Articulated composite booms extend reach of concrete-pumping arms

A 25% weight reduction vs. legacy steel yields economics that justify upfront cost of carbon fiber.

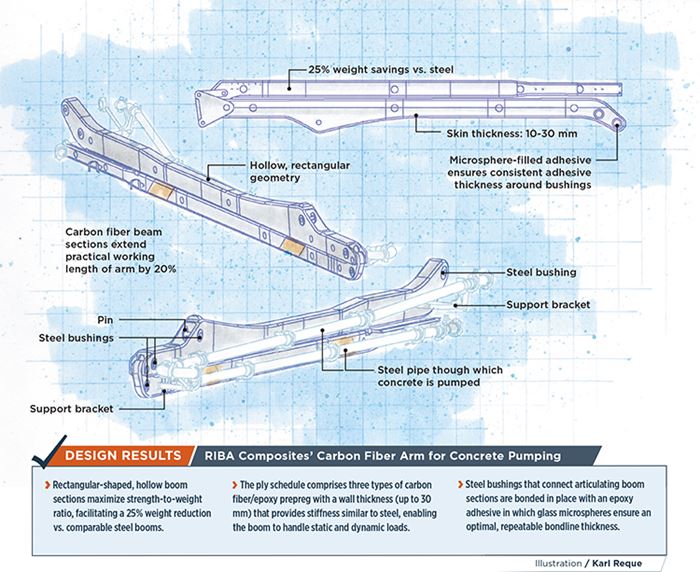

Design results:

- Rectangular-shaped, hollow boom sections maximize strength-to-weight ratio, facilitating a 25% weight reduction vs. comparable steel booms.

- The ply schedule comprises three types of carbon fiber/epoxy prepreg with a wall thickness (up to 30 mm) that provides stiffness similar to steel, enabling the boom to handle static and dynamic loads.

- Steel bushings that connect articulating boom sections are bonded in place with an epoxy adhesive in which glass microspheres ensure an optimal, repeatable bondline thickness.

As the use of composites has expanded over the past 70 years, one of their many benefits has consistently driven innovation: Composites enable manufacturers to design and build parts with the strength and stiffness of conventional materials but at significantly reduced weight. Such efforts have captured the “low-hanging fruit,” to much applause, in huge markets — aerospace, boatbuilding and wind energy come to mind. No less important, however, are efforts by pioneers in niche applications that demonstrate, with little fanfare, the unlimited potential of the technology.

Prime examples are Italian construction equipment manufacturer Centro Italiano Forniture Alberghiere Srl (CIFA, Lomazzo) and composites fabricator RIBA Composites Srl (Faenza). To- gether they have developed carbon fiber composite booms for concrete-pumping machines. In full commercial production since 2011, the booms can be made in a variety of lengths.

Cascading savings

Mounted on trucks or trailers, concrete-pumping systems typically are fitted with articulating arms made of steel, which support the steel tubing through which concrete is pumped. Depending on site accessibility and the height of the concrete pour, the arm’s end might extend hundreds of feet from the pump location. The greater the distance, the greater the moment of downward force that acts on the arm and must be counter-balanced at the truck or trailer.

RIBA’s carbon fiber booms replace the outermost segments of the arm where that force is greatest (see photo, at left) and realize section weight savings on the order of 25%. This opens the way to other benefits that justify the nominally higher cost of the carbon fiber. “The reduced weight means a smaller counterweight is needed,” says Andrea Bedeschi, RIBA’s general manager. In turn, the arm can be operated with smaller hydraulic cylinders and the entire system can be carried by a smaller, lighter truck or trailer, reducing initial investment and improving fuel economy. Additionally, a carbon boom extends the work length of the arm by as much as 20%. Finally, because scrutiny of and restrictions on truck weight are increasing, operators with oversized loads can face expensive surcharge levies or, in some countries, find themselves banned from roads. The lure of these potential benefits was the motivation for tackling the challenge of designing, making and selling a completely new part for an entirely new application.

Leveraging know-how

The chances for a commercially successful outcome to this essentially blank-slate project were bolstered by RIBA’s experience in designing and building carbon fiber spars and masts for sailboats. “We are experts in building long tube sections,” Bedeschi says. “The way we design and manufacture these booms is basically by applying the same principles for carbon fiber masts.”

To prove project feasibility, RIBA conducted FEA modeling studies, using MSC Software’s (Newport Beach, Calif.) MSC Nastran. According to Bedeschi, the effort entailed three key technical challenges, one related to design, another related to manufacturing and a third with an impact on long-term operation. A fourth challenge, market acceptance of a new paradigm in the construction industry, was mitigated, in part, by partner CIFA’s buy-in to the project once feasibility studies were completed and costs, including ROIs, were evaluated.

The key to project feasibility was designing a laminate structure with stiffness similar to the steel benchmark, a daunting challenge given that the latter has a Young’s modulus of about 207 GPa, vs. roughly 120 GPa for a PAN-based carbon/epoxy unidirectional laminate layer of the same thickness. In crude terms, this 40% stiffness deficit could be overcome by building up laminate thickness, but that would also build cost. FEA simulation enabled engineers to simultaneously assess laminate structures that would meet the stiffness criteria and explore the most cost-effective means to construct those laminates.

Each boom is subject to two primary loads: Static loads from the weight of the boom, the attached steel tubing and the concrete pumped through it; and dynamic loads generated in boom joints as the arm is moved. Simulation of both revealed that optimum boom strength-to-weight would be achieved by a hollow, rectangular geometry and a ply schedule comprising unidirectional 24K carbon fiber tape (with fibers oriented along the isostatic lines or stress trajectories), ±45° biaxial 24K carbon fiber prepreg, and ±90° woven 24K carbon fiber prepreg built up to a nominal wall thickness ranging from 10 mm up to 30 mm in high-load areas. All materials are impregnated with a toughened epoxy supplied by Saati (Legnano, Italy). The UD tapes, which account for ~50% of the laminate thickness, play a role in optimizing the structure’s bending stiffness. The ±45° biaxial prepreg and ±90° woven prepreg each comprise ~25% of the total thickness, enhancing the structure’s resistance to torque and damage respectively. RIBA sources its fabric, prepreg and fibers variously from Saati, G. Angeloni Srl (Venice, Italy), Toray Carbon Fibers Europe (Paris, France), Toho Tenax Europe GmbH (Wuppertal, Germany) and Mitsubishi Rayon Co. Ltd. (Tokyo, Japan).

The FEA study also focused on joint construction, which would require some type of pinned connection. “There was an engineering concern about this feature of the boom design because of the reduced load-bearing capacity of composites compared to metal and the potential to damage the epoxy matrix in the joint area,” Bedeschi recalls. Analysis suggested that 50-60-mm metal bushings would work if a way could be found to properly and reliably bond the metal components to the carbon/epoxy composite. Engineers devised a two-fold solution. First, to bond bushings to carbon/epoxy laminates, RIBA used Hysol epoxy adhesive, supplied by Henkel (Düsseldorf, Germany), in which the adhesive layer’s bondline is controlled by glass microspheres, the diameter of which ensures an optimum, repeatable adhesive thickness, maximizing polymerization and shear strength at the bond. Second, the laminate at the joint interface is constructed of ±45° fabric, which reportedly reduces stress in the laminate at the joint surface. Extensive testing of laminate specimens was conducted in parallel with FEA to ensure that actual mechanical properties (in particular, stiffness) correlated with the simulations.

After testing validated the computer models, RIBA received approval from CIFA to build the first commercial boom sections for a concrete-pumping machine. They replaced the final two articulating sections — roughly half the total length of a 45m mechanical arm. Each section is about 11m in length. They do not replace the initial steel sections of the arm with composites because the cost vs. benefit tradeoff favors metals. Building the entire arm with composites would be cost-prohibitive.

Boom sections are molded in female molds. During layup, overlaps of 25.4 mm to 38 mm are created between adjacent plies of prepreg, per aerospace practice. The molds are joined at the laminate overlaps, creating a hollow tube. After layup, the molds are bagged internally and externally, and the bag materials are joined at the mold’s open ends to form a single bag (see photos, at left). During autoclave cure (at 6 bar), the vacuum pulled on the bag combined with the external pressure applied by the autoclave ensures optimal consolidation and strength-to-weight ratio in the laminate, yet avoids pressure-related deformation or alteration of the mold shape. “The pressure is acting on all the surface of the bag, internally and externally,” says Deschi. “In this way we squeeze the plies without affecting the mold.”

A final challenge was curing parts with walls as thick as 30 mm. Epoxy undergoes a robust exothermic reaction — the thicker the laminate, the higher the temperature. The risk is uneven heating of the mold and laminate layers, resulting in material degradation at the center of the laminate’s through-thickness. Using a theoretical autocatalytic model, engineers predicted cure behavior as a function of temperature and devised a cure cycle with a cure temperature of 130°C and dwell steps that avoided exothermic peaks and resulted in homogeneous heating of the mold and laminate. Cycle duration, including cool down, is ~18 hours.

After cure, the demolded boom is CNC-machined on a 5-axis system, bushings are bonded into place and each section is inspected using a phased-array ultrasonic NDT system.

Since making its first 22m boom section set, RIBA’s line of booms for concrete-pumping equipment has steadily expanded. The company now makes 10 different carbon booms for concrete-pumpers with arms ranging from 25m to 101m. Widths of booms can vary from 15 to 45 cm.

Last year, RIBA produced booms for 110 arms— about 250 individual booms, and Bedeschi expects a 10% increase in sales during 2015. That the booms have quickly made inroads into an inherently conservative industry is a testament to their highly functional design and benefits.

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)