Composite Hulled Land/Sea Vehicle Nears Launch

Once the stuff of James Bond movies, this U.K.-designed amphibious automobile soon will be manufactured in North America.

A Decade of Development

Gibbs founded Gibbs Technologies in New Zealand in 1996 to explore a potential boat/car and commissioned British automotive firm Lotus to undertake an engineering viability study. When Lotus declared the concept technically feasible, initial concept work on a High-Speed Amphibious (HSA) vehicle was undertaken in 1997 by 20 engineers in Detroit, Mich. Among them was aerospace/automotive engineer Neil Jenkins, who had previously worked with automakers Rolls-Royce and Jaguar. After visiting the Gibbs team, he was so impressed that his U.K.-based design firm, Krafthaus, played a key role over the next two years in developing much of the company's current HSA technology. The result was the Aquada, a prototype that combined the look and handling of a sports car with the ability to travel more than 100 mph/160 kmh on land and 30 mph/48.3 kmh on water- fast enough to pull a water skier. Transformation from land to sea use involved simply driving into the water: The wheels automatically receded into the wheel wells, and the car became a motorboat in a process that took seconds.Jenkins then merged his business with Gibbs' to form Gibbs Technologies Ltd. UK and became managing director. At his suggestion, the company and project were relocated to Nuneaton, Warwickshire, in a corner of the U.K. that is home to Britain's famed low-volume car manufacturers and Formula 1 engineering firms.

In 2005, the company built 50 Aquadas at the new site, but none found their way to market because Gibbs' engine supplier at the time went out of business. "We didn't want to put just 50 vehicles out and then try to keep the market interested for two or three years while we found another engine supplier," explains Jenkins, now Gibbs' president and CEO. In the interim, 10 of the cars have been used in environmental testing. Says Jenkins, "This is primarily climate testing — in saltwater environments, hot and cold environments and under different road conditions." The other 40 were used in crash and durability testing and in Gibbs' marketing efforts.

Last year, after sourcing and certifying another power train, the company announced that it had cleared — enabled by more than 60 patented inventions — the most difficult hurdles in the commercialization process. The car is fully certified for crash safety and other performance standards in both Europe and North America.

Designing for Land and Water

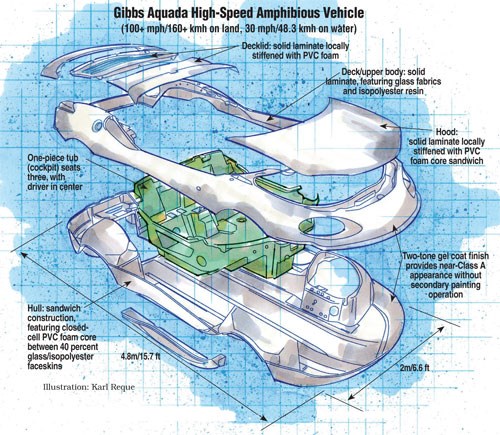

Among the many technical challenges Gibbs engineers have faced since 1997, none were more formidable than the design of the car's hull/body. "When we looked at designing a vehicle that could travel on both land and water, the first major issue was weight," says Jenkins. Unlike a typical car, the Aquada body panels would serve not only aesthetic but structural/functional purposes as well. "On land there's the consideration of load distribution through a number of fixed points," says Jenkins. "But in water, the vehicle is subject to uniform hydrodynamic pressure." Therefore body panels would have to be stronger and, by implication, heavier. He recalls that the team originally considered building it entirely out of aluminum but found that the resulting vehicle would weigh about 50 percent more than a standard car of comparable size.For these reasons, the team took a clean-slate approach to body design. Doors were eliminated to reduce potential leak points. To reduce the weight and meet performance and safety requirements in two different environments, a hybrid design was developed, consisting of an aluminum space frame, which picks up the high-density point loads, mated with a composite body that uniformly distributes marine hydrostatic pressure. This resulted in a vehicle body 30 to 40 percent stiffer than that of the typical car.

The body comprises five separate moldings: The largest and most complex is the 4.8m long by 2m wide by 0.75m deep (15.7 ft by 6.6 ft by 2.5 ft) hull/lower body, a one-piece sandwich construction, with a lightweight, closed-cell PVC foam core between glass/polyester skins. The core is preformed to part shape, using a thermoforming process developed by Gibbs' supplier Matrix Composites (Rockledge, Fla.). Mat architecture includes glass-fiber reinforcement of varying weights. Two types of high-quality, drapable stitched mats are used in areas that require extra torsional stiffness to handle the hydrodynamic loads, with a specified volume fraction (Vf) of 40 percent.

By contrast, the more lightly loaded deck/upper body is a solid laminate designed without a core to the same length and width as the hull but only 0.35m/1.2 ft deep. The fiber architecture of the solid laminate includes glass fabrics of varying weights.

The one-piece tub or "cockpit," roughly 2m wide by 1m long by 1.5m deep (6.6 ft by 3.3 ft by 4.9 ft) is a solid laminate with the exception of its floor, which is locally stiffened with a crosslinked, closed-cell foam cored sandwich construction, featuring fiber architecture similar to that used in the hull. The front and rear hatches (hood and decklid), each about 2m long by 1m wide (6.6 ft by 3.3 ft) are locally stiffened with the same foam core sandwich used in the tub.

Although Jenkins declined to provide additional details of the fiber architecture, he notes, "We looked at a number of different fibers and resins and processes, trying to find something that wasn't a big leap from current technology. We wanted materials that were readily available and commercial. The bottom line is that the molding process had to be both reliable and cost-effective." Ultimately, he says, "We worked with a local supplier to develop a customized, woven array of different thread counts and densities."

Fabricating the First Fifty

Jenkins says it took nearly five years of trial and error to perfect a reasonably reliable molding process. "When we started the process, we wanted the parts to have high strength and stiffness, a complex topology and an in-mold finish that would require no painting. We were really trying to do three things at once, which is not a good idea," he quips.In the end, the composite parts used to build the first 50 Aquadas were molded via RTM Light, using steel-backed glass-reinforced epoxy tools pulled from master models made with UREOL, a fast curing, two-part high-density polyurethane foam that exhibits no appreciable expansion when heated. Originally developed by Ciba-Geigy (Ardsley, N.Y.) , the modeling material is now marketed as RenPIM (Parts in Minutes) by Huntsman Advanced Materials (The Woodlands, Texas).

It became apparent early on, Jenkins recalls, that "with tools this large, multipoint venting and multipoint injection are the only way to distribute the resin quickly and to all areas of the mold." Gibbs used in-mold flow analysis to determine injection and venting points. "The analysis was a guide that got us 90 percent of the way there, but at some point experience takes over and provides the finesse," Jenkins reports, adding that the multiple mold vents allowed the operator to monitor resin flow-front progress.

After molds were release-prepped, a neopentyl glycol-based gel coat from Scott Bader Co. Ltd. (Wollaston, Wellingborough, Northamptonshire, U.K.) was applied to "A" surfaces- silver for the hull and red, yellow, blue, green or black for the other components. According to Jenkins, the gel coat was specially modified to cope with hazards not generally associated with boats — such as flying stones. Gibbs elected to use gel coat, in part, because setting up a conventional secondary paint line like those used by other automakers would complicate production and increase the car's cost. "In-mold color gets around both of these issues," says Jenkins, adding that because the Aquada is designed for periodic, recreational water use, there is little risk of water damage. "Osmotic blistering usually occurs when you leave a boat in the water for a year or more, so it shouldn't be an issue with the Aquada."

Achieving an automotive finish on the body panels was a particular challenge, given the high glass content (37 to 40 percent). "We didn't want fiber read-through on the A' surface," says Jenkins, noting that the team eventually achieved satisfactory results. "It's not a show car finish, but it is much better than the finish on a typical marine boat."

When the gel coat was cured, a mat composed of Rovicore (Chomarat Composites, Richdale, U.K.) was layed up on the tool's A surface. Designed for use in RTM or vacuum infusion processes, Rovicore is made from a synthetic nonwoven "core" of large fibers sandwiched between chopped glass mats. The material is mechanically stitched together (no binder), producing a conformable, flexible and compressible reinforcement. The nonwoven core serves as an integral resin distribution medium, ensuring thorough wetout of the glass fibers.

When all other reinforcements and core materials were in place (as previously noted), the mold was closed, an external vacuum was drawn and then a isophthalic polyester resin supplied by Scott Bader was injected, which circulated around the part periphery and then impregnated the fibers as it moved into the center of the mold. Cycle times for the parts are proprietary, but Jenkins reports "we have achieved a cycle time that makes the process technically and commercially viable."

Jenkins notes that isopolyester was chosen over vinyl ester because the former provided the level of high strength and high modulus necessary to ensure that the hull's sandwich laminate could withstand hydrodynamic loads.

Demolded parts were deflashed, drilled to accommodate mechanical fasteners, then cleaned and racked to await assembly. The space frame was riveted (not welded) and bonded together with an epoxy adhesive, then bonded to the hull, tub and deck with a combination of mechanical fasteners and methacrylate adhesive from ITW Plexus (Rushton, Northamptonshire, U.K.).

Preparations for Production

The Aquada is expected to go into production in 2009 for release in 2010. Jenkins says the original tools, capable of producing as many as to 1,000 parts, will be used during the entire first year of production. "Once we start up, we'll evaluate volumes," he adds. "We expect we'll eventually build tools using nickel-shell, aluminum or steel."Notably, Gibbs also has designed and plans to build the composite-hulled Quadski, a cross between an all terrain vehicle (ATV) and a personal watercraft, and is developing the Humdinga, an amphibious military vehicle, with the help of Lockheed Martin (Dallas, Texas).

"Our plans for North America are ambitious, aggressive and achievable," says Gibbs. "We'll finalize our bricks-and-mortar decisions within the next several months."

Related Content

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read More3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)