Share

Figure 1. Instron 6800 Series Universal Testing System with an environmental chamber, used for testing composites at non-ambient temperatures. Photo Credit: Instron

In Part 1 and Part 2 of this series on composites testing, I covered the types of standardized mechanical tests currently available for composite materials and recent developments in strain measurement, respectively. In the final installment of this series, I will discuss the recommended system requirements that will help you test these materials accurately and efficiently.

Testing systems for composites

Several factors need to be considered when configuring a system for testing composites (Fig. 1). First and foremost, tests need to be conducted in compliance with the appropriate standards and audit requirements. This means the system must be able to accommodate the fixtures needed for each test and meet requirements regarding specimen alignment and other factors. This includes providing the correct test environment, so that any required fixtures can operate reliably within it. Moreover, the process for changing the test setup should be simple in order to maintain high levels of productivity, and the system should be easy to use and minimize the skill level required by the operator, which reduces the likelihood of errors and optimizes productivity.

Because composite specimens can experience explosive failures, testing machines should have a high axial stiffness and be very robust to reduce and resist wear and tear from these repeatedly large shock forces. They should also have a high lateral stiffness and an accurate guidance system to maintain alignment, particularly when performing compression tests.

It is desirable to have a force measurement system (load cell and electronic signal processing) with a wide measurement range, as this eliminates the need to change the load cell when switching from high force tests (e.g., tension/compression) to low force tests (e.g., ILSS). It is also important that machine electronics are protected against the ingress of carbon fiber dust and debris, which is conductive and can damage electronics.

Test environment

The most common testing environment for composite materials is at elevated temperatures, generally in the range of 80-250°C. Specimens may be conditioned in specific environments prior to testing, typically to temperature, humidity and exposure to liquids such as water, fuel and hydraulic fluids. The time taken for polymer composite materials to achieve equilibrium with a conditioning medium is usually on the order of days or weeks, and the majority of short-duration static property testing is conducted in a chamber providing a temperature-only environment. Chambers designed for testing at low and high temperatures are generally equipped with electrical heating elements and cryogenic injection systems for cooling (usually liquid nitrogen or carbon dioxide). Mechanical cooling (refrigeration) systems are also available. Although mechanical systems generally do not provide the high cooling rates and minimum temperatures that can be achieved with cryogenic injection cooling, they are suited to providing constant temperatures for long-term tests.

Grips and fixtures

Suitable grips for composites testing include manual and hydraulic wedge grips. For demanding aerospace testing, hydraulic wedge grips are generally preferred because of their accurate alignment and repeatability. However, well-designed mechanical wedge grips can also provide acceptable alignment. For safety and reliability, hydraulic grip solutions for non-ambient testing will usually place the hydraulic components outside of the temperature chamber. In most cases, it is best to leave the grips permanently fixed in place on the test machine and use “piggyback” adapters as necessary to mount any test fixtures such as compression platens or bend fixtures onto the grips. This approach reduces the need for handling heavy items and maintains grip alignment.

Alignment

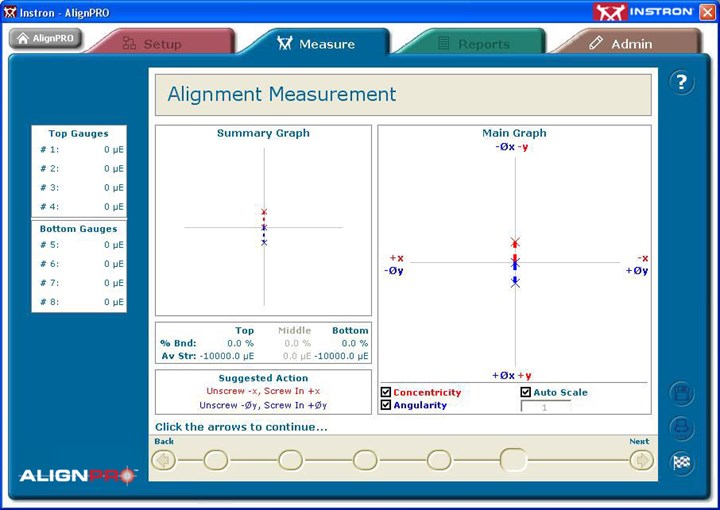

Accurate alignment is very important when testing composite materials due to the anisotropic and often brittle nature of composite specimens. Adjustable alignment fixtures are available to ensure that testing systems meet the alignment criteria required by specific audit programs used by the aerospace industry, such as Nadcap AC7122/1. To be effective, alignment fixtures need to allow adjustment of both concentricity and angularity while the machine load string is under load. The accepted method of confirming alignment is to use a strain gauged “alignment cell or specimen” to check the alignment under load. The alignment cell should have dimensions that are as close as possible to the specimens being tested. Typically, the alignment cell will be fitted with two or three groups of four strain gauges. It is possible to record the outputs of the gauges and manually calculate the bending caused by misalignment, but this is a complex and tedious process. Fortunately, software is available that provides a display of both the bending and the concentricity and angularity errors in real time (Fig. 2).

Test machine software

Software is responsible for controlling the testing machine, collecting data from the test and analyzing the data to produce test results. The latest generation of testing software is capable of all of this and much more. For instance, touchscreen technology can simplify and enhance the way in which an operator interacts with the system. Data and reports can also be exported to networks and databases, and software can integrate the system with other devices such as temperature chambers and dimensional measurement devices. Libraries of pre-configured test methods for standard composite test types are available to help simplify the management of the wide range of tests commonly encountered in a composite testing lab.

Fig. 2. Alignment software display.

Security is also an important consideration. Key elements of security are verification and validation of users, electronic signatures and traceability. Typically, verification and validation of users means regulating the access of specific individuals to different functions within the software. For example, a lab manager will be able to create and modify test methods, while an operator will have limited access to the test parameters and only be able to run methods that have already been pre-configured. Electronic signatures enable users with the appropriate rights to approve test results and documents.

It is also possible to produce audit trails of changes to methods and test results. For example, when a new version of a test standard is published and a test method is modified, this will be recorded in a file revision number along with a list of all changes.

The future of composites testing

Composites testing will continue to be driven by the development of new materials and processes and the expansion of new markets for composite materials. The mechanical testing of composite materials is complex and involves a range of test types and standards, along with the need to condition and test in a variety of environments. Integrated test systems with aligned grips, interchangeable fixtures and intuitive software with pre-configured methods will continue to make testing as easy, accurate and efficient as possible.

Related Content

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreRead Next

Composite testing challenges, Part 2: Strain measurement for the mechanical testing of composites

Recent developments in contact and noncontact strain measurement methods offer similar performance with additional benefits for composite material testing.

Read MoreComposite testing challenges, Part 1: Introduction to mechanical testing of composites

A range of standardized mechanical tests for complex composites are available and still under development for materials development, design and quality control requirements.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)