Impact Delamination Reduction of Multiaxial Carbon Fiber Composites Using Interleaved “Micromesh™” Polyamide Veils

Learn about how excessive damage due to impact events can severely limit the use of carbon fiber composites in high performance applications.

Excessive damage due to impact events can severely limit the use of carbon fiber composites in high performance applications. Use of lower cost, “non-toughened” matrix resin systems and out-of autoclave (OOA) processes can further reduce damage tolerance due to increased brittleness and variability within the composite. In order to overcome these obstacles Vectorply Corporation provides interlaminar toughened reinforcement fabrics utilizing extremely lightweight (6gsm) polyamide veil, called “Micromesh™”.

To demonstrate the increase in damage tolerance, several vacuum infused laminates using Vectorply VectorUltra™ reinforcements and vinyl ester resin were first impacted according to the ASTM D7136 test method, and then c-scanned to determine the extent of damage.

Composite Laminate Details

| Fabric Type | Fabric Nomenclature | Fabric A/W (g/m2) | Laminate Schedule | Fabrication Process | Matrix Resin |

| +45°/-45° | C-BX 0450 | 150 | [+45°/-45°]10S | Vacuum Infustion Processing (VIP) |

CCP Composites STYPOL® RF1001L-00 vinyl ester |

| +45°/-45° w/Micromesh™ | C-BXi 0456 | 156 | [MM/+45°/MM/-45°/MM]10S | ||

| +45°/-45° | C-BX 1200 | 400 | [+45°/-45°]6S | ||

| +45°/-45° | C-BXI 1206 | 406 | [MM/+45°/MM/-45°/MM]6S |

Impact Test Details

Test Method – ASTM D7136 “Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event”

| - Laminate Specimen Size: | 102mm x 102mm |

| - Impactor Mass: | 2.4kg (plate mass only) |

| - Impactor Drop Height: | 448mm |

| - Impact Velocity: | 2.96m/sec |

| - Impact Energy: | 12 Joules |

Delaminated Area Comparison

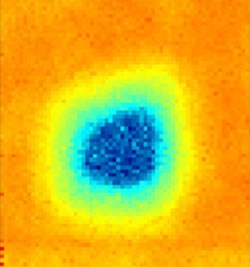

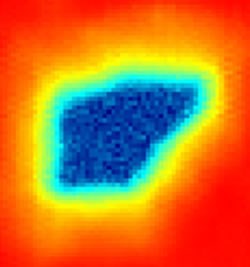

From the c-scan results (see sample Figures 1 and 2 below), the delaminated areas (blue-dark blue) were measured and compared. By including the Micromesh™ veils, a decrease in delaminated area of 43% and 33% was seen compared to the C-BX 0450 and C-BX 1200 control laminates respectively.

Figure 1: Impacted C-BXi 0456 |

Figure 2: Impacted C-BX 0450 |

More on Vectorply VectorUltra products