Low-cost methods realize high-concept Superbus

Multifunctional mass-transport vehicle concept takes shape via resin-infused carbon/epoxy and vacuum-formed glass-reinforced thermoplastic sandwich construction.

Share

Read Next

In 2004, Prof. Wubbo Ockels of Delft University of Technology (TU Delft, Delft, The Netherlands) attempted a trip by train that became an unusually frustrating travel experience. After wasting hours waiting, he ultimately had to take other means of transportation to get to his destination. For most of us, that would be an experience to shrug off and forget, but for Ockels, an aerospace engineer and physicist at TU Delft who has flown on the Space Shuttle as a European Space Agency payload specialist, it was an audacious inspiration: What if you could be picked up at your doorstep and dropped off at the door of your destination by a multipassenger vehicle as comfortable as a limousine yet as fast as a bullet train?

Thus began the Superbus project, officially launched in 2006 after the concept won an innovative transportation competition designed to link Amsterdam’s Schiphol Airport and the city of Groningen. Granted €7 million ($9 million USD) by the Dutch Ministry of Transport and Public Works to prove the concept and produce a one-off demonstrator, Ockels and a team of private and public collaborators overseen by TU Delft is nearing that goal. Selected as the project’s chief designer, Dr. Antonia Terzi, the former head aerodynamicist of the BMW-Williams Formula 1 racing team and now the Aerospace for Sustainable Engineering and Technology (ASSET) chair at TU Delft, asserts: “Advanced composites are an absolute requirement to meet the performance objectives.”

Combining public and personal transport

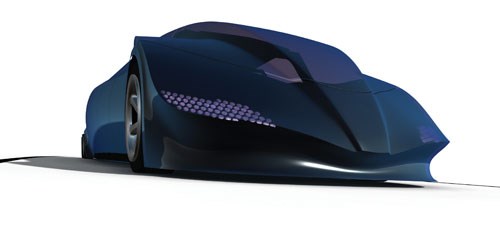

The motivating idea behind Superbus was to provide environmentally sustainable, point-to-point public transportation like that of a bus or train with the more private seating and convenience of a taxi or limo. The design effort, says Terzi, was constrained by only two factors: the vehicle’s length and width. “Everything else was wide open, which is what has made this project so exciting,” she notes. “I wanted to design a car-like environment within the envelope of a public vehicle.”Terzi also wanted the Superbus to be recyclable, have low power usage per passenger, and provide a high degree of safety for both passengers and the public. Design parameters, including aerodynamic drag, center of gravity, the propulsion system, the number of wheels and many others, ultimately pointed to intensive use of high-performance composite materials, which would minimize weight, maximize design flexibility and provide the necessary end-of-life recyclability.

The resulting 15m long, 2.5m wide and 1.65m high (49 ft by 8 ft by 5.4 ft) concept vehicle, piloted by a single driver, can cruise public roads to pick up and drop off as many as 23 passengers and then travel between cities on a dedicated “Super Track” at a speed of 250 mph/402 kmh or more. The 8,200 kg/18,000 lb prototype will be equipped with 16 doors (eight per side) that access three passenger cabins, but Terzi points out that future layouts could vary. Powered by a hybrid system of electric motors and rechargeable lithium/polymer batteries, Superbus also will employ anticollision radar sensors and a unique navigation system.

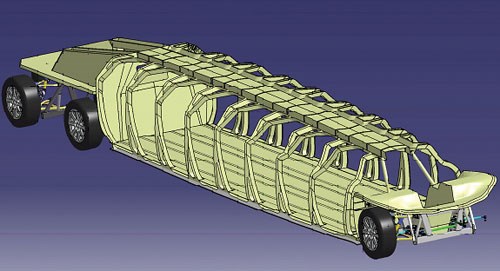

CATIA V.5 from Dassault Systemes (Paris, France) was used to render the vehicle’s components digitally. Terzi’s design called for an all-carbon/epoxy chassis to keep the overall weight as low as possible while delivering strength and stiffness, but she points out that the project’s mandate for individualized transport — giving a passenger the feel of a private limo in a public conveyance — made the design of the structural chassis “significantly challenging” because of the need to accommodate so many doors. Over a robust and complex floor, 16 curved and X-shaped cross-beams form the vehicle sides and support the 16 octagonal doors. Eight roof beams connect the cross-beams across the top of the vehicle. “We adopted the cross-beam design so that the entire vehicle cross-section can be used for torsional stiffness,” says Terzi.

The design complexity posed potential weight problems if the cross-beams were made in metal. “Making the cross-beams in composite,” she explains, “equates to a 40 percent weight reduction at the target stiffness when compared to a more conventional design with horizontal beams.” Completing the chassis is a forward carbon/epoxy cabin for the driver and a rear carbon/epoxy shell that encloses the power train and batteries. As a result, the overall chassis weight is a mere 1,300 kg/2,860 lb.

The exterior bodywork was designed with recently introduced material from SABIC (Riyadh, Saudi Arabia), developed by its U.S. subsidiary SABIC Innovative Plastics (Pittsfield, Mass.). Called IXIS, the moldable sandwich panel material consists of a random glass/polypropylene core between unidirectional glass/polypropylene skins. The lightweight panels offer a Class A surface finish and good impact strength. SABIC’s Lexan polycarbonate material was selected for the window glazing.

Vacuum infusing the chassis

In the wake of the formidable design process, production of the demonstrator parts for the Superbus has proven to be equally challenging, says Terzi. To meet the program’s budget and schedule, the team chose to fabricate parts via vacuum-assisted resin transfer molding (VARTM), which kept tooling lead times and material cost as low as possible. Although many of the Superbus’ components are being fabricated by subcontractors, TU Delft is responsible for part integration and fabrication of the vehicle’s doors and floor structure.

With VARTM in mind, the team specified dry Torayca 12K T700 carbon fiber (manufactured by Toray Industries Inc., Tokyo, Japan), which was converted by SELCOM Srl (Fregona, Italy) and Ten Cate Advanced Composites (Nijverdal, The Netherlands) into unidirectional tape and stitched triaxial (0°/+45°/-45°) fabric. According to Terzi, “The triaxial stitched fabric allows a more efficient layup than a standard fiber layup with rotated fabrics.” For the resin, an optimized infusion epoxy from Dow Epoxy (Midland, Mich.) was selected for its long pot life and very low viscosity.

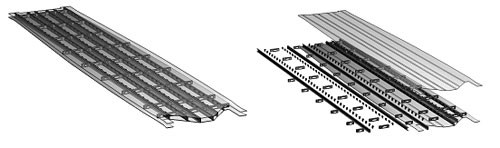

The floor consists of two 10m by 2.5m by 15-mm (32.5-ft by 8.1-ft by 0.6-inch) sandwich plates, top and bottom, separated by a series of longerons (lengthwise beams) and short transverse beams (both described later). The sandwich plates are produced on a flat metal mold using VARTM.

For the top plate, technicians lay down two plies of stitched triaxial carbon fabric skin material, followed by a 2-mm/0.08-inch thick Soric polyester nonwoven core material from Lantor Composites (Veenendaal, The Netherlands). Pressure-stable Soric material facilitates resin flow through the layup, but its hexagonal cell structure acts like a structural core when fully wet out. The layup, completed with the top skin plies of triaxial fabric, is then bagged and sealed and infused with the epoxy resin.

The bottom floor plate is made in the same way but includes several removable hatches to access electrical and hydraulic cabling beneath the floor. The hatches are layed up separately, using the same materials, on a flat mold. After they are infused, cured and trimmed, they are repositioned on the larger flat plate mold and covered with a polytetrafluoroethylene (Teflon) release film. Then the bottom plate is layed up and infused with the finished hatch covers in place to ensure that the plate and hatches will form a flush outer surface. Terzi says, “The floor plates have been optimized in terms of weight, height and stiffness with the Soric pressure-stable core material — we’ve carried out tests to ensure that the plate stiffness meets the performance targets as well as passenger comfort deflection targets.”

The six 10m/32.5-ft long longeron beams are vacuum infused in a simple U-shaped sheet-metal mold using patented techniques, developed by Lightweight Structures BV (Delft, The Netherlands), that help to ensure very low void content. The methods include heating and degassing the infusion resin and placing resin inlets at the beam radii, between the mold and the reinforcements, to ensure complete wetout and minimize any air entrapment or fiber bridging.

The 16 transverse beams are hand layed using prepreg — each beam is divided into seven small, hollow box beam segments of differing lengths that Terzi terms “shear links,” which fit between the longerons to support the passenger seats. The shear links are produced using carbon/epoxy prepreg layed up in box-shaped aluminum molds. Supplied by Delta Preg SpA (Sant’Egidio alla Vibrata, Italy), the prepreg is made by impregnating the same stitched triaxial carbon fiber fabric that is used in dry form for the other parts. During layup an aluminum mandrel insert is used to shape a central, oval-shaped hole in each shear link, which facilitates subsequent installation of wiring cables and air conditioning components that pass through the floor part. The layups then are oven-cured.

“We’re currently conducting a multiparameter study here at the university to determine which is the best fabrication technique for the future as we move forward into production,” Terzi adds.

To create the cross-beam molds, inexpensive polystyrene foam was first rough cut and then milled to shape with a 5-cm/2-inch offset for both the left and right side parts. Epoxy-based tooling paste was applied over the foam and allowed to cure at room temperature. The cured paste then was milled to the final mold contour and sealed to ensure a smooth, vacuum-tight tool face. The complexly curved yet slender beams (see photo, at right) require meticulous layup of more than 30 dry plies, a mixture of triaxial and unidirectional material, to ensure accurate fiber orientation, and the thick layup is difficult to infuse, Terzi reports.

The mold was intentionally designed so that the cured part would be cut in half lengthwise, each half demolded, then the two cut halves laminated together with wet layup plies. Terzi says that she and her students continue to investigate changes to the layup, the necessary cuts and the overlamination to optimize the process.

Revolutionary glass/thermoplastic body

For the body panels, the selected SABIC IXIS 157 glass/thermoplastic material consists of a random glass fiber-reinforced core (about 50 percent glass content) between continuous glass fiber-reinforced faceskins. Each faceskin is layed up from two plies of unidirectional glass fibers at 0° and 90° in a polypropylene matrix. According to Terzi, the material must be thermoformed to shape at a temperature too high for the materials used to make the VARTM tools. For the thermoforming molds, then, the team machined patterns, using the same polystyrene foam material and tooling paste, and then fabricated female or negative molds on the patterns using fiberglass tooling cloth and high-heat-resistant Daron unsaturated polyester resin from DSM Composite Resins AG (Schaffhausen, Switzerland). The IXIS material was layed in the negative molds, bagged and then heated in an oven to form the body and door panel shapes, Terzi reports. Vacuum pressure helps the heated material conform to the mold surface. “The parts made with IXIS composite sandwich material weigh half what they would in steel,” she notes, “but have equivalent stiffness.”

The chassis is assembled with a combination of adhesive bonding and metallic fasteners. The upper floor plate is bonded to the longerons and transverse beams using a 3M (St. Paul, Minn.) ScotchWeld epoxy adhesive, while the lower floor plate, with its access hatches, is bolted to the beams with stainless steel fasteners so it can be removed to give technicians access to the mechanical systems during upcoming vehicle tests. Side cross-beam parts are bonded and bolted both to the floor and to the roof beam elements.

Body panels are adhesively bonded to the chassis, together with the polycarbonate glazing for the windows, and passenger seats are made with carbon/epoxy prepreg. Safety features include a rear parachute for emergency braking and lateral deployable “morphing” structures — essentially flaps or spoilers that emerge from the body — that assist in braking. Among other innovations championed by Ockels, the dedicated Super Track highway will be geothermally heated to avoid any ice buildup on the roadway. To minimize aerodynamic drag at Super Track speeds, there are no door handles on the vehicle, only push buttons.

As this issue of CT went to press, the prototype vehicle was in final assembly and should make its inaugural appearance this year.

“The lightweight, highly streamlined construction of the Superbus means it will use the same amount of energy at 250 kmh as a normal collective vehicle does at 100 kmh,” concludes Terzi. CT will continue to follow this all-composite advanced transport concept as it moves toward its first trial on the Dutch Super Track.

Related Content

Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreHenkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MoreHenkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)