CAMX 2016 Exhibitor Previews: Part 1

CAMX, in its third year, is growing and expanding, and the quantity and quality of new products and technologies being introduced at the show is impressive. This week features Part 1 of the CAMX 2016 Exhibitor Previews.

CAMX, in its third year, is growing and expanding, and the quantity and quality of new products and technologies being introduced at the show is impressive. CAMX Connection asked exhibitors to tell us about the products they will feature, and the response has been tremendous. This week features Part 1 of the CAMX 2016 Exhibitor Previews.

The below list includes exhibitor name, a description of the technology or product being featured and a link to additional information. The exhibit hall at CAMX features more than 550 exhibitors offering a range of products, including resins, fiber reinforcements, machinery, tooling material, software, fabrication services, training services and more.

CAMX will be held Sept. 26-29, at the Anaheim Convention Center in Anaheim, California. Exhibit floor hours are 9:30 am-5:00 pm, Tuesday, Sept. 27 and Wednesday, Sept. 28. Exhibit floor hours are 9:30 am-1:00 pm on Thursday, Sept. 29.

For more information about CAMX, including conference schedule, exhibitor list and registration, visit www.thecamx.org.

- Abaris Training Resources: NDI, engineering, manufacturing, mold fabrication, infusion and structural repair courses.

- Acrolab: Mold heating and cooling equipment.

- Agilent Technologies: Handheld Fourier transform infrared spectroscopy (FTIR) technology to analyze composites, coatings and surfaces.

- Airtech Advanced Materials: Supplies and consumables for closed molding processes.

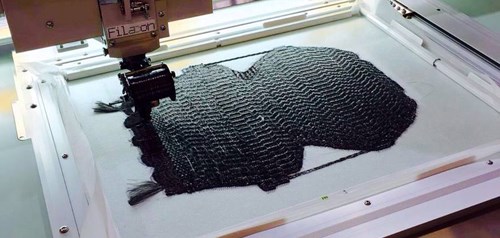

- American GFM: Semi-automated ply cutting, sequential offloading, sorting and kitting in preparation for layup.

- Armacell: PET-based core and foil products.

- A. Schulman: Forged Preg next-generation composite material.

- Ashland Performance Materials: Technical presentations on vinyl ester, low-styrne resins and fire retardants in resin and gelcoats.

- Automated Dynamics: Advanced composites fabrication, engineering, automated equipment.

- Autometrix: Cutting table demonstrations.

- Autonational Composites: Automated filament winding production systems.

- BGF Industries: Thermoplastic prepreg and carbon, glass and aramid reinforcements.

- C. A. Litzler: Thermoplastics prepreg machinery.

- Center for Integration of Composites into Infrastructure: Research and development of composite materials for infrastructure applications.

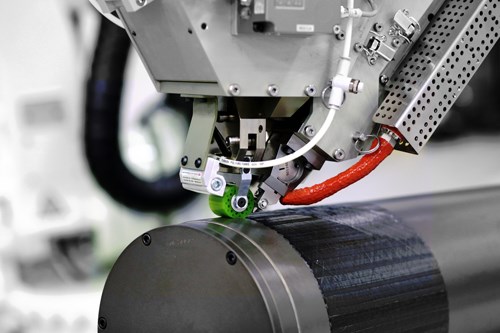

- CGTech: Machine-independent software for automated fiber and tape placement systems.

- Chem-Trend: Water-based mold release systems.

- Clayton Associates: Electric vacuum sanders for composites repair and manufacturing.

- Click Bond: Fasteners and screws for aerospace applications.

- Coastal Enterprises: High-density urethane tooling board.

- Coats: Advanced composite fibers applied to high-performance automotive parts.

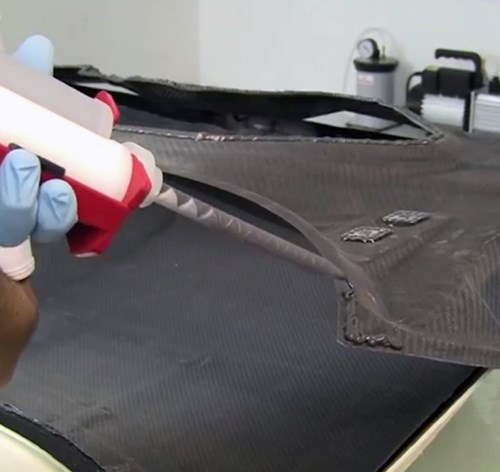

- Composites One: Live demonstrations of closed molding processes.

- C.R. Onsrud: CNC machinery and CNC control systems.

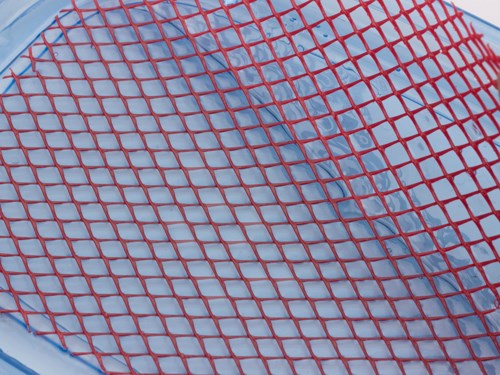

- DelStar Technologies: Naltex extruded netting flow media for infusion, RTM.

- Dia-Stron Ltd.: Automated testing systems for single fibers and filaments.

- Eastman Machine: Static cutting table systems.

- EconCore: Thermoplastic honeycomb sandwich materials.

- Elliott Co. of Indianapolis: Rigid polyiso/urethane foam core.

- Epcon Industrial Systems: Custom designed and manufactured industrial ovens and furnaces.

- General Plastics: High-temperature tooling board and foam and honeycomb core.

- Graco: Meter, mix, dispense systems for resin delivery.

- GS Manufacturing: Hand sprayup guns.

- Harper International: Advanced carbon fiber oxidation oven technology.

- Henkel: Adhesives solutions and mold releases.

- Hennecke: Processing technologies for high-pressure resin transfer molding.

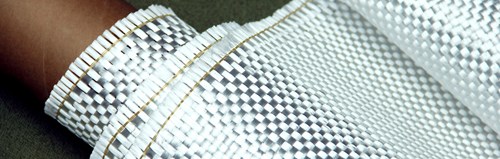

- Hexcel: Engineered core, resin systems, woven carbon fiber fabrics, multiaxial reinforcements.

- HK Research: New gelcoat series.

- Huntsman Advanced Materials: Advanced epoxy resin and polyurethane systems.

- IDI Composites International: Composites research and development technology center.

- Imetrum: Noncontact precision measurement systems.

- Innegra: Olefin-based fiber reinforcements.

- Innovative Composite Engineering: Composite tubing fabrication, complex molding services.

- Izumi: Winders, creels, warp and weft feeding, tensioning devices.

- Janicki Industries: Large-part tooling, fabrication, machining services.

- LEWCO: Batch ovens, conveyor ovens, field-assembled ovens.

- Mektech Composites: Phenolic matrix resin systems.

- Mokon: Circulating liquid temperature control systems.

- Montalvo: Web tension control systems.

- MVP: Pumping systems, spray guns, filament winding systems.

- N12 Technologies: Vertically aligned carbon nanotube sheets for interlaminar reinforcement.

- Olympus: Composites inspection solutions, including phased array wheel probe.

- Pacific Coast Composites: Advanced composites materials distribution.

- Permabond: Epoxy, acrylic and methyl methacrylate adhesives.

- Polynt Composites USA: Expanded gel coat line.

- PPG Industries: Three new glass fiber products.

- Renegade Materials/Maverick: Non-MDA polyimide high-performance resin systems.

- Technical Fibre Products: Nonwovens for thermal conductivity, FST performance, EMI shielding, structural enhancement.

- TenCate Advanced Composites: Thermoplastic unidirectional tapes, molding compounds, laminates.

- TMP: Vacuum hydraulic presses.

- Vectorply: Carbon fiber multiaxial fabrics.

- Victrex USA: Carbon fiber/PAEK unidirectional tape and laminate panels.

- Wickert USA: High-temperature contact heating presses.

- Wisconsin Oven: Electrically heated, gas-fired and indirect gas-fired composite batch curing ovens.

- Zoltek: Low-cost, industrial-grade carbon fibers.

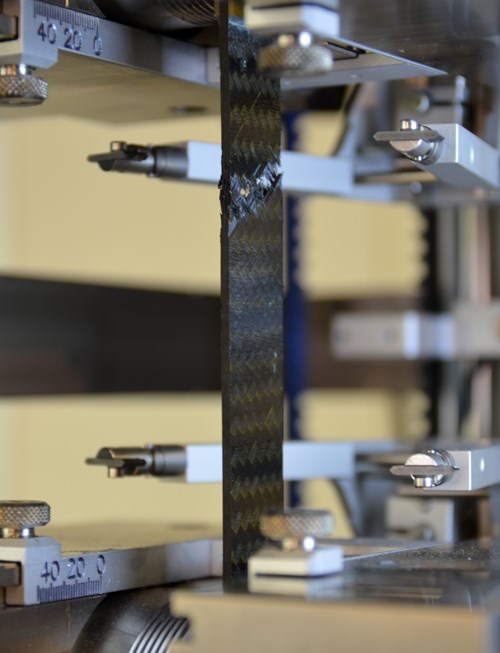

- Zwick USA: Composites testing machines.

Click here for Part 2 of CAMX previews.

Related Content

Digital chemistry platform leverages physics-based modeling for enhanced workflow

CAMX 2024: Schrödinger introduces a digital chemistry software platform, designed to enable researchers to tackle materials challenges across diverse polymer resin and carbon fiber applications.

Read MoreNet-shape machining services available for structural foam core

CAMX 2024: In addition to its distribution of various product materials for the composites industry, Technology Marketing Inc. now assists in machined net-shaped Rohacell structural foam core to customer requirements.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreCAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)