Automating swimming pool production

Small producer ramps up productivity with "entry level" robotics.

Although awe-inspiring aerospace composite programs that depend on large automated equipment get a lot of press, most composites manufacturers are small- to medium-sized, with limited resources — job shops that use hand layup or sprayup. Their owners might agree that automation would enhance productivity and reduce costs, but most are reluctant, or believe they are unable, to purchase capital equipment.

An exception is in-ground swimming pool manufacturer Ibazur (Pacage du Pessanin, France). Its parent company, Piscines Ibiza, was founded by Norbert Combes in Perpignan, France and continues to produce three hand-layed pools per day (an eight-hour shift). When demand for its pools increased in France and northern Europe, however, son Mathieu Combes looked for ways to increase production, minimize environmental impacts, save energy and reduce labor cost. The father/son team opted to build a new facility, Ibazur, in a relatively remote part of France. After determining that an automated approach was the answer, they approached Matrasur Composites (Marcoussis, France) for the solution.

Matrasur has specialized in engineering automated solutions for decades. “Automation is the key to a sustainable market development approach,” says Claude Chouet, sales manager at Matrasur and a long-time champion of improved manufacturing. Past projects include an automated resin transfer molding (RTM) line for Paris-based Matra Automobiles, a supplier to automaker Renault SA (Boulogne-Billancourt, France). The RTM line produces components for Renault’s Espace multipurpose vehicle. For Poncin Yachts (La Seyne-sur-mer, France), Matrasur developed an automated RTM machine capable of injecting more than 1 metric tonne (2,205 lb) of resin in less than 40 minutes for large boat parts.

For Ibazur, however, Matrasur prescribed an “entry-level” automated system that did not require the pool manufacturer to radically depart from its legacy production practices — the company still forms its pools on the same type of open molds it previously hand layed. But production of its largest pools has doubled. More importantly, the move to automation has proved affordable in light of the realities of the pool manufacturer’s business model and has contributed to significant improvement to the company’s bottom line.

Small shop enters the robotic age

The issue for most small composites molders, Chouet contends, is they typically offer their customers a large variety of parts, but they produce them in small quantities by hand in open molds. The limited-series production, as well as large and often awkward mold sizes and shapes, seems to work against automation. Chouet disagrees: “In fact, automation allows you to compete in the marketplace more effectively, since you can address environmental regulations and worker health and safety issues, and make open mold production ‘accessible’ so it can be done more logically.”

Chouet argues that small businesses can significantly benefit by adopting cost-effective robotic automation. Benefits include not just productivity, but also greater part consistency and quality as well as reduced environmental impact and savings, in the long run, of material and energy costs. He advocates a step-by-step approach for automation, starting with a single, affordable robot for sprayup, for instance. Then, as benefits accrue, companies can add automation for trimming, grinding, adhesive application and/or material handling. Matrasur tailors automated solutions to its customers’ requirements, and the company can supply floor, column or gantry-mounted work cells, as well as material and air-handling systems.

Chouet also advocates clustering tasks that produce volatile organic compounds (VOCs) in a contained space and having robots perform those tasks so that emissions control can be focused. This minimizes the daily quantity of air that requires treatment and, in turn, reduces the cost of the equipment and energy necessary to treat it. Further, it minimizes potential health risks for employees.

As Matrasur prepared to outfit Ibazur’s new facility, Chouet’s in-house design team conducted an audit of Ibazur’s fabrication methods, technical staff resources and skill set, then coupled that with an analysis of the desired outcome: How many parts must be produced per day? What are the quality control constraints? How is the budget limited? What are the regulatory compliance requirements?

The designers then developed a range of automated solutions, calculated the costs for each and then delivered to Ibazur a comprehensive engineering study and implementation plan specific to its new production site. Training was provided during facility build-out to ensure that Ibazur workers could operate the equipment.

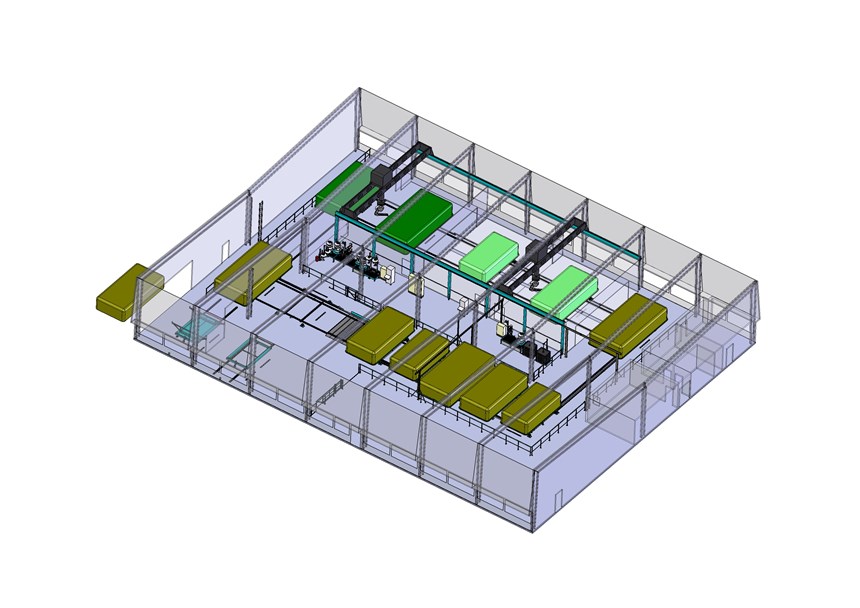

The selected plant layout, shown in the CAD rendering on p. 38, is a closed “carousel” with a moving conveyor arranged in a rectangular configuration. Designed to carry the large, unwieldy pool molds through four production steps, the carousel occupies 1,750m2 (18,800 ft2) of floor space and is equipped with two gantry-mounted robotic spraying stations complete with air collection systems, automated material supply units, a curing zone and a demolding area.

The fully automated carousel contains all of Ibazur’s pool molds in various stages of production; the molds, each marked with a radio frequency tag that allows identification by the robotic controls, stay on the conveyor and simply circulate through the process steps, without ever having to be manually moved. Says Chouet, “A forklift truck is only needed at the end of the process to remove a finished pool from a mold and transport it to the shipping area.”

The conveyor consists of two parallel tracks laid in the concrete floor with a belt drive that moves a series of “carriages,” or carts, that support the pool molds. When a carriage that is holding a mold arrives at the proper position at a production station, it triggers four pneumatic jacks, which rise up out of the floor to support the mold during that work step. When the carousel’s programmable logic controller (PLC) gives the signal to move to the next station, the carriage begins to move beneath the mold and the jacks collapse so the carriage can proceed. When the molds reach the end of the rectangular production space, a transfer mechanism enables the carriages to shift direction by 90° and move a short distance to the perpendicular tracks for transport along the short ends of the rectangle.

The first production station is an enclosed “cabin,” or work area, where the mold is prepped with release and sprayed first with gel coat and then a vinyl ester barrier coat to prevent laminate print-through and protect against blistering. The spraying is done by a Matrasur Robomat unit, the company’s entry-level automated option. The 6-axis carbon-fiber robotic arm (with a seventh axis in the gantry direction) is equipped with an automatic PROGUN gel coat application gun from Magnum Venus Plastech (MVP, Clearwater, Fla.), a key Matrasur partner supplier. The gun is modified by Matrasur engineers to work with the robotic system.

Notably, Robomat is teachable. During facility setup, the robot’s motor is released and the robot’s software is set in record mode; a technician who is skilled at spray application physically guides the robot’s arm through the spraying tasks for each pool mold (see photo in Step 4, at right). The robot encodes and stores the technician’s movements, while Matrasur’s in-house program determines the correct spray gun flow rates for each part. During production, the automated system calls up the appropriate spray program for that mold, and the robot arm goes into action, reproducing the technician’s movements at a faster rate and with greater consistency. Reteaching Robomat or adding programs for new parts is easily accomplished in a matter of minutes, says Chouet.

Air quality is maintained by an “extraction wall” along one side of the cabin (near the building’s exterior wall). Fitted with banks of multiple-speed fans, it creates a flow of air away from the robot and spray head. (Floor-mounted extraction fans are another higher-cost design option.) The fans are controlled by a styrene sensor that activates them only when sprayup is occurring, significantly reducing the amount of air collected for treatment when compared to a building-wide collection system.

After a mold is prepared and sprayed, the conveyor line moves it to the second enclosed station for lamination. Here, Ibazur employs another Robomat mounted on an overhead gantry, offering a 5m/16-ft by 5m/16-ft work envelope to accommodate the large parts. The robot arm is fitted with a modified MVP chopper gun, an automated High Volume PROGUN. The gantry design allows the robotic arm and gun to apply chopped glass and resin to one mold, then move back to the next mold in line and apply material to it, while the first mold is manually consolidated by a technician with a roller. The robot/gantry then moves forward and applies a second layer of chopped glass and resin to the rolled-out part.

Chouet explains that the robot is equipped with a sensor and safety system that prevents operation if a technician gets too close to the working zone. In this way, the rollout step can be safely performed while the robot sprays up the second mold. “For now, we’re unable to automate the rollout process,” he notes, “but it’s something we’re investigating.”

Two automated material-feed systems, also designed and built by Matrasur using MVP components, supply the robots with resins. The feed systems accommodate resin totes (some customers specify drums). The computerized system monitors the resin levels in the gun’s feed tote and pumps resin into it to ensure that the gun is adequately supplied during operation. The system includes an integral mixer and heating unit that keeps the resin consistent and at a uniform temperature. The feed can be switched readily between two sources (any combination of resins, mold releases and/or gel coats). Ibazur typically uses a polyester system, supplied by EuromereSprayCore (Chavagnes en Paillers, France) and several others sources.

At the second sprayup station, packages of multi-end glass roving sit on a pallet in the material feed area. The roving is fed through ceramic eyelets placed along the outside wall of the cabin, then it is directed to the top of the robot, just under the gantry, a distance of more than 9m/30 ft. A continuous tensioning system on the robot ensures that the roving never droops enough to become entangled with the robotic arm. Tailored for chopper guns, the roving is supplied by OCV Reinforcements (Toledo, Ohio) in extra-large packages with fewer knots, enabling production with fewer interruptions.

Long-term cost savings

After the second application of chopped glass and resin, more manual work is performed to stiffen certain pool models for handling and transport. Technicians apply preshaped kraft paper forms against the tacky layup to form reinforcing ribs, then they build a laminate over the paper with handheld chopper guns. The conveyor then moves the completely layed up molds around the corner to the curing area, where they undergo an 8- to 10-hour cure cycle (typically overnight). The last station on the carousel is for demolding. There, an overhead gantry crane lifts the completed parts off the molds and transfers them to a forklift for transport out of the building. The molds are inspected before they move around again to the mold release/gel coating station to repeat the process.

After nearly three years of operation, Ibazur reports that the number of labor hours to produce a pool has dropped from 37 to 13, saving more than €1 million ($1.44 million) in labor costs per year. And the annual energy costs have been cut in half, due primarily to lower air emission treatment costs. Raw material usage is 12 percent less, due to better part consistency and quality and less waste. So despite the initial cost of the robotic equipment and carousel, the operation is much more efficient. “There’s a huge upside here,” Chouet emphasizes. Automaton, “no matter what the business size, represents an area for vast improvement in the competitiveness of composites in all markets.”

Says Mathieu Combes, Ibazur’s owner, “We invested about €2.5 million ($3.5 million USD) in the factory and, to date, we are extremely satisfied with its performance. With six employees on site, we can produce up to seven pools per day, at a much lower cost than other facilities in France or anywhere in the world, for that matter. And, pool quality is enhanced because of the identical production process.”

Related Content

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreBabyark launches smart, composites-intensive car seat

Impact-absorbing car seat approaches safety holistically with carbon fiber and D3O materials and embedded sensors for real-time monitoring.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreToray rCF from Boeing 787 is incorporated into ultra-light laptops

Torayca-based aerospace components have successfully been repurposed into the Lenovo ThinkPad X1 Carbon Gen 12, highlighting the ongoing application of recycled composites.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)