the different CTEs actually create residual compression in the ceramic, and more compression means better ballistic properties.”

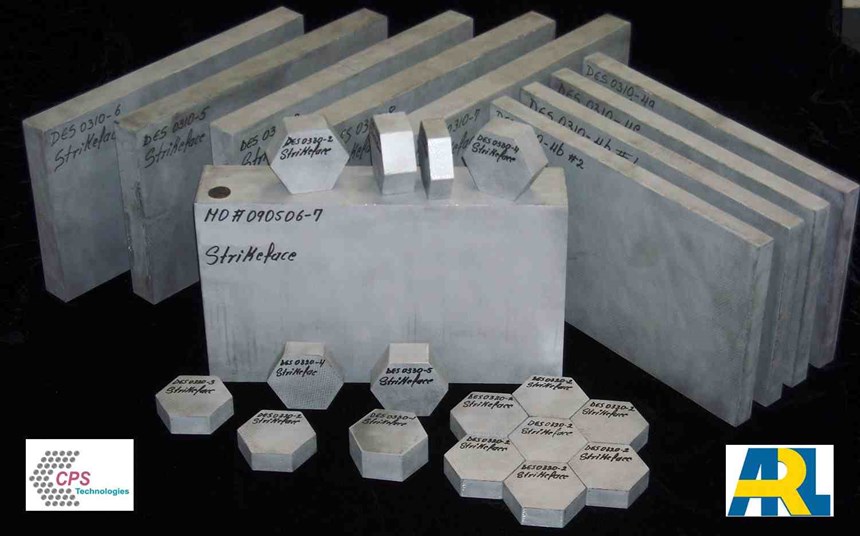

The first 4 by 4 inch (102 by 102 mm) HybridTech Armor modules were made and ballistically tested in 2006. For the DARPA Challenge in 2007, CPS Technologies made 9 by 16 inch (225 by 400 mm) modules that contained several ceramic tiles. “By succeeding in quickly manufacturing and delivering samples to DARPA for testing, we gained the confidence that HybridTech Armor was viable and manufacturable,” Sorenson says. Encouraging ballistic tests by the Army on tiles and modules led to a multiyear, multimillion-dollar cooperative agreement with U.S. Army Research Laboratory (ARL, Aberdeen Proving Ground, Md.), starting September 2008. The contract, he says, “has allowed us to refine the process and install equipment capable of making even larger modules.”

The company’s newest casting unit installed as part of the ARL contract, can make modules up to about 17 inches wide and 32 inches long (430 by 800 mm). Panel thicknesses have ranged from less than 0.5 inch to more than 4 inches (12.7 to 102 mm). An even larger casting unit is currently being fabricated for installation early next year. Initially, module sizes will be 4 ft/1.2m square, and eventually up to 4 ft by 8 ft (1.2m by 2.4m). Sorensen comments that “scaling up in size from a few inches to almost 3 ft [1m] in length has required developing assembly techniques and part handling equipment while still maintaining good integrity — meaning no shrinkage porosity in these larger modules.”

Meanwhile, in Pocomoke City, Md., Hardwire LLC has been working with DARPA since 2004 on armor developments, and participated in the first phase of the Armor Challenge. Over the past five years, the company has reported multiple technological breakthroughs, including fully automated lightweight composite military vehicle armor production, ultralightweight spall liner armor, light long-term armor strategy (LTAS)-compliant armor, and lightweight composite explosively formed projectiles (EFP) kit solutions. Further technological spin-offs from this DARPA-funded research have been deployed, such as the Hardwire’s commercial off-of the shelf (COTS) infrastructure armor, which is used to protect critical domestic infrastructure. As a result, Hardwire recently announced an expansion of its facilities that will more than double its armor production capacity.

According to John Hammond, VP of business development, Hardwire’s armor products have been used on multiple military platforms. In one recent instance, a light weight composite armor solution was provided to the U.S. Marine Corps for a mobile trauma unit built onto the back of a medium tactical vehicle replacement (MTVR) vehicle that allows a mobile surgical team to deploy in forward operating areas and provide immediate care to injured soldiers.

The company’s armor products incorporate composite materials, such as DSM Dyneema’s HMPE (high-modulus polyethylene) and Dyneema BT-10, a new and reportedly cost-effective film product. Also employed are traditional R- and S- glass, and E-glass, various metallic and other novel materials, and Hardwire’s patented steel-fiber technologies. Hammond notes that the E-glass- and steel fiber-based solutions tend to be deployed in facility and infrastructure applications where weight is less important.

Hammond reports that Hardwire pioneered the development of, and is the primary supplier of, continuously manufactured ballistic E-glass panels that are widely used by the DoD and U.S. State Department today. This product, part of the Hardwire HS armor family, was developed in 2005 with pultruder Strongwell (Bristol, Va.).

Glenn Barefoot, corporate marketing manager for Strongwell, acknowledges that “Hardwire LLC approached us about working with them to develop an E-glass ballistic panel in response to the U.S. Army Corps of Engineers’ need for UL 752 Level 3 ballistic plates to provide overhead protection of military facilities in Iraq. We jointly developed the correct resin mix and woven rovings ply laminate to consistently pass testing at that ballistic rating.” Since that initial project, the partnership has developed HS armor plates that meet both UL and NIJ specifications (see armoring chart, main story above), and range in thickness from 0.15 to 0.50 inches (3.8 to 12.7 mm).

“The production of armor panels is primarily a function of thickness,” Barefoot explains, noting that Strongwell can pultrude a panel that is 0.50 inches thick, 48 inches wide and 96 inches long (12.7 mm by 1.22m by 2.4m) at a rate of 10 to 12 inches (0.254 to 0.305m) per minute. “The resin is a proprietary blend of polyester and additives with an exotherm temperature of 350°F/177°C. There is no pressure applied other than the die pressure at the mouth of the die, which is generally between 75 and 90 psi.”

Since the initial DARPA/ARL program enabled the launch of HS armor, Hardwire and Strongwell “have provided enough composite armor to cover more than 60 acres,” Hammond claims. The HS armor has application as inserts for tents and other temporary shelters and facilities, “and we are working to develop a program to provide flexible solutions for containerized housing units (CHUs). These kinds of programs usually require high-capacity, low-unit-cost production, which was what our partnership with Strongwell set out to achieve.”

Specific to vehicle armor, Hammond believes that “given the challenges the vehicle OEMs face in designing and producing lighter-weight vehicles with no survivability compromises, highly protective and lightweight composite solutions such as our HDX family of armor will continue to be in demand. Also, our unique modular or ‘rack and stack’ design accommodates the battlefield reality of rapid component changes depending upon threat level, while also providing uniformity across vehicle platforms. The bottom line is performance: making sure that whatever you design and build provides the best chance possible to protect the men and women who rely on our armor to get them home safely.”

Related Content

Pro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More