IBEX 2017 show report

Increased attendance and exhibitors despite Irma, continued delivery of latest in composite technologies for marine industry.

The International BoatBuilders’ Exhibition and Conference (IBEX, Sep. 19-21, Tampa, FL, US) continues to be the major US event for composites in the marine industry. Despite Hurricane Irma hitting Florida the week before, IBEX still posted a 4% increase in attendees and 10% increase in exhibitors. Thankfully, the Tampa area was mostly spared of serious impact. However, a special session on hurricane recovery was hosted and a donation was made to the Feeding Tampa Bay organization.

For those wanting to learn more about composites, there were a variety of opportunities including educational workshops and seminars (see below) as well as the hands-on Future Materials area within the Composites Pavilion in the 3rd floor exhibit hall.

SEMINARS

- Hand layup essentials

- Engineering Live! (composite engineers solve actual problems on demand)

- Repairing infused composites

- Shop floor testing

- Transom engineering

- When weight matters

- Are your datasheets telling you the truth?

- Avoiding composites manufacturing flaws

- Life cycle and the future of the marine industry

- Designing boats for a new generation of diesel outboards

- Bionic lightweight design

WORKSHOPS and SUPER SESSIONS

- Fiberglass boat repair by West System

- Core College by DIAB

- Workforce training videos for gelcoat application by Ashland

- How sandwich construction can make your products more sustainable by DIAB

- Composite Process Review (CPR) for the marine manufacturer by Composites One

- Flow model simulation for vacuum infusion by Composites Consulting Group

|

IBEX 2017 Future Materials exhibit. SOURCE: CompositesWorld.

This was the third year for Future Materials, which is produced jointly by the IBEX show, CompositesWorld and Professional BoatBuilder magazine. It featured a variety of composite materials and process technologies for attendees to view, pick up and investigate, including 3D printed autoclave-capable molds, 3D printed composite parts, infusion repair kits, natural fibers and spread-tow carbon fibers, processing aids, new core materials, new sources/distributors for materials and processing aids, thermoplastic epoxy adhesive, improved-impact resistance resins, and solutions for improved sustainability and recycling. Check out the videos and connect to more info at the CW Future Materials knowledge center.

|

|

|

|

Highlights from seminars

I attended the fantastic seminar on Life Cycle and the Future of the Marine Industry, which featured Ann Avary, who is leading various recycling programs at the NW Center of Excellence for Marine Manufacturing & Technology at Skagit Valley College (Anacortes, WA, US); Dr. Brian Pillay at the University of Alabama Birmingham’s (UAB) Materials and Applications Development Center (MPAD) for composites, Desi Banatao from recyclable epoxy resin supplier Connora Technologies (Hayward, CA, US) and longtime boatbuilder Michael Reardon, who, as founder of Daedalus Yachts (Edenton, NC, US), is building an 80-ft carbon fiber composite foiling catamaran, which will enable fully-automated sailing around the world with minimal crew and no fossil fuels. Instead, the D80 will rely on a hybrid system featuring the Torqueedo Deep Blue Hybrid electric propulsion and power management system, solar panels, wind turbines, lithium batteries and hydrogen fuel cells.

his seminar was a great combination of speakers and audience participation. Pillay provided a lot of practical data (e.g., landfill costs and cost increases) thanks to his studies on composites recycling and life cycle costs. Banatao discussed real-world programs that Connora has established with sporting goods manufacturers like Burton Snowboards (Burlington, VT, US), using their Recyclamine hardener for epoxy resins that enables prepreg, manufacturing waste and end-of-life products to be recycled with hot acetic acid, recovering fabrics with weave intact and thermoplastic epoxy that can then be thermoformed or injection molded (e.g., snowboard bindings, surfboard fins, goggle frames) for near-zero landfill manufacturing. Reardon wrapped up by describing why the D80 was envisioned to be sustainable and how Daedalus Yachts will achieve this, challenging the industry to begin working together to find solutions for reducing manufacturing waste, making boats more environmentally friendly (no fossil fuels) and recycling/repurposing end-of-life and post-damage abandoned boats.

Connora Technologies is working with companies to recycle composite waste into new products for near-zero landfill manufacturing.

SOURCE: Connora.

This last point was discussed poignantly by audience members. A native of the Bahamas asked how her country should deal with all of the composite boats abandoned there after storms and the end of their useful life? A technician from Horizon Yachts (Taiwan) then suggested that if the industry is indeed building boats to be high-quality “houses” on the water that last for many decades, is it not possible to repurpose abandoned, damaged and end-of-life boats as houses for locations around the world currently facing a housing crisis?

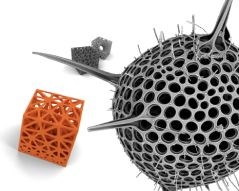

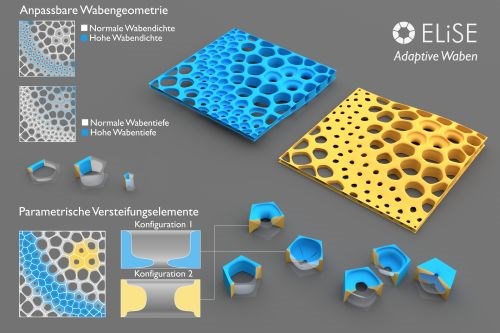

Another excellent seminar was presented by David Leidenfrost from the Bionic Lightweight Design department at the Alfred Wegener Institute (AWI, Bremerhaven, Germany). He showed how lessons learned from highly efficient structures in nature — for example, bone, trees and in the case of AWI, thousands of different types of marine plankton — can provide structural principles that can be applied to reduce weight by up to 70% in structures like boat stringers, automotive B-pillars and bike frames. He discussed concepts like asymmetrically radiussed joints and automated stiffening of shells and volumes where the size and geometry of each cell is tailored according to load — e.g., smaller, more closed cells where the load is greatest morphing into larger, more open cells where there loading in minimal.

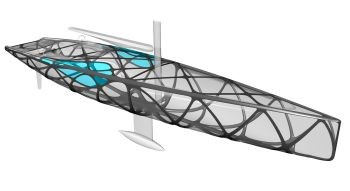

The EXO concept yacht’s structure was developed to solve the problem of how to maintain lightweight in a high-performance 46m sailing yacht when the region of highest load (mast, keel) also includes 63 m2 of glass windows. SOURCE: Dykstra Naval Architects. |

ELiSE is a systematic design process which uses nature’s optimized structures in plankton to help optimize marine, automotive and other structures for strength, stiffness and lightweight. SOURCE: ELiSE |

ELiSE has developed automated stiffening of shells and volumes where the size and geometry of each cell is tailored according to load — e.g., smaller, more closed cells where the load is greatest morphing into larger, more open cells where there loading in minimal. SOURCE: David Leidenfrost, ELiSE and AWI.

The audience discussed how with continued development in 3D printing, this bionic design is indeed the future for efficient, lightweight structures. But Leidenfrost pointed out that because the manufacturing process is considered early on in the ELiSE bionic product development process, more traditional methods can be used as well. For example, the organic-looking structure of the EXO concept yacht could be simplified as traditional top-hat stringers following the most advantageous load paths and fabricated using hand layup.

IBEX 2018 will once again be held in Tampa from October 2-4. If you’re involved in marine composites, we hope to see you there!

And if you have ideas for materials or technologies that we should include in the 2018 Future Materials exhibit, please e-mail me: ginger@compositesworld.com

Related Content

REGENT progresses seaglider prototype development, prepares for crewed testing

All-electric composites-intensive maritime craft will enhance coastal transportation capabilities by mid-decade.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreAlliance for European Flax-Linen and Hemp reports increasing flax fiber adoption in marine

The natural fiber is increasing traction across several marine applications, including in projects by Greenboats, Northern Light Composites, the Beneteau Group and others.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)