License to speed for composites manufacturing

RocTool pushes composites into new markets with its high-speed induction heating technology for molding.

RocTool demonstrated its 3iTech high-speed composites molding technology at

JEC (right) powered by two 50kW induction generators (left), which it also produces.

RocTool (Savoie Technolac, France) is an anomaly in the composites industry, not because of its astronomical growth — from revenues of $700,000 in 2010 to $7 million in 2013 — or its previous 10 years of R&D without revenues, but because it has truly achieved innovation in high-speed composites production — now claiming a mold heating world record of 60° to 160°C (140° to 320°F) in 5.3 seconds — and has succeeded, against all predictions, with its technology licensing business model, one which is difficult even for Microsoft. It is accomplishing all of this with a headquarters-based core staff of 30.

Founded in 2000, RocTool has 80 patents in 20 technology families with roughly 40 licensees worldwide, mostly major OEMS and Tier 1 suppliers. It astutely anticipated the opportunity in consumer electronics and via Taiwan-based licensee Ju Teng, now boasts use of its technology in one of the world’s largest smartphone and tablet parts factories in China, outputting around 10,000 parts per day. It also claims license agreements with five of the world’s top 10 manufacturers of 3C products (computers, communication and consumer electronics).

In fact, RocTool and Ju Teng were recognized, along with partner Complam (Taichung, Taiwan), with the JEC 2014 Innovation Award in Consumer Electronics, presented to Motorola Mobility (Libertyville, Ill., USA) for its MotoX and Ultra products. The MotoX rear housing is a molded polycarbonate (PC) composite reinforced with thermoplastic polyester (PET) fiber featuring a high-quality surface finish while the Ultra employs a 3-D unibody from the same composite but with Kevlar fiber added. The JEC award claims that combined production for both models exceeds 50,000 units per day.

RocTool was included in a second Innovation Award, this one to Expliseat (Paris, France) for its new Titanium Seat, claimed to be the lightest commercial aircraft seat on the market, weighing 4 kg (9 lb) per passenger place. The design, qualified for Boeing 737 and Airbus A320 aircraft, features titanium and composite tubes and uses RocTool’s 3iTech molding system to process TenCate (Almelo, The Netherlands) TC1100 polyphenylene sulfide (PPS) unidirectional composite tape reinforced with HexTow AS4 12k carbon fiber from Hexcel (Stamford, Conn.).

RocTool President Alexandre Guichard predicts the company's bespoke licensing agreements will number 100 within five years. However, he claims growth for its own sake is not RocTool’s priority, but instead it is focused on profitability first, and then technical support for worldwide licensees, including plans for subsidiaries in Germany and Japan as soon as possible.

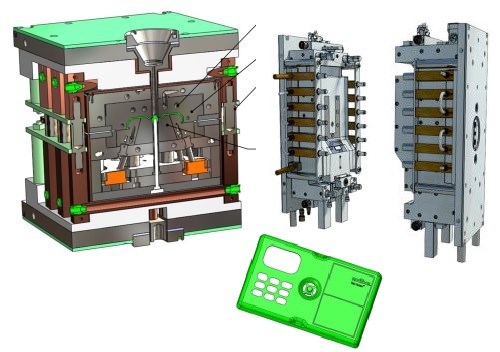

In RocTool's CAGE system, inductors (right) are positioned in two halves outside of the mold (left). They form a cage when electrically connected, instantaneously heating only the tool surface at a very rapid rate. CAGE is ussed for high-temp production of complex shapes (e.g., part at bottom). SOURCE: RocTool

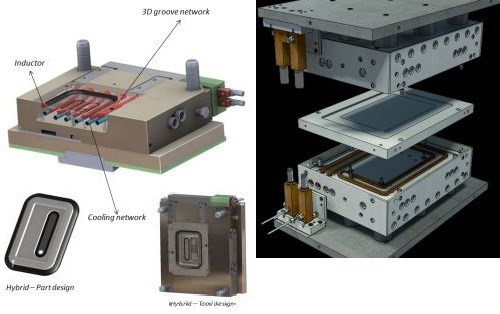

RocTool’s intellectual property (IP) strength comes from very fast heating and cooling via induction heating, seen in its Cage System and 3iTech technologies. In the Cage System, inductors are positioned in two halves outside of the mold, forming a cage when they are electrically connected. At this instant, the tool surface and only the tool surface heats rapidly. Cage is touted for production using high temperature, complex shapes and molds with moving features. 3iTech also uses inductors but placed inside the mold, similar to heating cartridges, but much faster and with a fraction of the energy consumption. Again, heating is within seconds and is for molding using localized or one-side only heating, seen especially with parts needing cosmetic and high-quality surfaces. RocTool also sells its induction generators, which range in power from 50kW to 300kW and may include cooling devices and automated remote control.

RocTool's 3iTech system uses inductors placed inside the mold,

again heating in seconds, but offering localized or one-side only heating

for parts requiring cosmetic surface finish. SOURCE: RocTool

RocTool demonstrated its 3iTech technology at JEC Europe (Mar. 11-13, Paris, France) by molding boomerangs from three different material combinations:

- Flax/polypropylene (PP)

- Recycled carbon fiber/glass fiber/PP CoDEP (fibers and thermoplastic co-deposited into a felt-like material) from MIT RCF (Asheville, N.C., USA)

- Glass fiber/ Thermoplastic polyurethane (TPU) from Bond-Laminates (Brilon, Germany).

The standard 100-ton press by Wabash MPI (Wabash, Ind., USA) achieved induction heating via copper coils inside the mold fed by two 50kW high-frequency induction generators, one for the top mold and one for the bottom. The molds could be heated and cooled — using a typical water system at 20°C (68°F) — from 50° to 400°C (122 to 752°F) and molded the boomerangs in 2.5 minutes. This type of system could be easily adapted for tools up to the size of an auto hood and has made cell phone parts. When asked about the timeframe from licensing to production, RocTool explained that engineering typically requires 2 to 4 weeks, followed by a few months for the mold tools to be fabricated and then a few weeks to establish production at the licensee’s site — i.e. less than six months for a simple, single-site installation.

RocTool demonstration of 3iTech molding technology with 2.5 minute cycle time at JEC Europe. SOURCE: CompositesWorld

RocTool has perhaps another trump card to play, an advantage few others in composites seem to offer: high-speed production using hybrid materials. Its technology and expertise spans composites, plastics and metals. Guichard gave an example in that Samsung and LG prefer “all-plastic” tablet and phone bodies while Apple and Lenovo have favored metal. In automotive, Volkswagen has avowed a hybrid approach including all three materials but favoring none. Guichard notes that metal has certain advantages but it is difficult to achieve fine thicknesses without extensive and costly surface finishing operations. He asserted that RocTool would have no problems finding customers for a technology which could produce metal parts less than 1mm (.04 inch) thick and a cosmetic surface quality. Perhaps that is one of their 10 dedicated R&D programs. In any case, there is little doubt that much more is to come from this small powerhouse with an ever-increasing global reach.

Related Content

BlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

Read MoreKraussMaffei unveils lab system for coating in the mold

ColorForm system brings injection molding machine, reaction process machinery, automation, post-processing and digital products in house.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreINN-PAEK project succeeds in 100% recyclable turbine

European project replaces complex-shaped metal structure in aircraft cooling system with injection molded thermoplastic composite material for improved sustainability.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More