Composite wing spars carry the enormous turboprop engines

Airbus A400M aircraft prompts new spar design and new manufacturing system designed to make it.

Design Results:

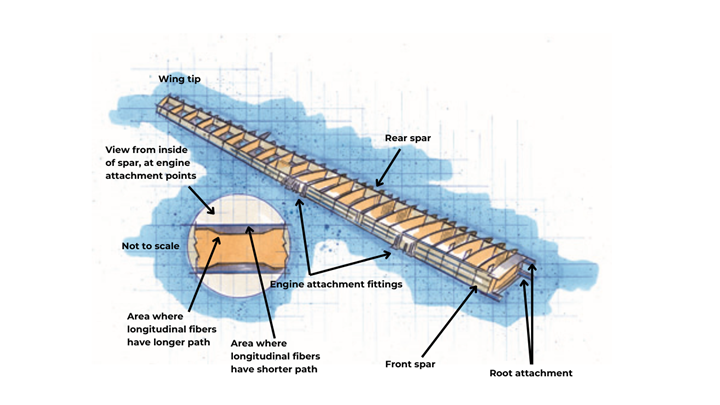

- Huge torque loads require local ply build-ups at the engine attachment points.

- C-section spar has a complex profile in the high load areas.

- Manufacturing system designed to enable high-speed tape laying in the flat, followed by double diaphragm forming of the channel-shaped spar.

Composite wing spars for large aircraft are, for all intents and purposes, new technology, having been used only twice in the past in notable but limited aircraft programs. The first instance was on Howard Hughes’ plywood-airframed H-4 Hercules Flying Boat, better known as the Spruce Goose (a composite of thin wood layers and plastic resin), which was prototyped for the U.S. military during WWII, flown once, but never placed into production. The other was the B2 Spirit stealth bomber, of which only 21 were built and placed into service for the U.S. Air Force beginning in 1993. GKN Aerospace (Cowes, Isle of Wight, U.K.) recently joined this select group as it completed the design and built the first composite components for the ~18.3m/60-ft main wing spars on Toulouse, France-based aircraft manufacturer Airbus Industries’ A400M military transport aircraft.

The A400M was conceived as a larger-sized replacement for aging C-130 Hercules and C-160 Transail military transport fleets maintained in Europe. Airbus has, thus far, fielded 192 orders for the airlifter, which is scheduled for first flight in mid-2007, with entry into service in 2009. “Soft-field” capable, the A400M is designed to take off and land on short (<1,150m/3,773 ft), unpaved runways powered by four of the Western world’s most powerful turboprop engines. Each of the A400M spars must carry all the normal flight loads for the aircraft and highly concentrated loads from the two flaps, ailerons and four spoilers. The front spars, however must carry the engine loads — the major design driver in wing spar development.

The engines drive the aircraft through the propellers by means of torque, which is reacted at the attachment points on the front spar. Each engine produces over 7,500 kW or 10,000 shp (shaft horsepower) to drive eight composite propellers per engine through a speed reduction gearbox. Each of the four sets of eight propellers, made by Ratier-Figeac (Figeac, France), weighs about 250 kg/550 lb — 1 metric ton per aircraft. The propellers, rotating at 850 rpm at take-off power, develop over 8,700 Nm (6,500 lb-ft) of torque. This torque is taken through the fittings bolted to the front spars. In general, spar web thicknesses are about 5 mm to 6 mm (about 0.2 inches) near the engine attachment points, but at the point of attachment of the engine mounting structure, the thickness of both the web and the caps is doubled to about 10 mm/0.4 inch. Similar increases in thickness occur in the vicinity of the root end where the spar is attached to the wing box. These local changes in thickness created a significant design challenge for both the structural and manufacturing engineers on the A400M program.

Designing for performance and cost

Scheduled for entry into service in 2009, the A400M will replace aging C-130 Hercules and C-160 Transail military transport fleets in Europe. GKN’s composite spars will handle all wing aeroloads as well as torque overloads from four of the Western World’s most powerful turboprop engines.

Photo Credit: Airbus

One of the main criteria in any modern aircraft program is designing to a tight cost target. In this case, it meant creating a spar design that could be produced by an automated process and then designing a manufacturing system able to make such a large, complex part to the exacting quality standards needed for such a heavily loaded piece of primary structure.

Phil Grainger, GKN Aerospace’s technical director and chief technologist, explains that building such a large part manually, as was done on early A400M spars, is slow, with typically a 0.75kg/hr (1.5 lb/hr) lay down rate. However, during serial production, the part will be layed up flat, using an automated tape layer (ATL) and subsequently hot drape formed into the C-section shape. At this point, layup rates of 25 kg/hr (50 lb/hr) will be achievable. Grainger emphasizes that these are achievable average rates over a shift, on real parts.

Figure 1, Photo Credit: GKN Aerospace

To automate the process, GKN Aerospace has invested in a large ATL with a 20m/63-ft bed (figure 1), manufactured by MTorres (Navarra, Spain). The ATL is able to lay the complex preforms in their developed shapes from unidirectional prepreg, using a 977-2 carbon fiber/toughened epoxy uni tape supplied by Cytec Engineered Materials Ltd. (Wrexham, U.K.). To form the C-section, the preform will be moved from the tape layer to a hot drape former provided by equipment manufacturer Aeroform Ltd. (Poole, Dorset, U.K.).

Photo Credit: GKN Aerospace

To facilitate pulling a vacuum, the layup will be sandwiched between two diaphragms made from Kapton polyimide film, supplied by DuPont Electronic Technologies (Circleville, Ohio). The space between the films will be evacuated and then infrared heating will be applied from above the part to raise the temperature to 60°C/140°F over a period of one hour. This ensures that even the material at the center of the thickest section at the root end is warmed uniformly to the same temperature. Pressure then will be gently applied to form the laminate, constrained by the two diaphragms over a lightweight tool that accurately represents the inside surface of the spar. This C-forming process is achieved very slowly over a period of 20 minutes. (After forming, the Kapton films are discarded.)

The challenge in designing this process has been that the path length (see drawing, first image at right) of the longitudinal fibers in the caps, in the extra material added at the engine attachment reinforcements, is greater than in the rest of the spar. In most processes, this would cause wrinkling, creating unacceptable degradation of the properties in the most critical part of the spar. However, Grainger reports the gentle, processive force achieved in the process permits intra-ply slippage, which enables the material with the shorter path lengths to be extruded from the ends of the spar.

After the drape former finishes forming the spar over the tool, the layup will be transferred to a second male mold, made from Invar. When the spar is in place, a sacrificial layer of woven material, the purpose of which is explained below, will be hand layed in a few critical areas. The spars then will be cured conventionally in an autoclave.

The spars are made in two sections per wing. The front spar is divided into two parts of 12m/39 ft and 7m/23 ft and the rear spar parts are 14m/45 ft and 5m/16 ft. The joining plates used between the two parts of each spar also are composite C-channels, placed on the inside and outside of the joint and secured with fasteners. Because the fit between the spar and the joining plates has to be accurate within 0.25 mm/0.01 inches, the spar is machined locally in the areas where the sacrificial layers have been placed. In common practice, such joints would be made with metal joining plates, but GKN believes that using composites not only saves weight but also reduces the potential for thermal stress and corrosion.

The need to machine a 14m/45-ft long spar created an additional design challenge because of the different coefficients of thermal expansion (CTE) between the part and the machine bed, which is made from steel. The bed CTE is high (12 x 10-6/°C or 6.6 x 10-6/°F); the carbon composite spar’s CTE is near zero. The conventional solution for ensuring that the spars are the same length regardless of the ambient temperature is to operate the machine tool in an air-conditioned enclosure. GKN Aerospace had a smarter idea. Working with the University of Huddersfield (Queensgate, Huddersfield, U.K.), GKN developed software that senses the temperature of the machine bed, the ambient shop environment and the air immediately surrounding the component. It then calculates a correction to the instructions the software sends to the cutting head, enabling the machine to achieve dimensional accuracy in the part regardless of the temperature differences. Since this solution permits the machining to be performed without the special air-conditioning equipment, this approach is expected not only to eliminate a portion of the capital investment but reduce energy cost for the life of the program.

According to GKN, the automated process will be able to produce a 14m/45 ft section of spar in 24 hours, rather than the six to eight days required for conventional hand layup.

Prepreg vs. resin film infusion

Many in the aerospace industry were surprised that Airbus and GKN Aerospace had taken the decision to make this spar from conventional prepreg. GKN Aerospace is well known for its pioneering work on the ALCAS (European Union composite development program), during which it has built spars using noncrimp fabrics by means of the resin film infusion (RFI) process. Grainger explains that for the A400M, the customer needed a low-risk program that could be completed within a short timeframe. However, he does not rule out the use of RFI and textile technology in future wing spars, particularly where cost is a prime driver.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)