Marine resurgence – with carbon?

The marine market took a big hit during the Recession, but it's been recovering since, and there are signs that carbon fiber might be leading the way.

Video: How Prisma preforms, from Compsys, are used in boat frame manufacturing.

Several years ago, we published a story in Composites Technology magazine (October 2010, link here: www.compositesworld.com/articles/marine-composites-a-new-dawn) about the state of the marine industry. The Great Recession that began in late 2007 (and arguably may be continuing today) hit a lot of end markets hard, and in particular, the marine industry. The bottom fell out of the boatbuilding market in late 2008. According to the National Marine Manufacturers Assn. (NMMA, Chicago, Ill. USA) president Thom Dammrich, as sales of new boats dropped, production dropped even faster, leading to a plunge of wholesale boat sales of 80 percent in 2009, compared to 2008.

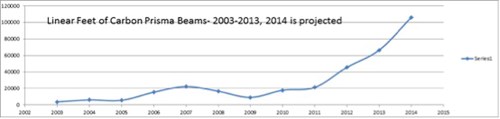

But, recovery is occurring. A CompositesWorld blog posting from last summer (link here: www.compositesworld.com/blog/12) reported some encouraging statistics. And a well-known industry expert, Scott Lewit, who is president of Compsys (Melbourne, Fla., USA) and sister company Structural Composites Inc., says that his company is seeing a “very significant uptick” in the number of production recreational boats that are using Compsys’ carbon fiber Prisma preforms as stringers and beams in hull structure. The chart, provided by Lewit, shows the upward trend.

Says Lewit, “It’s interesting to look at this and think about boating industry. It peaked in 2005 and was declining till the bottom fell out in late 2008. The next year, 2009, was about 20 percent of 2005. Today it’s 35 to 45 percent of 2005, so clearly we are bucking the trend.”

Lewit is known for advocating a switch from traditional sandwich hull design to a “single skin membrane” design, with low-section framing. The relatively flexible single skin transfers flexural hull loads to the preformed Prisma frames, for an overall lighter structure that ultimately saves cost. See a previous story on this design approach for the U.S. Navy’s rigid-hulled inflatable boats (RHIBs), done by Lewit’s company with Zodiac Boats (Stephensville, Md., USA) at www.compositesworld.com/articles/re-inventing-the-rhib-shock-mitigation.

Lewit is seeing solid evidence of greater penetration of carbon fiber, in the form of Prisma structural preforms for “many thousands of boats,” into recreational boating. That jives with reports and predictions of others, particularly in the racing and superyacht sectors. A market report released a few weeks ago by Transparency Market Research (Albany, N.Y., USA) cites development of the boat building industry in China, South Korea and Oceanic region as likely to be one of the key factors driving the demand for marine composites, and carbon composites, over the next few years.

Related Content

-

Orbital Composites installs robotic AM system at University of Rhode Island

The 12-axis Orbital S system designed to print continuous fiber-reinforced parts will be used to advance research in composites for underwater unmanned vehicles.

-

Mel Composites infusion strategy enables Sasga Yachts fiberglass hull designs

Mel’s ongoing partnership culminates in the development of the Menorquín 42 and Menorquín 54 motor yachts, as well as extension of Sasga’s capacity for 68-foot-length boats.

-

Evolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.