ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

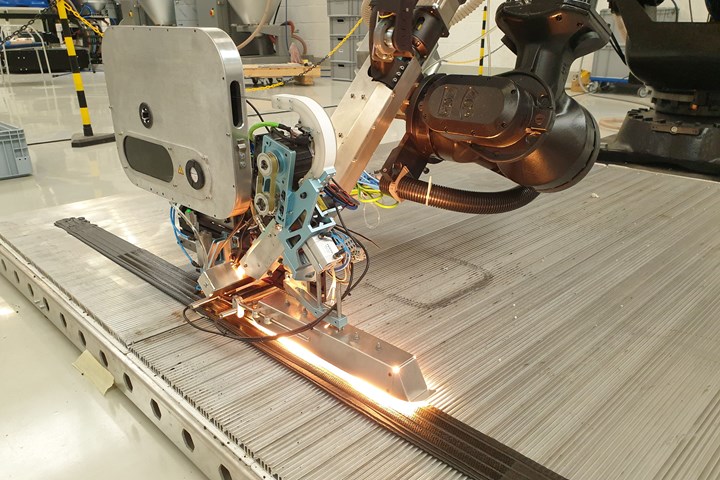

The Advanced Tape Layer Additive Manufacturing (ATLAM) printhead installed at the Technical University of Munich, Chair of Carbon Composites (LCC). Photo Credit: CEAD, TUM LCC.

The printhead for Advanced Tape Layer Additive Manufacturing (ATLAM) was recently installed at the Technical University of Munich (TUM, Germany) Chair of Carbon Composites (LCC) at their facility on the Ludwig-Bölkow-Campus in Taufkirchen, Germany. ATLAM combines continuous fiber-reinforced composite tape laying with large format additive manufacturing and was developed by CEAD (Delft, Netherlands) and GKN Aerospace (Solihull, U.K.) via their subsidiary, GKN Aerospace Deutschland GmbH (GKN Munich, Germany).

The ATLAM toolhead will be used to manufacture low-cost composite tools for aerospace applications in the research project 3DP-MAT with partners GKN Munich, machining specialist Hufschmied Zerspanungssysteme GmbH (Bobingen, Germany) and the LCC at TUM. By integrating continuous carbon fiber tapes in the extrusion-based 3D printing process, the final tools achieve a lower coefficient of thermal expansion (CTE) compared to tools printed using only short fiber reinforcement. Low CTE is crucial to comply with the tight tolerances required in the aerospace industry. In the 3DP-MAT project, Hufschmied is developing a modular clamping fixture, which will enable straightforward post-processing of printed parts with different shapes to their final tolerance. Future research with the ATLAM technology will include structural parts. The 3DP-MAT project is funded by the Bavarian State Ministry of Economic Affairs and Media, Energy and Technology.

ATLAM from CFRP flap production

Large-format additive manufacturing has evolved over the past decade. Numerous gantry- and robot-based systems with extruders of various sizes and outputs have been developed, and the technology has spread, aided by hardware and software suppliers, material specialists and end-users. CEAD is at the forefront of this technology, including robot-based 3D printing, offering a family of extruders to meet the needs of customers across various industries. CEAD extruders are designed as stand-alone systems, outputting up to 84 kilograms/hour and able to convert virtually any large robot arm into a printing system for large-volume components. CEAD’s turnkey hybrid Flexbot system is capable of both additive and subtractive manufacturing, allowing customers to deliver completed parts with desired surface finish and tolerances. Currently, there are more than 100 CEAD systems operational worldwide.

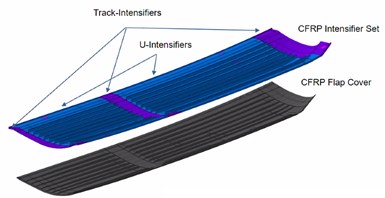

Diagram of intensifier tooling used in CFRP flap production. Photo Credit: GKN Aerospace Deutschland

GKN Munich specializes in the production of carbon fiber-reinforced polymer (CFRP) landing flaps for the Airbus family of commercial aircraft. The company began working with CEAD in 2018 to explore how to automate its production process for stringer-stiffened skins for these CFRP flaps. The process required hundreds of different composite intensifiers to form the inner side of flap covers during autoclave cure at 180°C. Intensifiers were produced using costly CFRP tooling made from prepreg materials, manually laid up on master tools that were machined from an aluminum block, one for each geometrically unique intensifier. This multi-stage process required intensive manual labor and multiple autoclave cure cycles. Thus, it was expensive with long lead times — up to several weeks with an additional 3-6 months required for production of the metal master tools.

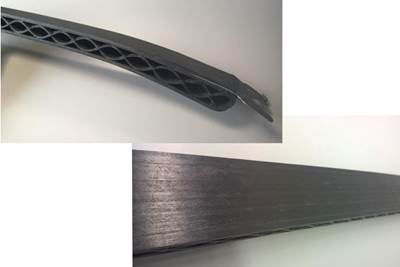

First step, high CTE

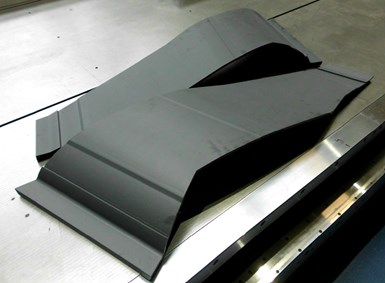

3D-printed and machined composite intensifier tools. Carbon fiber-reinforced composite, autoclave-capable tools for CFRP flap production, developed by CEAD and GKN Munich. Photo Credit: CEAD, GKN Aerospace Deutschland

In 2019, GKN aerospace and CEAD made a first attempt to replace a traditional intensifier with a 3D-printed version using a CEAD Flexbot.

The hybrid Flexbot system can 3D print the intensifier to near-net shape and the printed raw part is milled afterwards to the final contour in a second production step to achieve the required high tolerances for aerospace tooling. This process eliminates the master tool and cure cycles required when using prepreg, as well as production waste.

This first step succeeded in automating and simplifying the production of intensifiers, making it much quicker and more sustainable than the traditional process.

However, the short fiber-reinforced thermoplastics used in large 3D-printed tools (> 1.5 m) have a large thermal expansion when exposed to high-temperature autoclave cycles at 180 °C. Tooling with a high coefficient of thermal expansion (CTE) can cause dimensional variations and compromise the quality of the final part. It can also be difficult to compensate sufficiently via tool design. This forms a limitation to adopt 3D printing for large, high temperature autoclave tooling in aerospace manufacturing processes which require high tolerances in tooling and final parts.

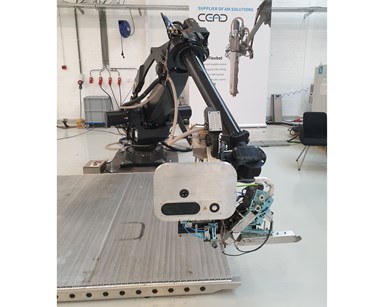

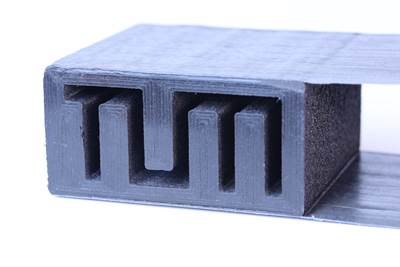

ATLAM (Advanced Tape Layer Additive Manufacturing) is a single printhead that contains a nozzle for thermoplastic extrusion and an adjacent outlet for placement of continuous fiber tape

In an attempt to overcome these challenges and harness the full potential of large-scale 3D printing, a new process needed to be developed to lower the CTE of large 3D printed autoclave tools. CEAD set out to develop a completely novel printhead that combines two existing automated processing technologies: automated tape laying and large-scale additive manufacturing pellet extrusion technology. The result is ATLAM (Advanced Tape Layer Additive Manufacturing), a single printhead that contains a nozzle for thermoplastic extrusion and an adjacent outlet for placement of impregnated continuous fiber tape that can be orientated in different directions. The layers are directly fused together by infrared (IR) heat sources that pre-heat the tape and the substrate layer before placing it on top of the extruded 3D-printed thermoplastic layer. The result is a hybrid construction of two welded layers as the printhead advances along its path.

Finally, aerospace-grade CTE

ATLAM offers versatility in part manufacturing as it allows for the local adjustment of material properties through the independent control of the extrusion nozzle and tape outlet. By changing the tape reinforcement type, width and thermoplastic matrix, ATLAM enhances the flexibility of the printing process. Tapes can be reinforced with high-performance carbon, glass and metallic fibers. The print head can process high-temperature polymers such as PESU, PEI and PEEK up to 400°C. This creates endless combinations where material properties — such as CTE, strength and stiffness — can be adjusted and tailored per application. These polymers used in ATLAM are supplied by Airtech International (Huntington Beach, Calif., U.S.) as part of its Dahltram family of high-performance additive manufacturing products.

ATLAM combines automated tape laying and and large-scale additive manufacturing pellet extrusion into a single printhead. Photo Credit: CEAD, GKN Aerospace Deutschland, TUM LCC.

ATLAM is being tested by the LCC at TUM. CTE values of ATLAM 3D-printed tools have shown a decrease of 65% in the x-direction and 70% in the y-direction when using woven prepreg tape. This is close to CTE values of traditional tools made with CFRP prepreg or Invar. In addition, the continuous fibers used by ATLAM also increase the mechanical strength and decrease material warping of large, printed parts. Test results so far show that by embedding continuous carbon fibers into the short fiber-reinforced thermoplastic material — in both the x- and y-directions — the 3D-printed tools have an unmatched low material CTE.

Reduced cost, increased sustainability

Digital design and 3D printing tools with ATLAM can reduce lead times for aerospace tooling such as intensifiers by 80%. ATLAM speeds manufacturing of tooling by 500% and cuts tooling costs by at least 50% compared to conventional Invar or CFRP tooling processes. Further cost and time savings are possible during repair of used tooling. Traditional tools require a significant amount of manual work and time to repair when they get damaged, which can happen after several use cycles. Thermoplastic materials such as PESU and PEI are very stable at high temperatures and show enhanced durability and toughness for extended use before repair is needed. 3D-printed tools also can be repaired faster by using thermoplastic welding. Alternatively, a new tool can be printed in a short time.

CEAD has worked with GKN Munich and TUM LCC to develop a 2nd generation ATLAM printhead (top). This team continues printhead testing and materials development to advance composites tooling and parts. Photo Credit: CEAD, TUM LCC

Traditional tools made of thermoset prepregs require multiple autoclave cycles, with high energy consumption. The ATLAM technology aims to eliminate the autoclave by producing tools and parts using in-situ consolidation, resulting in a reduced energy footprint. By using thermoplastic composites, energy is also saved by eliminating the need for refrigerated storage required for thermoset prepregs. Moreover, traditional CFRP prepreg tooling manufacture involves an additional master layup tool which produces a lot of waste material. ATLAM eliminates the need for a master layup tool and can print parts to near net shape, both contributing to significant waste reduction. Traditional thermoset composite materials cannot be recycled or reused. In contrast, thermoplastic 3D-printed tools can be shredded and reused for a new purpose. Overall, the ATLAM leads to savings in material, production time and energy consumption, decreasing the overall environmental footprint of tool production and use.

ATLAM offers a faster, more automated, cost-effective, durable and flexible alternative to current tooling production processes. It also provides a solution to the challenges faced by conventional 3D printing methods for producing large, high temperature autoclave tools. Thus, ATLAM removes the limits for 3D printed tools in a large portion of the composites industry.

Future development, parts

ATLAM also opens possibilities for parts beyond tooling due to the ability to embed continuous fibers to the extruded 3D-printed thermoplastic materials. This could be of interest for end-use parts where short fiber-reinforced thermoplastics alone do not offer the required strength and stiffness. This new 3D printing process will continue to be improved as further ATLAM testing and material research is completed by TUM, CEAD and GKN Munich.

For more details, visit CEAD at JEC World 2023 (April 25-27, Paris, France), Hall 5, Booth S41.

Related Content

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

3D printing and AFP join forces in automotive demonstrator

Bavarian auto industry and TU Munich research how to reduce molding costs by combining continuous fiber and 3D-printed composites.

Read MoreFuture Composite Manufacturing virtual symposium for AFP and AM

The virtual symposium, held Sept. 9-10, 2020, will focus on current state, trends and opportunities for automated fiber placement (AFP) and additive manufacturing (AM).

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More