JEC World 2019: Hexcel

Hexcel held its annual press conference at JEC World 2019 and reported promising numbers, as well as several new products and technologies.

Hexcel (Stamford, Conn., U.S.) held its annual press conference at JEC World 2019 and reported promising numbers. The company had 2018 sales of $2.2 billion, with 48 percent of that coming from the U.S., 48 percent from Europe and 4 percent from other regions. The company enjoyed 10 percent growth in 2018 and expects similar in 2019. In aerospace, the Airbus A350 and Airbus A320 neo are the most important aircraft programs on the company’s books, with the former consuming $4.8 million in Hexcel materials per shipset, and the latter consuming $450,000 in Hexcel materials per shipset. In the last 18 months Hexcel opened its new engineered core plant in Casablanca, Morocco, and a new $250 million polyacrylonitrile (PAN)/carbon fiber plant in Roussilon, France. Early this year Hexcel will open an R&T center in Les Avenieres, France, that will work on out-of-autoclave (OOA) technologies. This includes a joint effort with resin supplier Arkema to develop carbon fiber/PEKK tapes for next-generation aircraft programs.

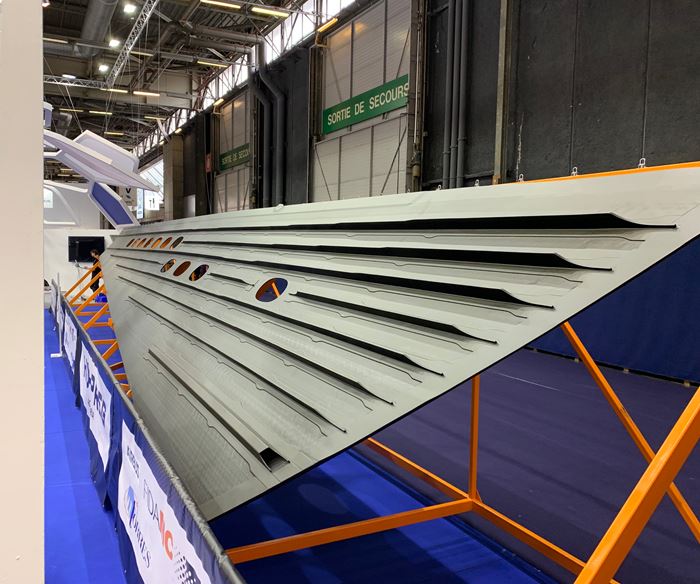

The largest composite structure at JEC World 2019 was an A380 empennage structure developed by Hexcel with FIDAMC (Getafe, Madrid, Spain) and MTorres (Torres de Elorz, Navarra, Spain) and intended to demonstrate the large-structure, high-rate capability of current AFP/ATL technology in commercial aerostructures (see photo). The MTorres machine used to fabricate the part, says Hexcel, has a laydown rate of 100-150 kilograms/hour and can place tapes up to 2 inches wide, enabling efficiencies heretofore not seen in aerospace manufacturing. Notable on the Hexcel stand was an integrated wing panel demonstrator (see photo), made with HiMax AS7 non-crimp fabric and infused with HexFlow RTM6 resin.

Soon after JEC World 2018, Hexcel announced a partnership with thermoplastics specialist Arkema (King of Prussia, Pa., U.S.) to develop carbon fiber/PEKK tapes for aerospace and other applications. That work, Hexcel reported this year, is ongoing and includes the development of a jointly operated Hexcel/Arkema lab that expected to open before the end of 2019.

New products announced at the show by Hexcel include:

- HexPly M901 thermoset prepreg, designed for automotive leaf spring applications

- HexPlay XF2, an in-mold surfacing product for wind blade manufacturing. It’s designed to obviate the need for gelcoat in wind blade fabrication and speed up manufacturing throughput.

- Polyspeed, Hexcel’s line of pultruded carbon fiber/polyurethane laminates for wind blade spar caps.

- HexAM, a CF/PEKK material for additive manufacturing applications that, Hexcel says, is expected to be a “major disrupter.”

- HexTow HM50, a new high-modulus, high-tensile strength carbon fiber.

- HexTow 85, a new Rayon-based carbon fiber for ablative applications, including solid rocket motor casings.

- HexBond, the new name for the line of adhesives products that Hexcel inherited when it acquired Structil.

- HiMax DPA (dot pattern adhesive) reinforcements are non-crimp fabrics (NCF) supplied pre-tacked, allowing multiple fabrics to be laid up more readily.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.