Increasing the composite stack: Co-molding of dissimilar materials

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. (Sponsored)

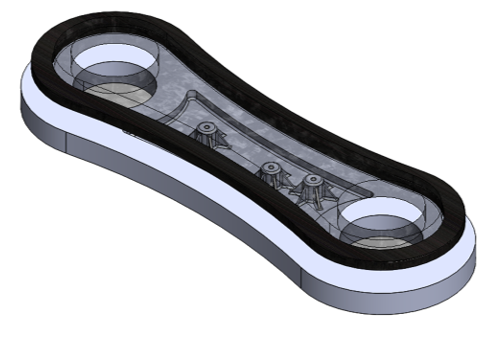

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. This overview is for those who are unfamiliar with thermoset materials and their molding processes. During this presentation, LyondellBasell will review the functional elements of composite materials and defining the types of challenges that co-molding can solve based on their size relative to the finished part. They will also discuss the use of metal inserts, including design concerns and material selection, along with more advanced concepts in the co-molding of different molding compounds and the use of additional filler bodies.

For more information on this and other LyondellBasell products, visit LyondellBasell.com and follow them online on Facebook, Twitter, and LinkedIn.

Related Content

-

Proper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

.jpg;maxWidth=300;quality=90)