Issues With Design

Though steel is the traditional material for coiled tubing because of its low price, it is susceptible to corrosion, fatigue failure (caused by repeated coiling and uncoiling), and troublesome joints. In larger sizes, its weight can increase transport difficulties. With the advent of secondary recovery methods

Though steel is the traditional material for coiled tubing because of its low price, it is susceptible to corrosion, fatigue failure (caused by repeated coiling and uncoiling), and troublesome joints. In larger sizes, its weight can increase transport difficulties. With the advent of secondary recovery methods, where water or gases are injected back into the formation to enhance oil recovery, there was an increasing need for corrosion-resistant line pipe and downhole tubing. The concept of continuous composite piping was envisioned and independently produced by Jay Carter, Brandt Goldsworthy and Ciba-Geigy in the late 1960s and early 1970s. A push for viable spoolable product originated at Conoco in the mid-1980s, reports Fiberspar Corp. (West Wareham, Mass., U.S.A.) president Peter Quigley. “ We were approached by DuPont and Conoco in 1993 and entered into a two-year joint project to develop a spoolable product,” says Quigley. In 1995, a full-scale trial was conducted in a Halliburton test well, and Fiberspar acquired Conoco’s patents in 1996. Simultaneously, Hydril Co. LP (Houston) and ABB Offshore Systems AS (Billingstad, Norway) were developing their own versions of the spoolable concept (in connection with other joint industry projects) for both onshore and offshore applications.

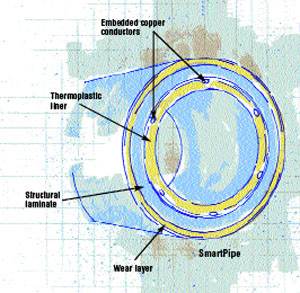

Today, bonded spoolable composite tubing features a thermoplastic liner overwrapped with a structural laminate of carbon or glass fibers in an epoxy thermoset matrix, which is commonly covered with a thermoplastic or sacrificial glass fiber/ thermoset wear layer. While steel spoolable pipe and bonded composite spoolable pipe can be spooled to about the same strain, the composite product has superior bending cyclic fatigue resistance, says Quigley. Bonded spoolable pipe is manufactured by extruding the thermoplastic liner in the appropriate size and, in some cases, pressurizing the liner with hot water or air to an internal pressure of between 50 and 200 psi/3.5 to 14 bar. The liner is a moving production mandrel, as glass or carbon fibers wet out with thermoset resin are wound around it in a helical fashion.Winding heads in an orbital process analogous to filament winding. In contrast to typical composite design, where fibers are aligned with principal stress directions, composite spoolable pipe fiber ply angles must be off-axis to allow spooling.

The composite is cured on the fly, and an outer thermoplastic wear layer may be added to the pipe, post cure. Production rates are typically on the order of 10 ft/min to form lengths of many thousands of feet for some applications. Fiberspar has patented composite spoolable pipe with built-in power and data cables. They are embedded in the thermoplastic liner to create an advanced “smart” drilling system that can monitor the health and productivity of a well bore and help optimize reservoir production.

Unbonded flexible pipe, commercially available for decades and qualified for offshore service, is probably the best known of the unbonded spoolable tubulars. It is made up of an inner thermoplastic barrier layer, multiple helically wound metallic armor layers for hoop and axial strength, and an outer thermoplastic barrier sheath. While not a composite, as defined in this publication, metal-armored flexible pipe has made great strides in deep-water applications.

Manufacturers include Coflexip Stena Offshore (CSO, Le Trait, France), Deepflex (Houston), NKT Offshore (Broendby, Denmark) and Wellstream (a Halliburton company, Houston and Newcastle upon Tyne, U.K.). All four are researching composite replacements for steel armor layers, to reduce weight and enhance corrosion resistance. CSO and Wellstream already offer pipe structures with axial carbon fiber composite strips, and Deepflex is developing and commercializing an all-composite, unbonded flexible pipe.

Reinforced thermoplastic pipe (RTP), a simpler variation of unbonded flexible pipe, consists of just three layers: a thermoplastic liner; a reinforcing layer of aramid (although fiberglass or carbon are sometimes used), which may be embedded in thermoplastic matrix or simply dry wound; and an outer thermoplastic wear layer. Here, too, the extruded thermoplastic liner acts as both a pressure/fluid barrier and a manufacturing mandrel on which the reinforcing laminate layers are placed. Diameters range from 3 to 10 inches (ID) with pressure ratings from 650 to 2,600 psi/45 to 180 bar. Suppliers include Wellstream, Pipelife Nederland BV (Enkhuizen, The Netherlands) and Tubes d’Aquitaine (Salaunes, France, recently acquired by Wellstream). A major difference between RTP and other composite coiled tubing is RTP’s capacity for higher bending strain. Axial fiber strains of about 8 percent are common, roughly the same as that for unbonded flexible pipe.

Finally, smaller-diameter bonded flexible pipes are manufactured by Phoenix Rubber Industrial Ltd. (Budapest, Hungary) and Manuli Rubber SpA (Milan, Italy) for specific applications, such as loading/unloading lines and jumpers. In bonded pipe construction, elastomeric materials are heated and vulcanized or bonded together with the metallic armor layers. Bonded flexibles have excellent fatigue characteristics, and bonding the layers together creates more stable metallic end fittings, says Adam Jackson of Thermotite AS (Orkanger, Norway).

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreRead Next

Spoolable Composite Tubulars

A new generation of spoolable piping offers fatigue resistance and lower life cycle costs.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)