McDonnell Douglas composite cryotanks — a personal history

Composites industry veteran Bob Hartunian looks back on a bold effort in 1987 to develop a thermoplastic composite cryotank for hydrogen storage. It gets complicated.

A recent article in CompositesWorld about cryogenic tanks (“An update on composite tanks for cryogens”) brought back memories of my involvement with the same issues 20 years ago. I was working at McDonnell Douglas in Huntington Beach, Calif., U.S., in 1987 and was asked if it was possible to build a reliable composite cryotank for the National AeroSpace Plane program (NASP). The NASP plane was to be powered by a scramjet engine and needed a considerable amount of liquid hydrogen fuel for each flight. Versions of the NASP were even envisioned to carry paying passengers, so the structure had to work very reliably and light weight was mandatory.

No one had ever built a composite cryotank except the Russians, who during the 1970s made a tank that was so heavy it wasn't feasible to fly it, plus it leaked badly. So, loving a composites challenge, I gave them a firm "maybe" and was given the job of building a tank pronto because Rockwell and General Dynamics were also in competition for the NASP contract. The carrot here was that the U.S. Air Force would award the NASP contract to whoever could make a working tank first.

We knew that the critical element wasn't just containing liquid hydrogen at a temperature of -423°F/-253°C for a single fill/drain cycle, it was keeping the tank intact and leak-free after multiple fills and drains, where the tank would see a temperature range of 800°F/427°C (from its 350°F/177°C cure temperature to -423°F/-253°C for each cycle). These cycles would likely produce microcracking that would cause leakage and eventual structural failure.

The choice of thermoplastics

The wisdom of the day was that PEEK (polyetheretherketone) thermoplastic resin, with its higher strain-to-failure characteristic compared to 5208 (Narmco) or 3501-6 (Hercules, now Hexcel, Stamford, Conn., U.S.) epoxy systems, might be our best choice. This information came from the National Bureau of Standards (Denver, Colo., U.S.), which supposedly had done work in this area (though no actual data was available). Therefore, the decision was made to go with PEEK. The best fiber around was Hexcel’s IM7, so we ordered IM7/PEEK prepreg tape in 5-mil (0.005-inch) thickness.

I started to ask questions about processing this material and got surprised fast. First, it cured at more 700°F/371°C, which forced you into steel tooling with a high thermal mass for slow heating/cooling rates. But the PEEK also needed fast cooling to control its microstructure for the best properties. Next, it required high compaction pressures — about 150-200 psi (10.34-13.79 bar), because it wouldn't flow due to very high viscosity.

There were no vacuum bagging materials or sealants that would take the high and prolonged processing temperatures and pressures. And the material had no pliability at ambient temperature, so each ply had to be tacked to the one below with a soldering iron — at 900°F/482°C, no less. Then the Air Force mentioned that it didn't like it being bonded either. PEEK wasn't user-friendly.

Zany tri-lobe tank design

All these issues were combined with a tank design that Burt Rutan would run from. Our designers had to maximize tank capacity inside a fuselage surface shaped like a sine wave. The tank needed to be tri-lobed, 10 feet long, 6 feet wide, and 3 feet high (3 by 1.8 by 0.9 meters), with a 900-gallon capacity within paper-thin walls (.030-inch/0.76-mm in thickness) and have flat ends — the worst possible design for pressure containment.

The thin skins needed external support tubes to keep the tank from deforming under pressure. To minimize any leak paths, the lobed tank had to be made in one piece and end bulkheads adhesively bonded, as any fasteners would almost certainly create leak paths. Plus, it had to have all the plumbing inside (to fill, drain, pressurize, show fuel levels) and it all had to work perfectly — and we had to do it all in 10 months. Me and my big “maybe”!

The design group rushed to produce tank dimensions quickly so we could begin tooling. The steel tool was built on a rotating spindle so the composites shop could turn it during layup of the skins. While this was going on, we began a fast learning program, building a subscale tank from PEEK in the lab. We found that DuPont's polyimide Kapton film (at the time, DuPont High Performance Materials, Circleville, Ohio, U.S.) would take the temps and General Sealants Inc. (City of Industry, Calif., U.S.) had sealing tape that would soften at 400°F/204°C. If we used a conventional sealant plus the GS material as a double sealed tape system, we could hold vacuum at 700°F/371°C. What we didn't realize then was that the subscale tank heated and cooled much more quickly than the full-sized tank, so not all the learning was correct and applicable.

Managing permeation and second thoughts

Meanwhile, the labs were trying to measure the hydrogen permeation rates of PEEK laminates under cold pressure to see just how good this material was and whether some liner inside the tank was required to stop leakage. Now I was really concerned with our ability to autoclave cure this tank after seeing all the processing problems, and I began to wonder why PEEK had become the chosen material. It must have been its toughness or the ability of the resin to tolerate the thermal strains without cracking.

So, if we used a conventional, high-temperature 350°F/177°C thermosetting resin with similar toughness or strain-to-failure, maybe an epoxy would work equally well and be much easier to process. During permeation testing, we also tested some of the new IM7/8551-7A epoxy-based material we got from Hexcel and when the test results came in the epoxy was the best! Since the program was focused on using PEEK laminates, even though the IM7-8551-7A material had better permeation behavior, the program continued with PEEK as the baseline.

Heavy tool, hot autoclave, a leak and peeling paint

When the skin shell layup was complete, one problem remained. The sine wave design had concave surfaces where the stiff PEEK material wouldn't remain in place when draped onto the mold surface, and it kept popping off. Try as we could with soldering irons, the PEEK always tore loose. One night, I came up with an idea: suppose we bonded the ply down with epoxy and let it burn off during the 700°F/371°C cure? Would the laminate suffer issues or would it work? In three days, I had my answer. We bonded those pesky plies in place and, after cure, compression tests showed no damage from the burned epoxy.

When it came time to cure the shell, we didn't have a suitable autoclave in Huntington Beach. The closest was in Mesa, Ariz., U.S., at our helicopter facility. They had never taken it up to 800°F or elevated pressure but allowed us to come in. The delivery truck transported the tool and bagged layup through the August desert heat and by the time it arrived, the portable vacuum pump had died and the vacuum bag on the part was hanging down on the floor.

We moved this 12,000-lb load off the truck onto wheels that immediately sank into the softened asphalt roadway and formed deep grooves as we dragged it into the shop. I could tell our hosts were not too pleased with us — and then things got worse. We loaded the part into their autoclave and turned on the heat/pressure. All looked good up through 500°F/260°C. By 600°F/316°C and after eight hours of heating, we began to see a rise in pressure under the bag, indicating the start of a leak, but it was too late to stop and perform a bag repair.

By 700°F/371°C, the internal bag pressure was close to 50 psi/3.45 bar. We had a major leak and, as a result, a reduction in the compaction pressure needed to consolidate the part properly. I made a judgment call to increase pressure and temps, trying to outrun the leak and get consolidation. By 800°F/427°C and 200 psi/13.79 bar, we had redlined the autoclave and it was close to midnight. We had to dump everything to try getting anywhere close to the 10°/min cooling rate the PEEK supplier called for. The autoclave was vented at maximum settings — the blast of escaping nitrogen could be heard back in L.A. What I didn't realize was that the hot gas had reached the walls of an adjacent building and burned its exterior paint off. Needless to say, we were not invited back to Mesa again.

Switch to epoxy

No matter what we did, the quality of the PEEK parts was not up to aerospace standards. Finally, after six months of hard work, we switched to epoxy. In the following four months, we made an entire tank with all the detail parts, and bonded the ends to seal the tank with film adhesive. During a strain gage installation for the cryo performance measurements, the technician left a heat lamp on and burned a six-inch hole in my precious tank! We patched it by injecting low-viscosity epoxy in delaminated areas, cut out burned sections and did a staggered prepreg layup over the cutout area. During subsequent testing, the repair never leaked.

One year after we started, we placed the tank inside a fuselage section made from titanium aluminide, filled it with liquid hydrogen, heated the fuselage to 1300°F/704°C, pressurized the tank to >100 psi/>6.89 bar and added torsional and bending loads to the assembly. Mass spectrometer sensors did the hydrogen sniffing, with no detectable leaks. This was the first composite tank to successfully hold liquid hydrogen, and more fill/drain cycles followed without leaks. Meanwhile, our competitors were concentrating their efforts on material evaluations and didn't come close to building anything like a working tank.

Unfortunately, programs come and go in this business — NASP eventually was canceled because of cost and the other technical issues that still needed to be addressed, especially with the engines. But I was happy with our work and proud of what we accomplished.

Editor’s note: Bob Hartunian is a retired Boeing Technical Fellow. He logged 32 years in the composites manufacturing business, first at McDonnell Douglas in Huntington Beach, Calif., and then The Boeing Co. (Seattle, Wash.), when McDonnell Douglas became part of Boeing.

Related Content

Queen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreClean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

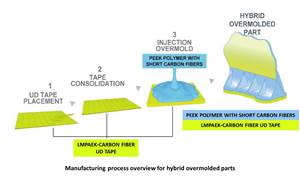

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)